Reznor REC (Evaporative Cooling) Unit Installation Manual User Manual

Page 7

Form I-REC, P/N 160201 R3, Page 7

Sequence of Operation for Optional Kits:

Applies to: Float and Pump System with Optional Fill and Drain Kit

(Option CT1, CT2, or CT3)

1) Call for cooling.

2) 2-way valve is energized and closes B to A.

3) 3-way valve is energized opening B to C and closing A to C.

4) During no call for cooling, valves return to normal state.

Applies to: AquaSaver Timed Water System with Optional

Freeze Protection (Option CT5)

1) Call for cooling.

2) 3-way valve is energized opening B to C and closing A to C.

3) If outside air temperature drops below freeze protection controller

setting, 3-way valve is de-energized and AquaSaver 24V solenoid valve

remains energized for eight minutes to allow complete system water

drainage.

4) During no call for cooling, 3-way valve returns to normal state.

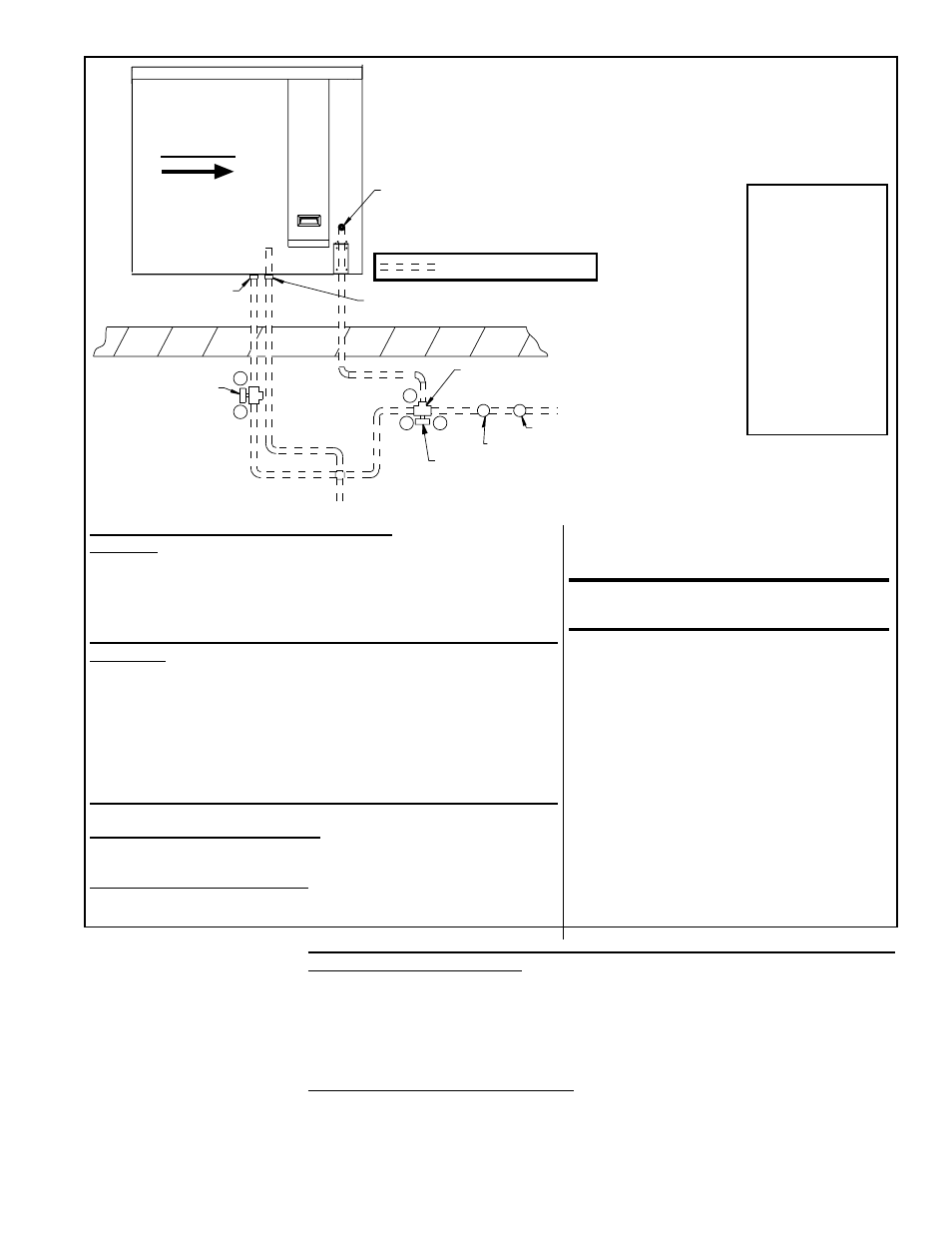

Evaporative

Cooling

Module

Inlet Water Connection -

1/4compressionfitting to

the float or 1/2 male NPT

fitting for AquaSaver

Overflow Fitting - 3/4 male NPT

tapped with 1/2 female NPT

Drain Fitting -

3/4 male NPT tapped

with 1/2 female NPT

2-Way Solenoid Valve

(normally open)

1/2 female NPT

(A 2-way valve is in

Options CT1, CT2, and

CT3. 2-way valve in

drain does not apply

to AquaSaver freeze

protection Option CT5.)

To Drain

3-Way Solenoid Valve (valve is suitable for a maximum close-off pressure

differential of 25 psi and a system static pressure of 300 psi) - 1/2 NPT,

2-position spring return (normally closed at B port)

(A 3-way valve is in fill and drain kit Options CT1, CT2, CT3,

and freeze protection Option CT5.)

Actuator must be above the valve body when

mounted in horizontal piping.

Roof

Water Inlet

Field-supplied Service Valve

Field-supplied Pressure Regulator (if required)

A

A

B

B

C

= Field-installed Water Piping

Left Side View

Water Line Connections (See illustration.):

Supply (3-Way Valve) Connections - Connect the water supply line to “B”

(normally closed). Connect the water drain line to “A” (normally open). Con-

nect the middle outlet “C” to supply the water to the cooling module reservoir.

Drain (2-Way Valve) Connections - Connect the drain pipe from the reser-

voir to “B”. Connect the outlet side to “A” and connect into drain lines from

the cooling reservoir and the supply valve.

Electrical Connections (requires black

and white 14-gauge wire) - Refer to Wiring

Diagram provided with the furnace:

WARNING: Risk of electrical shock.

Disconnect the power.

1. Refer to the wiring diagram for terminal

connections. (NOTE: If kit is not ordered with

the system, connections will not be shown on

the diagram. Terminal connections are specific

to each system. Contact the factory for

terminal connections. Be prepared to provide

all model information.)

2. Run field-supplied black wire from the

electrical compartment (terminal on the wiring

diagram) of the evaporative cooling module

and connect to the black wire on both the

3-way and the 2-way valve.

3. Run field-supplied white wire from the

electrical compartment (terminal on the wiring

diagram) of the evaporative cooling module

and connect to the white wire on both the

3-way and the 2-way valve.

NOTE: Follow

instructions

included in the

valve packages

for attaching

valves to the

water line only.

The remainder

of the installation

instructions with

the valves do not

apply to this type

of application.

FIGURE 9 - Water Connections including Optional Fill and

Drain Kit for a Float and Pump Control System and a Freeze

Protection Kit for an AquaSaver Timed Metering System

NOTE: If installing a Size REC360, one fill and drain or freeze protection

kit may be used for both modules if lines are manifolded.

Filling and Adjusting the Water Level in the Reservoir (module equipped with

pump and float controls only) – Turn on the water supply. Check for a good flow.

When the float valve (

FIGURE 6) shuts off the water supply, measure the water depth.

The depth of the water should be approximately 3”. It may be necessary to adjust the

float valve to obtain the proper water level or to free the float valve from obstructions.

To adjust the float valve, simply bend the float valve rod upward to raise the water level

or downward to lower he water level.

Check for Water Leaks - All Modules - The reservoir was water tested but should be

checked again for small leaks. If any leaks are present, dry the reservoir and apply a

field-supplied waterproof silicone sealer around corners and welds.

Proper water flow over the evaporative cooling media is critical to extend the life and

maintain the efficiency of the pads.