0 controls – Reznor ADFH Unit Installation Manual User Manual

Page 21

Form I-ADF, P/N 131805 R5, Page 21

When a console with a dirty filter indicator is selected, the remote console includes a

fourth light (dirty filter indicator light). The light is activated by an adjustable, single-

pole/normally open differential pressure switch that senses air pressure across the

filter bank. There are field-installation procedures that must be done for proper opera-

tion of the dirty filter indicator light.

Dirty Filter Switch Installation Instructions

Before the system is operating, connect the sensing tubes from the switch to

their sensing locations in the field-installed filter cabinet.

1) Run the tubes through the holes in the cabinet wall. Pull gently to extend the

tubing to its entire length without stress.

2) Position the tubing approximately at the center of the height of the filter rack.

3) Identify the tube connected to the positive connection on the switch (

FIGURE

23) as the positive pressure tube. Determine the length of tubing required to

attach the

positive pressure tube so that it will sense pressure at the inlet

side of the filter rack.

Identify the tube connected to the negative connection on the switch (

FIGURE

23) as the negative pressure tube. Determine the length of tubing required to

attach the

negative pressure tube so that it will sense the pressure at the

blower side of the filter rack.

(

NOTE: Tubing shipped is the same length for all sizes of systems; cut to the

appropriate length for the smaller systems.)

4) If required, cut the tubing to the proper lengths. Using the clamps provided,

attach the ends of the tubing to the filter rack at about center height being care-

ful not to kink or compress the tubing.

After the system is operating, the filter switch must be manually set. With

clean filters in place, blower doors closed, and blower in operation, increase the

pressure setting by adjusting the set screw on the switch clockwise until the filter

light is energized or the screw is bottomed out. At that point, adjust the set screw

three full turns counterclockwise or until the screw is top ended. At that setpoint,

the filter light will be activated at approximately 50% filter blockage.

Dirty Filter Light

(on the Remote

Console)

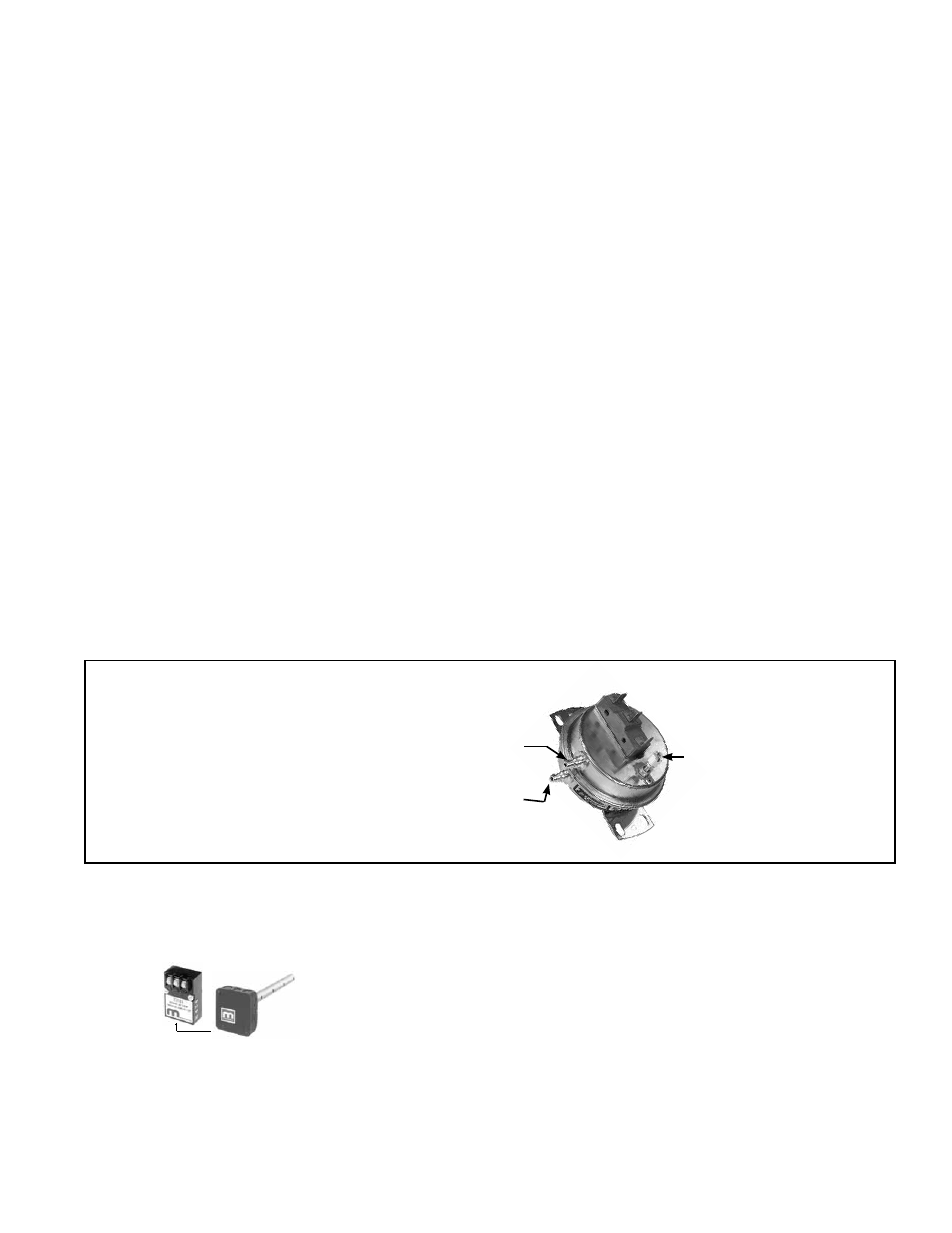

FIGURE 23 -

Dirty Filter

Pressure Switch

Set screw (on front

of switch) must be

manually adjusted after

system is in operation.

Negative pressure connection

is toward the "front or top" of

the switch (senses blower side

of filters)

Positive pressure connection is toward the

"back or bottom" of the switch (senses air

inlet side of filters)

Discharge Temperature Sensor (Maxitrol) for Gas Control Options AG30,

AG31, AG32, AG33, and AG36

A discharge sensor may be shipped separately for field installation. Attach the dis-

charge sensor and mixing tube in the ductwork about six feet (1.8 M) from the dis-

charge opening of the system.

The sensor housing is not waterproof. If the installation is outdoors, field-fabricate a

waterproof protective enclosure for the discharge sensor, being careful not to affect its

air temperature sensing capability.

Refer to the wiring diagram and connect the sensor to the terminal strip in the blower

section electrical box. Use shielded wire to alleviate any electrical interference that my

cause an erroneous discharge temperature reading.

Outside Air Cutoff Control (Option BN2)

After sensing pilot flame, the burner ignites at its lowest input rate. The "amount of

heat" required to reach the desired discharge temperature also depends on the tem-

Discharge

Sensor

and

Mixing

Tube

8.0 Controls