4 blowers, drives, and blower motors, 0 electrical and wiring, 1 general – Reznor ADFH Unit Installation Manual User Manual

Page 19: 2 supply wiring

Form I-ADF, P/N 131805 R5, Page 19

Motor Pulleys and Blower Speed - Units are set at the factory for the RPM required

to meet the CFM and external static pressure specified on the order. If the estimated

external static is incorrect, or changes are made to the duct system, the blower RPM

may have to be changed. Motors are equipped with adjustable pitch pulleys which

permit adjustment of blower speed. Instructions are included in Paragraph 9.2, Startup,

for adjusting blower speed.

Blower Rotation - Each blower housing is marked for proper rotation. Checking blower

rotation is included in Startup, Paragraph 9.2

Motor Loads - Use an ammeter to check motor amps. Amps may be adjusted down-

ward by reducing blower RPM or by increasing duct system static pressure. The open

motor amp chart below can be used for sizing line wiring. For accurate amps, read the

motor manufacturer's rating plate; amps will vary depending upon type of motor and

motor manufacturer.

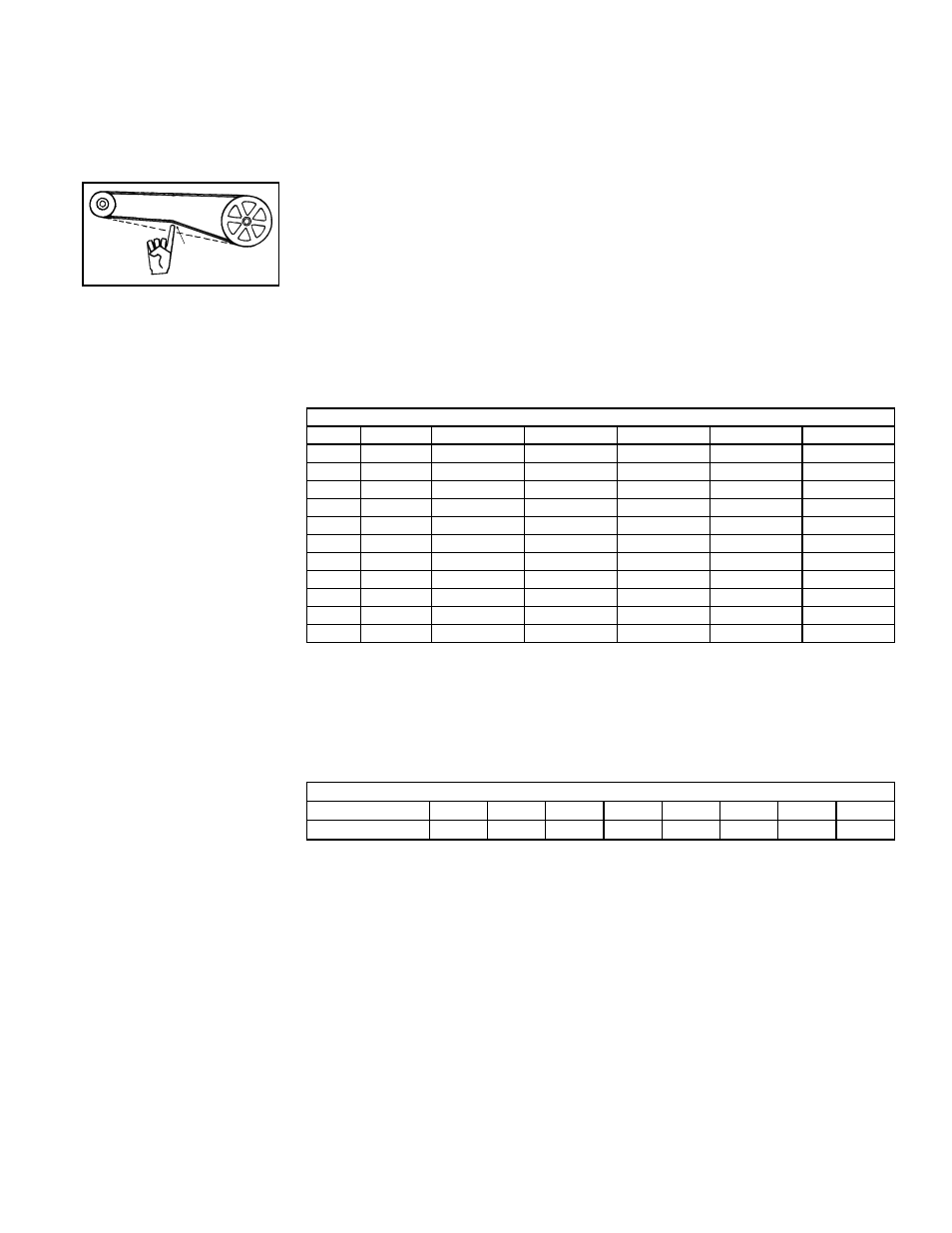

FIGURE 20 - Belt

Tension

6.4 Blowers, Drives,

and Blower

Motors

Check belt tension. Proper belt tension is important to the long life of the belt and

motor. A loose belt will cause wear and slippage. Too much tension will cause exces-

sive motor and blower bearing wear. If adjustment is required, adjust belt tension by

means of the adjusting screw on the motor base until the belt can be depressed 1/2" or

3/4" (

FIGURE 20). Be sure the belt is aligned in the pulleys.

3/4

(19mm)

Blower Motor Full Load Amps (open motors)

HP

115/1

230/1

208/3

230/3

460/3

575/3

1/2

8.8

4.4

2.1

2

1

--

3/4

11

5.5

2.9

2.6

1.3

--

1

13

7.5

3.7

3.2

1.6

1.4

1-1/2

15

7.5

5.6

5

2.7

2

2

N/A

N/A

7

6.6

3.3

2.4

3

N/A

N/A

9.1

8.4

4.2

3.6

5

N/A

N/A

13.4

13.2

6.6

5.4

7-1/2

N/A

N/A

22

21

10.5

8.4

10

N/A

N/A

30

26

13

10.4

15

N/A

N/A

43.1

39

19.5

16

20

N/A

N/A

58.7

53

26.5

21.2

7.0 Electrical and

Wiring

7.1 General

All electrical wiring and connections including electrical grounding MUST be in accor-

dance with the National Electric Code ANSI/NFPA No. 70 (latest edition) or the Cana-

dian Electrical Code part 1-C.S.A. Standard C22.1 Check and comply with any local

ordinance or utility company requirements that apply.

7.2 Supply Wiring

Wire Gauge Sizes - 100 ft maximum

FLA

5

10

15

20

25

30

35

40

Wire Gauge

14

14

12

10

8

8

6

6

Run a separate line voltage supply directly from the building electrical panel to the

disconnect switch for the system. All external wiring must be within approved conduit

and have a minimum temperature rise rating of 60°C. For motor load amps, check the

motor nameplate.

Specific wiring diagrams and complete instructions are packed with each unit and

should be kept readily accessible in legible condition.

Disconnect Switch - A safety disconnect is required. An outdoor installation requires

a weatherproof disconnect switch. Install either an optional UL-listed disconnect or a

field-supplied equivalent. Install the disconnect switch in accordance with Article 430

of the National Electrical Code ANSI/NFPA 70 or in accordance with Canadian Electri-

cal Code Part 1-C.S.A. Standard C22.1. When attaching the disconnect switch to the

heater, use hardware with "teeth" to provide electrical grounding. The "teeth" should

face the disconnect switch, scratching off the painted surface. Attach the disconnect

tightly against the heater cabinet. (Refer to

FIGURE 21.)

When providing or replacing fuses in a fusible disconnect switch, use dual element

time delay fuses and size 1.25 times the maximum total input amp as stated on the unit

rating plate.