Reznor ADFH Unit Installation Manual User Manual

Page 15

Form I-ADF, P/N 131805 R5, Page 15

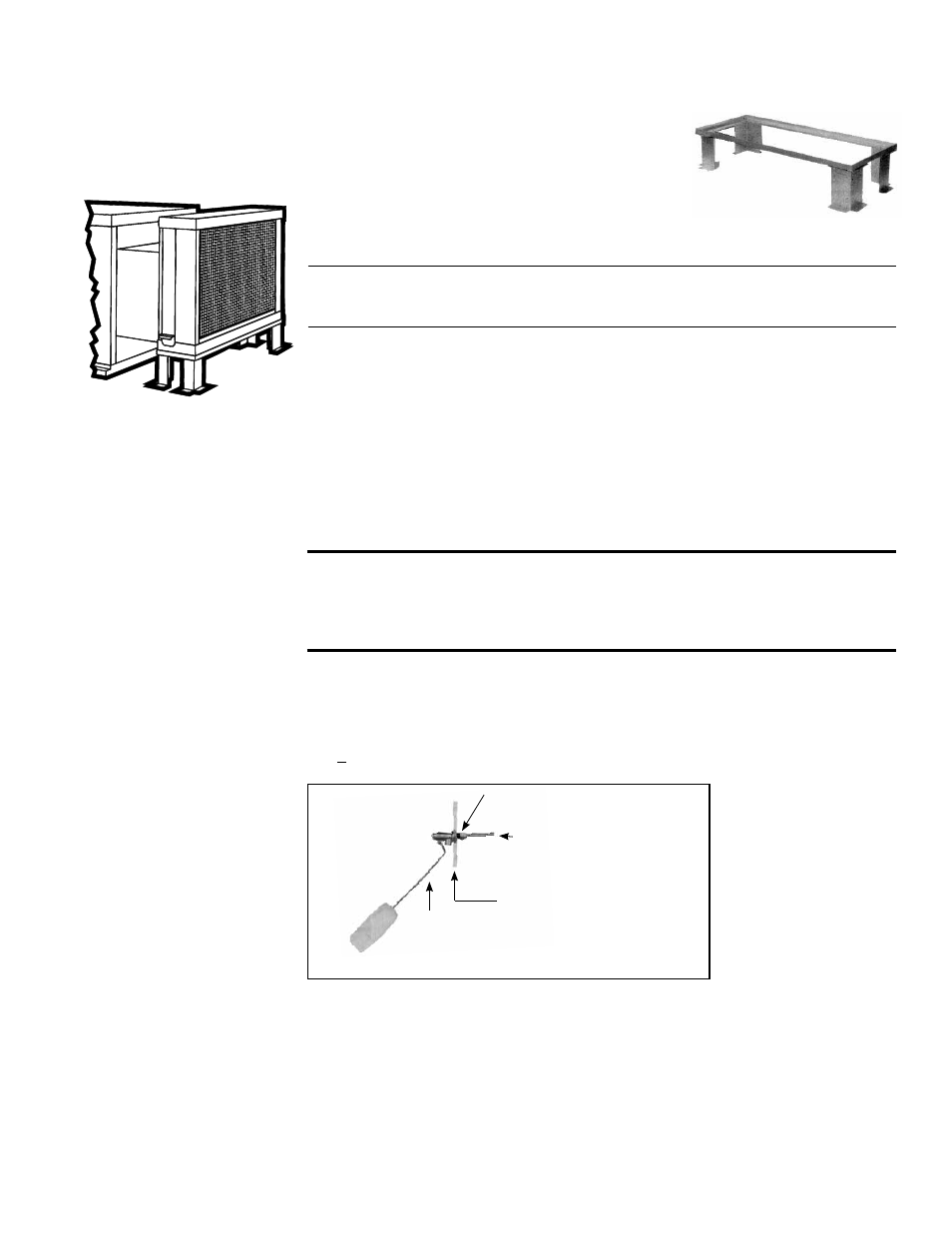

FIGURE 12 - Optional

Evaporative Cooling

Module on an ADF/

ADFH 700 or 1200.

Assembled module is

shipped separately for field

installation.

an adjustable base, and the transition ductwork between the cooling module and the

cabinet. Complete installation instructions including dimensions are packaged with the

evaporative cooling module package.

Included in the cooling module installation

booklet is a preparation checklist. All items

in that checklist should be addressed prior

to beginning installation of the evaporative

cooling module. Four of those items are

listed below.

Make certain the roof or platform is

capable of handling the additional load of a full cooling module reservoir.

Wts of Evaporative Cooling Module w/ Wet Media & Full Reservoir

Module with 12" rigid cellulose media (Option AS4) . 431 lbs (196 kg)

Module with 12" rigid glass fiber media (Option AS8)

514 lbs (233 kg)

Make certain the roof is level and free of debris where the cooling module will be

mounted.

Do not mount directly on soft tar roofs where the legs could sink and tilt the cooling

module. Provide a weather-resistant, solid wood or metal base under the cooling

module support legs.

Make certain that there will be adequate clearance between the bottom of

the reservoir and the roof (or platform) to allow for drain and overflow pipe

connections.

All Sizes - If an optional fill and drain kit is part of the installation, the kit is shipped

separately. Connect the fill and drain kit as illustrated in

FIGURE 14.

Adjustable Leg Height

16" maximum; 9" minimum

Float

Valve

Rod

Compression Nut

and Tubing Ferrule

Use 1/4" Tubing for

Fresh Water Supply

Simulates Cabinet

Side Panel

FIGURE 13 - Connect

Fresh Water Supply to

Inlet of Float Valve

(Inside the

Cabinet)

Evaporative Cooling

Module Water

Connections and

Adjustments

WARNINGS: Water reservoir must be drained and pump motor

turned off when outside temperature falls below 32°F. Pump must

never be operated without water in the reservoir. See Hazard

levels, page 2.

Supply and Drain Water Connections

Float Valve (FIGURE 13) - In a module with pump and float controls, a float valve

maintains the appropriate water level in the reservoir.

Use a field-supplied 1/4" diameter tubing with a compression nut and tubing ferrule to

connect the fresh water supply to the inlet of the float valve. See

FIGURE 13. Place nut

and ferrule over tubing and insert tubing into the float valve stem. Tighten nut securely.

AquaSaver

®

Timed Metering Control System - If the cooling module is equipped

with an optional timed metering system, connect a 1/2" water line to the fitting on the

side of the cooling module.

Due to various water pressures and installation conditions, the water supply line may

bang abruptly when the solenoid valve in the AquaSaver system closes. This banging

can be minimized by installing an optional water hammer arrestor in the supply line. If

installing an optional water hammer arrestor, select an indoor (above 32°F) location,

either horizontal or vertical, in line with and as close to the solenoid valve as possible.

Follow the manufacturer's instructions to install and maintain the water hammer arres-

tor.