Out of production – LAARS Mighty Max HH (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 9

Mighty Max Hydronic Boiler

Page 9

tubes. Boilers installed in violation of the foregoing

may void the warranty.

2.7.5 Combined Space Heating/Potable

Water Heating Systems

When using the Mighty Max boiler as a source

of heat for a combined space heating/potable water

heating system, be sure to follow the instructions of

the space heating system.

Do not use water piping, fittings, valves, pumps,

and any other components which are not compatible

with potable water.

Do not connect the heater, which will be used to

supply potable water, to any heating system or

components previously used with a nonpotable water

heating system.

Do not add boiler treatment or any chemicals to

the heating system piping, since the piping contains

water for potable use.

Do not use solder containing lead in the potable

water lines.

Some jurisdictions may require a backflow

preventer in the cold water line. In such cases,

pressure relief valve may discharge water due to

expansion. An expansion tank approved for potable

water will eliminate this condition. Follow the

manufacturer's instructions for installation of the

expansion tank.

2.8 Piping of System to Boiler

1.

Be sure to provide gate valves at the inlet and

outlet to the boiler so it can be readily isolated

for service.

2.

The pressure relief valve installed in the tapped

opening provided in the outlet header must be

piped, but not fastened, to a drain or floor sink.

The drain pipe must be the same size as the valve

outlet and must pitch downward from the valve. If

the PRV supplied with the boiler is not factory

installed, install it in the front header consistent

with the ANSI/ASME Boiler and Pressure Vessel

Code, Section IV. Pay special attention to relief

valve settings in installations where the boiler is

located on the ground floor of a tall building, or

where the operating temperature of the boiler is

above 210°F (99°C). In both instances, the static

pressure of the system is elevated and could cause

the relief valve to leak and bring considerable raw

water into the system. Where no special setting of

the relief valve is ordered, the factory will furnish

a 75 psi (511.5 kPa) setting. Never reduce the

relief valve opening. If necessary, install the relief

valve in a Tee immediately past the boiler outlet.

3.

Provide a boiler installed above radiation level

with a low water cutoff device either as part of

the boiler or at the time of boiler installation (see

Figure 7).

4.

Install manual and/or automatic bleeding devices

at high points in the system to eliminate air.

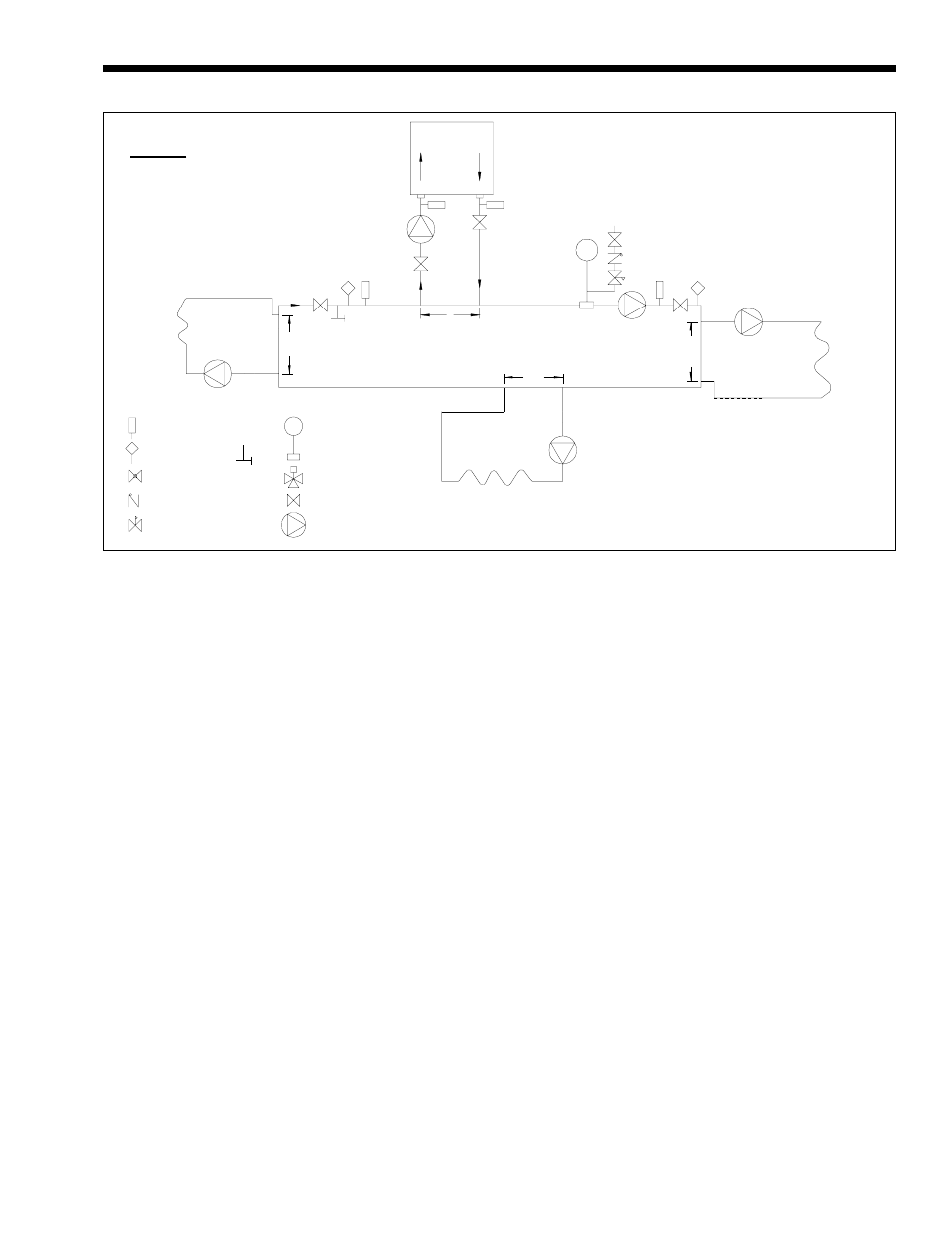

Figure 5. Primary-Secondary Plumbing.

Boiler Circulation

Pump

Cold Water

Make-Up

System Pump

12"

Max.

12"

Max.

12"

Max.

12"

Max.

Thermometer

Temperature

Sensor

Globe Valve

Check Valve

Pressure Reducing Valve

w/Fast Fill Bypass

Expansion Tank

with Air Scoop and

Auto Air Vent

3-Way Valve

Valve

Pump

LEGEND:

Boiler circuit piping must be equal to or larger

than boiler water connection size.

Boiler circulation pump sized for flow through

boiler.

Dotted devices indicate alternate locations.

WARNING: This drawing shows suggested

piping configuraiton and valving. Check with

local codes and ordinances for additional

requirements.

Purge

Valve

OUT OF

PRODUCTION