Out of production – LAARS Mighty Max HH (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 15

Mighty Max Hydronic Boiler

Page 15

2.13Air for Combustion and Ventilation

The boiler requires air for combustion and the

space around the boiler requires ventilation.

Combustion air can be provided by standard practices

as specified in the installation codes (ANSI Z223.1/

NFPA 54, in Canada, CSA B149.1 and local

applicable codes), or ducted directly to the boiler.

Ventilation air must be provided in either case.

2.13.1 Air From Room

Standard requirements for providing air for

combustion and ventilation are provided by ANSI

Z223.1/NFPA 54 and in Canada by CSA B149.1.

These codes require passages be provided for air flow

into the space where the boiler is installed. The size of

these passages is based on the firing rate of the boiler

and the path of air flow into the space. In general,

installations which take air from inside the building

require larger passages than those which take air

directly through an outside wall.

Failure to provide adequate combustion and

ventilation air can cause the boiler, and other

appliances occupying the same space, to operate with

dangerous and inefficient combustion, and can cause

overheating of the space. Be sure to provide air

passages in accordance with ANSI Z223.1/NFPA 54,

in Canada, CSA B149.1 and local applicable codes,

and do not permit any other condition, such as an

exhaust blower, to affect the air supply for combustion

and ventilation.

2.13.2 Ducted Combustion Air

Combustion air can be brought directly to the

boiler through a duct of suitable size and length (see

Table 7). Consult Laars about installations not covered

by Table 7.

Combustion air must be taken from out-of-doors

by means of the Laars side wall terminal.

Locate the terminal within 10 feet (3.0m) of the boiler

vent exhaust terminal, but no closer than 3 feet (0.9m)

(centerline distance).

Do not locate the air inlet terminal near a source

of corrosive chemical fumes (e.g., cleaning fluid,

chlorine compounds, etc.). Locate it so that it will not

be subject to damage by accident or vandalism. It must

be at least 7 feet (2.1m) above a public walkway.

Use single-wall galvanized pipe for the

combustion air duct. Route the duct to the heater as

directly as possible. Seal all joints with tape. Provide

adequate hangers. The heater must not support the

weight of the combustion air duct.

When combustion air is ducted to the boiler,

other provisions must be made for boiler room

ventilation. HH boilers lose less than 1 percent of their

input rating to the room, but other heat sources may be

present. Provide enough ventilation air to meet

comfort specifications. Make sure the ventilation air is

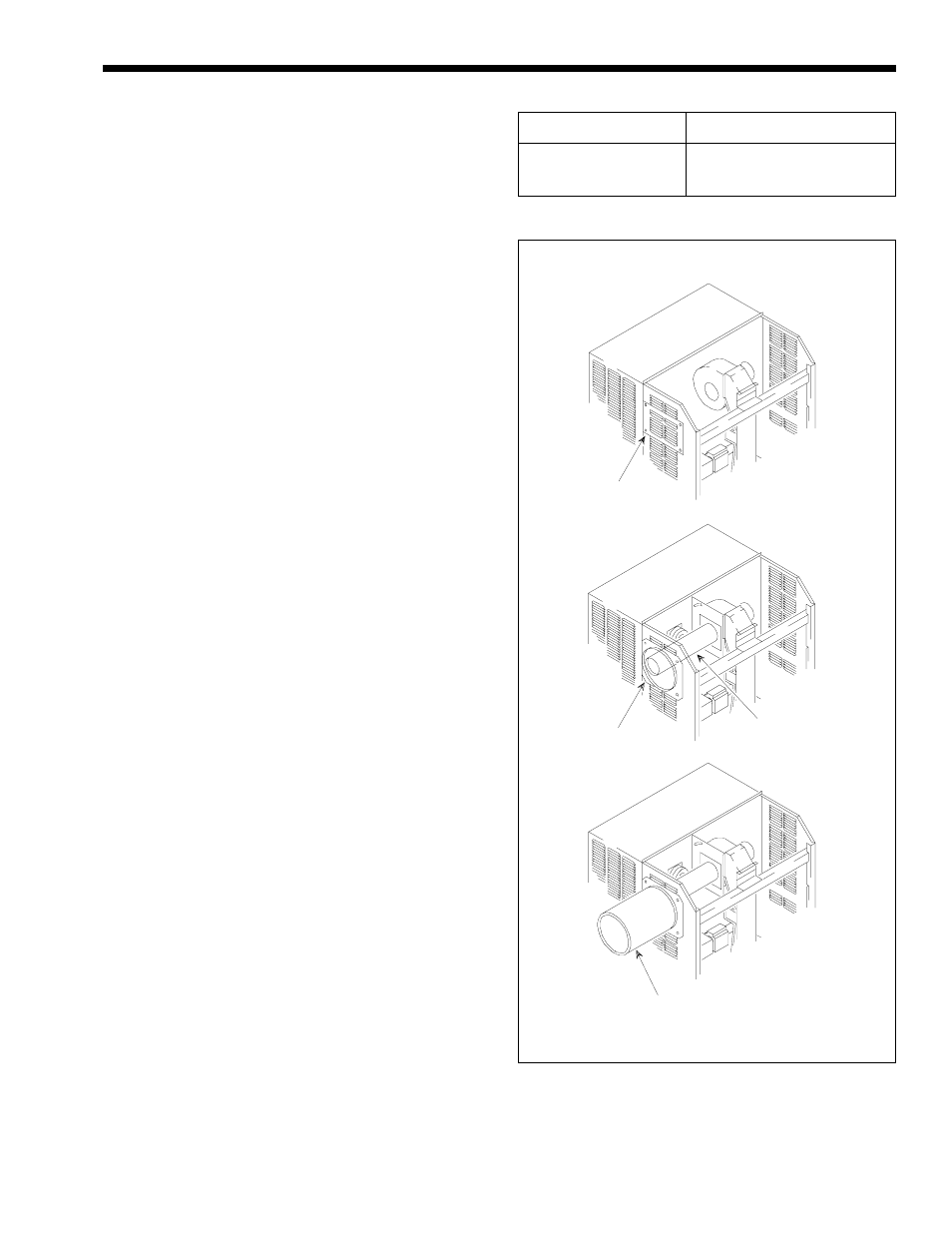

Figure 11. Ducted Combustion Air Conversion.

Ducted Combustion

Air Pipe

Inlet

Pipe

Adapter

Plate

Louvered

Plate

Boiler Size

Assembly Number

320

20258101

400

20258102

Table 8. Combustion Air Assembly.

not directed at the boiler, water piping or other

equipment which could be damaged by freezing.

OUT OF

PRODUCTION