Out of production – LAARS Mighty Max HH (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 8

Page 8

LAARS Heating Systems

2.7.2 Variable Water Flow Systems

There can be reduced water flow through the

boiler in heating systems using zone valves, zone

pumps or 3-way valves. This can result in a high

temperature rise across the boiler. Laars recommends

primary-secondary pumping for all variable flow

systems. The boiler pump in a primary-secondary

system maintains constant flow through the boiler

even though the system flow is variable. In a primary-

secondary system the pressure drop of the boiler is not

added to the system (see Figure 5).

2.7.3 System Pressure Requirements

The Model HH boilers are designed to operate

on closed, pressurized systems. Maintain a minimum

of 12 psi (81.8 kPa) on the system where boiler supply

water temperature is 200°F (93°C) or less. If higher

temperatures are required, the minimum system

pressure should be at least 15 psi (102.2 kPa) above

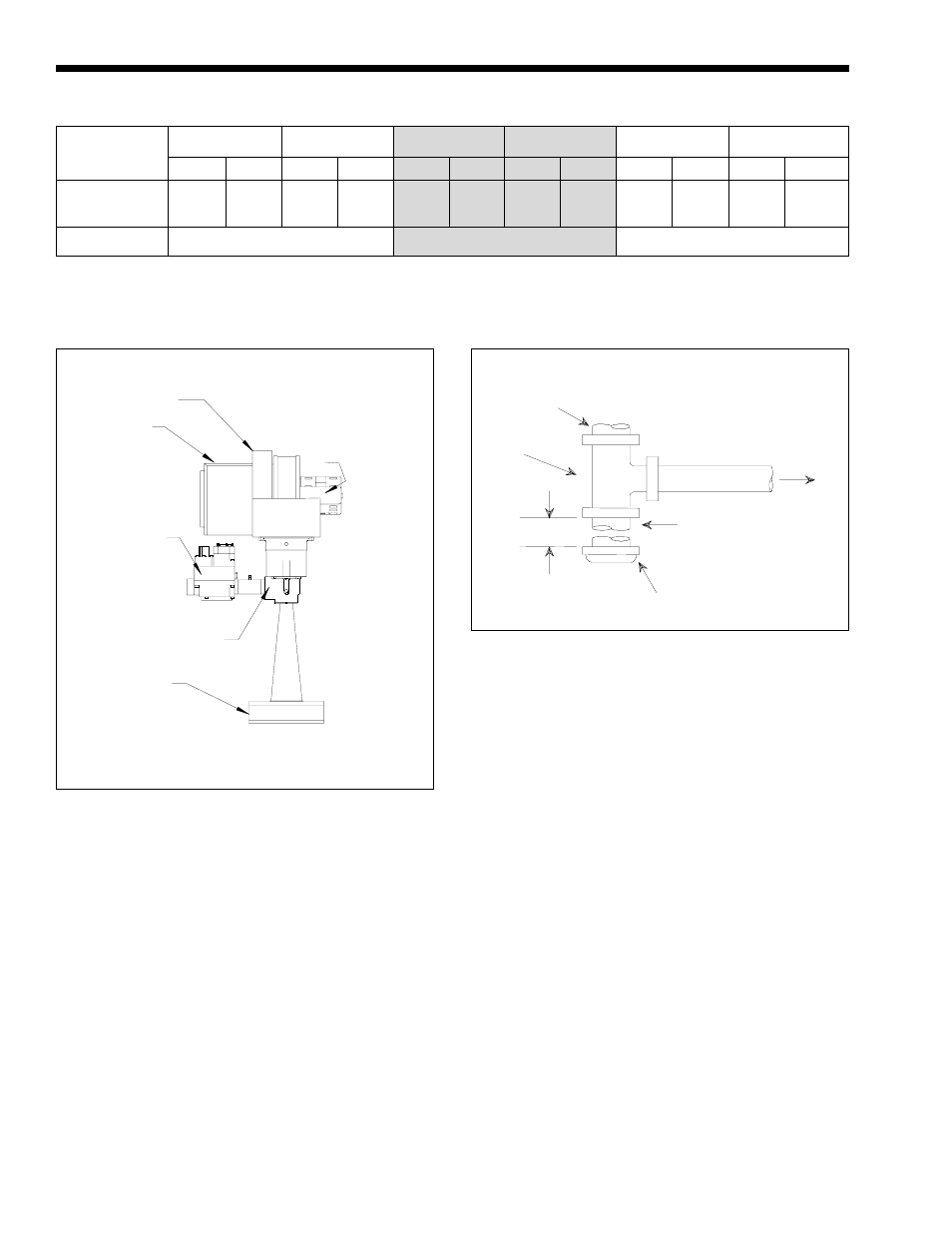

Figure 4. T-Fitting Sediment Trap Installation.

Gas Supply

Inlet

Tee

Fitting

3 In.

(76mm) Min.

Cap

Nipple

To Equipment

Inlet

Figure 3. Boiler Gas Valve Arrangement.

Note: The above diagram is a representation. Actual

venturi assembly may vary depending on boiler size.

Venturi

Air Shutter

Enclosure

Automatic,

Regulator

and

Redundant

Gas Valve

Mixture

Plenum

Filter

Housing

Blower

Motor

the water vapor pressure corresponding to the elevated

water temperature.

The Model HH boilers are not suitable for open

systems unless the supply water temperatures are

kept below 180°F (82°C), and a minimum of 5 psi

(34.1 kPa) static head is maintained at the boiler.

2.7.4 Hot/Chilled Water Systems

When a boiler is connected to an air conditioning

system where the same water is used for heating and

cooling, you must prevent chilled water from entering

the boiler. When changing such a system from cooling

to heating, allow the chilled water to circulate through

the building, after the chiller has been turned off, for a

period long enough for the water to warm up to at

least 105°F (41°C) before the water flows into the

boiler. It is equally important to prevent hot water

from entering the chiller. The system shown in Figure

6 is suggested to make sure the system water is neither

too hot nor too cold when a changeover takes place.

When a boiler is connected to heating coils located in

air handling units (where they may be exposed to

refrigerated air circulation), install a flow control

valve or other automatic means to prevent gravity

circulation of chilled water through the boiler. Chilled

water in the boiler will create condensate on the boiler

NOTES: Sizes 320M and 400M use 4-pass heat exchangers.

*Pressure drop (head loss) through the boiler, expressed in ft. of H

2

O.

Shaded area is the recommended flow and temperature rise. Minimum inlet temperature is 120°F (49°C).

Table 5. Temperature Rise.

TEMPERATURE RISE IN DEGREES (°F / °C )

MODEL

10°F

6°C

15°F

8°C

20°F

11°C

GPM

H/L ft.

LPS

H/L m

GPM

H/L ft.

LPS

H/L m

GPM

H/L ft.

LPS

H/L m

HH0320M

54

11.2

3.41

3.4

36

5.0

2.27

1.5

27

2.8

1.70

0.9

HH0400M

68

26.2

4.29

8.0

45

11.5

2.84

3.5

34

6.6

2.15

2.0

Flow

High

Normal

Low

OUT OF

PRODUCTION