Out of production – LAARS Mighty Max HH (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 21

Mighty Max Hydronic Boiler

Page 21

and the venturi pressure switch tubes are in place and

firmly connected.

The field checkout involves measuring gas and

venturi pressures, and observing the flame through the

sight glass. If necessary, the gas input rate can be

measured by timing the gas meter.

Install shutoff valves at the gas orifice (regulator

outlet) tap (red), at the venturi inlet tap and at the gas

plenum tap. Do not remove any of the plastic fittings

or plastic tubing. After installing the shutoff valves, be

certain they are closed.

a. Unfired Venturi Differential Pressure -

Natural Gas

NOTE: Turn off the main manual gas valve.

The difference in pressure between the venturi

inlet tap and the gas plenum tap (see Figure 15). This

measurement is taken by connecting the positive side

of the manometer to the venturi inlet tap and

connecting the negative side of the manometer to the

gas plenum tap. This measurement is taken with the

boiler not firing. It is a temporary setting used to start

the boiler and check for air flow problems.

b. Gas Offset Pressure - Natural Gas

The difference in pressure between the venturi

inlet tap and the outlet of the gas regulator (see

Figure 16). This measurement is taken by connecting

the positive side of the manometer to the venturi inlet

tap and connecting the negative side of the manometer

to the gas orifice tap. This measurement is an

indication of the gas to air ratio and must be

performed while the unit is firing.

c. Gas Orifice Differential Pressure -

Natural Gas

This measurement is the pressure drop across the

gas orifice. This measurement is taken by connecting

the positive side of the manometer to the gas orifice

tap and the negative side of the manometer to the gas

plenum tap (see Figure 17). This measurement in

conjunction with the gas orifice size is an indication of

the gas firing rate and must be performed while the

unit is firing.

By setting the gas offset pressure and gas orifice

differential pressure according to Table 10, the correct

input rate and gas to air ratio is achieved.

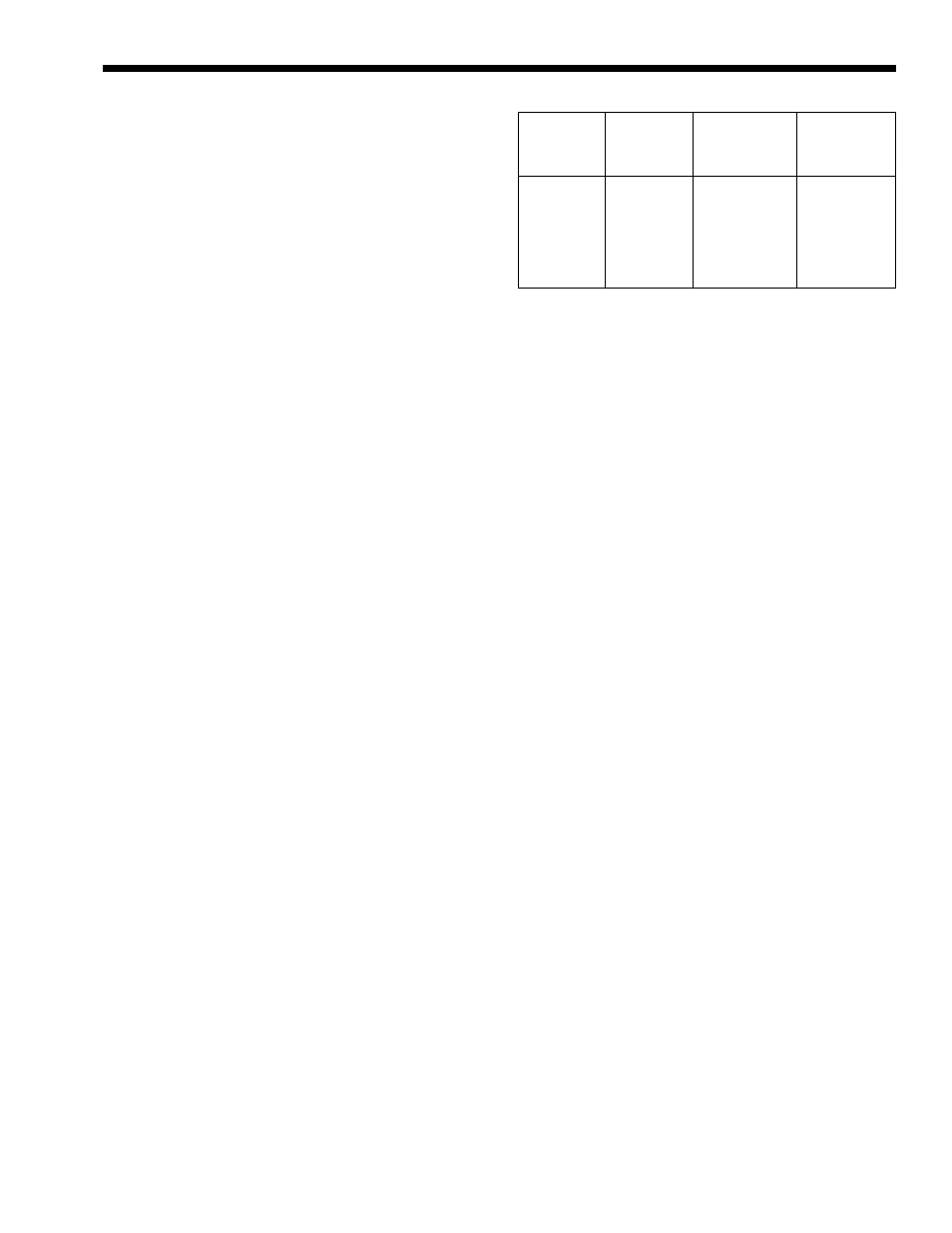

GAS

GAS ORIFICE

UNFIRED

ELEVATION,

OFFSET

DIFFERENTIAL

VENTURI

FT

PRESSURE

PRESSURE

DIFFERENTIAL

inch W.C.

inch W.C.

inch W.C.

SEA LEVEL

+0.4

+4.0

+5.8

2000

+0.4

+3.7

+5.3

4000

+0.4

+3.4

+4.9

6000

+0.4

+3.2

+4.6

8000

+0.4

+2.9

+4.2

10000

+0.4

+2.7

+3.9

Table 10. Venturi Pressure Settings - Natural Gas.

3.6.3 Venturi Setup Procedure -

Natural Gas

1.

Loosen the nut on the blower shutter to allow for

adjustment. Turn the heater on so that the blower

is running and the heater is not firing. Measure

the unfired venturi differential pressure. In this

unfired condition, adjust the shutter until the

unfired venturi differential pressure is according

to Table 10, “Unfired Venturi Differential” (5.8

± .3 inches wc at sea level). If this pressure range

can not be achieved, check for blockage in the

combustion air inlet, boiler and venting system.

If there is no obvious cause contact a qualified

Laars service technician.

2.

Approximately 40 seconds after the blower starts

the gas valves will open. The heater is now

firing. If the heater is not running, check all

manual gas valves and heater safety devices.

Ensure proper gas supply pressures according to

Table 4 in Section 2.

3.

Measure the gas offset pressure. Using the

regulator only, adjust the gas offset pressure

according to the installation’s altitude in Table 10

(+0.4 inches wc. at sea level). REPLACE THE

REGULATOR CAP BEFORE TAKING GAS

PRESSURE READINGS. Turn the regulator

screw clockwise to decrease the gas offset

pressure, turn the regulator screw

counterclockwise to increase the offset.

4.

Using the toggle switch, turn the heater off. Turn

the heater back on and check the gas offset

pressure while the heater is firing. If the gas

offset pressure is not according to Table 10,

adjust the regulator as needed.

5.

Measure the gas orifice differential pressure.

This pressure must be adjusted according to

Table 10 (4.0 ± .2 inches wc at sea level). Use

the blower shutter to adjust the gas orifice

differential.

6.

By adjusting the gas orifice differential, the gas

offset pressure will change. Therefore you must

repeat steps 3-5 until the gas offset and gas

orifice differential pressures are according to

Table 10.

OUT OF

PRODUCTION