Out of production – LAARS Mighty Max HH (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 10

Page 10

LAARS Heating Systems

Install a correctly sized expansion or

compression tank with suitable air charger and

tank drainer, as appropriate.

5.

Support the weight of all water and gas piping by

suitable hangers or floor stands.

6.

Check piping diagrams with local applicable

plumbing, heating and building safety codes.

2.9 Filling The System

1.

Ensure the system is fully connected. Close all

bleeding devices and open make-up water valve.

Allow system to fill slowly.

2.

If make-up water pump is employed, adjust

pressure switch on pumping system to provide a

minimum of 12 psi (81.8 kPa) at the highest

point in the heating loop.

3.

If a water pressure regulator is provided on the

make-up water line, adjust the pressure regulator

to provide at least 12 psi (81.8 kPa) at the

highest point in the heating loop.

4.

Open bleeding devices on all radiation units at

the high points in the piping throughout the

system, unless automatic air bleeders are

provided at such points.

5.

Run system circulating pump for a minimum of

30 minutes with the boiler shut off.

6.

Open all strainers in the circulating system,

check flow switch operation, and check for

debris.

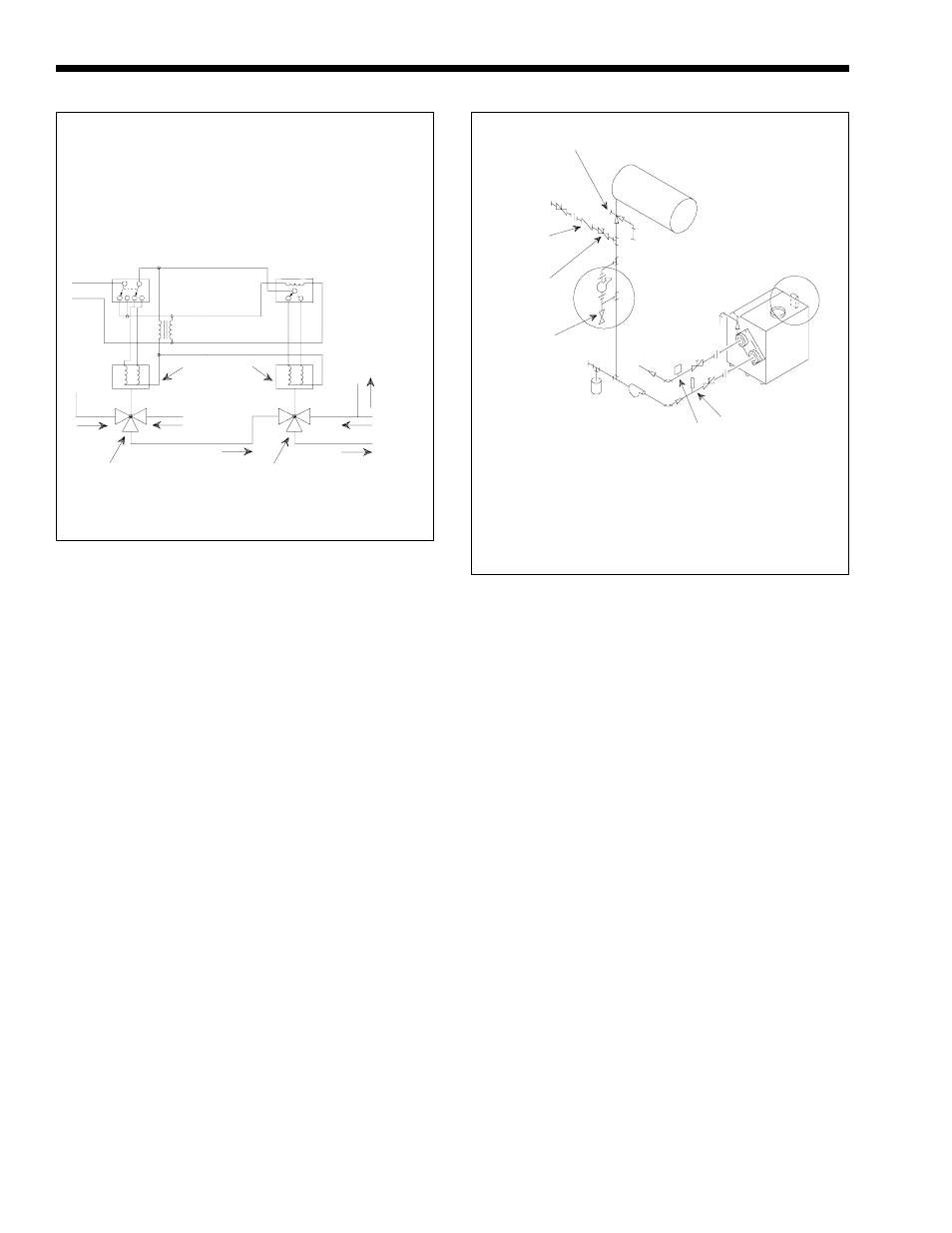

3-Way Valve No. 1

Change-Over

(Heating and Cooling)

3-Way Valve No. 2

To By-Pass

Both Heater and

Chiller

To

System

From

System

By-Pass

To Boiler

and

Chiller

From

Boiler

Valve Motors

2-Pos

3-Wire - 24V

115/24V

Transformer

DPDT Manual or Automatic

Change-Over Switch

DPDT - Set at Change-Over

Temperature

Clock Timer

Auto-Resetting

Set at 15 Minute SPDT

Suggested Wiring Diagram For

Tempering System Water at

Changeover From Heating To Cooling

Figure 6. Boiler-Chiller Installation.

From

Chiller

7.

Recheck all air bleeders as described in Step 4

above.

8.

Check liquid level in expansion tank. With the

system full of water and under normal operating

pressure, the level of water in the expansion tank

should not exceed 1/4 of the total, with the

balance filled with air.

9.

Start up boiler according to procedure described

in Section 3.1. Operate the entire system,

including the pump, boiler, and radiation units

for one (1) hour.

10. Recheck the water level in the expansion tank. If

the water level exceeds 1/4 of the volume of the

expansion tank, open the tank drainer and drain

to that level.

11. Shut down the entire system and vent all

radiation units and high points in the system

piping as described in Step 4 above.

12. Close make-up water valve and check strainer in

pressure reducing valve for sediment or debris

from the make-up water line. Reopen make-up

water valve.

13. Check gauge for correct water pressure and also

check water level in the system. If the height

indicated above the boiler insures that water is at

the highest point in the circulating loop, then the

system is ready for operation.

Make-Up

Water

Supply

Check

Valve

Pressure

Reducing

Valve

Blow Down

Valve

Expansion

Tank

To Drain

Method 1

To

Drain

Method 2

To

System

Strainer

Pump

Thermometer

Temperature

and Pressure

Gauge

NOTES: Select Method 1 or 2 when using low water cutoff accessory:

1. Under Method 1, the low water cutoff is furnished by Laars and

shipped as a separate item for fieldinstallation.

2. Under Method 2, electronic low water cutoff isinstalled, wired and

tested on boiler in Laars factory.

3. Preferred locaiton of system pump is shown. Compression tank must

always be on suction side of pump.

Figure 7. Boiler Piping.

Air Changer

and Tank

Drainer

OUT OF

PRODUCTION