Out of production – LAARS Mighty Max HH (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 13

Mighty Max Hydronic Boiler

Page 13

IMPORTANT: Maximum pipe length allowed is 50 feet (15m), regardless of the number of elbows. Maximum number of elbows allowed is 5.

Vent pipe minimum clearance from combustible surfaces is 6 inches (152mm).

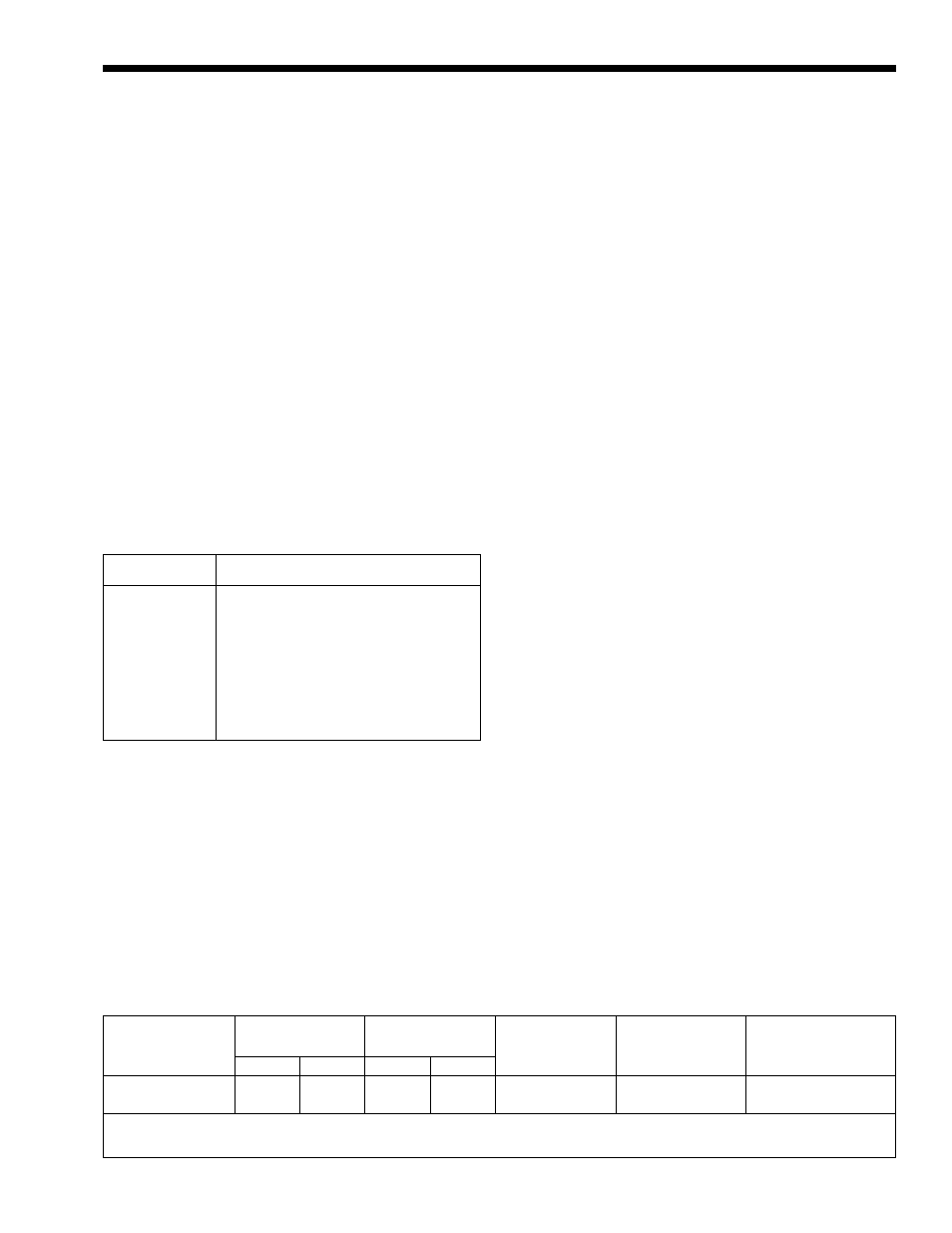

Table 7. Vent Piping Specifications (Combustion Air Exhaust).

1.

Remove the adapter plate from the top panel.

2.

On the boiler jacket, remove the top panel and

ease its lip from under the edge of the bonnet to

gain access to the flue collector.

3.

Remove the vent collar/stack from the flue

collector. Do not damage the vent collar/stack

during removal.

4.

Remove the blank plate from the rear of the

jacket.

5.

Remove the blank plate from the rear section of

the flue collector. Be careful not to lose the

insulation attached to the plate.

6.

Apply high temperature sealant and install the

blank plate (previously removed from the rear

section of the flue collector) on top of the flue

collector.

7.

Install the blank plate (previously removed from

the rear of the boiler jacket) over the stack

opening on the top panel of the boiler.

8.

Apply high temperature sealant (see Table 6) to

vent collar/stack and install on the rear of the

flue collector.

Term

Description

Pipe

Must comply with UL Standard 1738

such as type 29-4C stainless steel

Joint Sealing

Follow vent manufacturer's

instructions

Insulation

Recommended, but not required,

minimum R5 with protective cover

Table 6. Required Horizontal Venting Material.

9.

Slip the adapter plate over the vent collar/stack

and install it onto the rear boiler jacket (see

Figure 9).

2.12Venting

Venting must be in accordance with these

instructions and applicable requirements of the latest

edition of ANSI Z223.1/NFPA 54. In Canada,

installation must be in accordance with the latest

edition of CSA B149.1, and applicable local codes.

2.12.1 Vertical Venting - Category I

The Mighty Max boiler has a fan-assisted

combustion system, so vertical vents must be installed

in accordance with the special code requirements for

Category I - Fan-Assisted Appliances. These

requirements can be found in the latest edition of

ANSI Z223.1/NFPA 54, Appendix G, Table 1, and in

Canada, CSA B149.1, Amendment No. 1. These codes

permit installation as a single appliance or in

combination with other Category I appliances.

However, there are very important requirements for

minimum and maximum vent diameter and length.

Make sure vertically-vented installations comply with

these codes.

NOTE: If a vent cannot be installed in accordance

with the requirements of these codes, it must be

installed as a horizontal vent, even if it is mainly

vertical.

2.12.2 Vertical Venting - Non-Category I

When venting does not meet the code

requirements for Category I - Fan-Assisted Vertical

Vents, it can develop positive pressure. Such venting

must be installed in accordance with this section or

Section 2.12.3.

The following requirements must be used for

Non-Category I venting:

1.

Laars specified vent pipe material (Table 6) and

sizes (Table 7).

2.

Pipe insulation and sealing tape.

3.

Routing vent pipe through spaces which, except

for the terminal, remain above 60°F (16°C)

during heater operation.

2.12.3 Horizontal Venting - Non-Category I

When venting is horizontal, or cannot meet the

code requirements for Category I - Fan-Assisted

Vertical Vents, it can develop positive pressure and

must be installed in accordance with this section.

The following requirements must be used for

Horizontal Venting - Non-Category I:

1.

Laars specified vent pipe material (Table 6) and

sizes (Table 7).

2.

Laars side wall vent hood.

3.

Pipe insulation and sealing tape.

Heater

Pipe Diameter

Max Pipe Length

Max No.

Side Wall

Side Wall

Size

of Elbows

Vent Terminal

Combustion Air

in.

mm

in.

mm

Part Number

Terminal Part Number

320M

6

152

50

15

5

D2004500

20260701

400M

7

178

50

15

5

D2004600

20260702

OUT OF

PRODUCTION