Out of production – LAARS Mighty Max HH (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 28

Page 28

LAARS Heating Systems

4.

Use the troubleshooting flow chart (see Figure

20) to determine what components and wiring

should be tested first.

5.

Test each component by checking for 24 Vac or

120 Vac entering and exiting the device. If there

is voltage entering the safety device, but none

leaving then there is an open circuit and it must

be determined why it is open. When testing

components between “MV1” of the ignition

control and the gas valve install a meter and let

the heater cycle through one complete sequence

of operation. During the sequence of operation

these safeties will only be energized for the

seven second trial for ignition.

6.

Turn the manual gas valve on the boiler on and

fire the boiler.

SECTION 6.

Parts List for Mighty Max HH Boiler

6.1 General Information

To order or purchase parts for the Laars Mighty

Max HH boiler, contact your nearest Laars contractor

or distributor. If they cannot supply you with what

you need, contact:

Laars Customer Service Department

6000 Condor Drive

Moorpark, California 93021

Telephone (805) 529-2000

Telephone

(800) 900-9276

In Canada, contact:

Laars Customer Service Department

480 S. Service Road West

Oakville, Ontario, Canada L6K 2H4

Telephone (905) 844-8233.

Item Description

Part Number

1.

Base Assembly

320M ........................................................... 20157801

400M ........................................................... 20157802

2.

Burner and Burner Plenum Weldment

320M ........................................................... 20268401

400M ........................................................... 20268402

3.

Venturi Assembly

320M ........................................................... 20158601

400M ........................................................... 20158602

4.

Combustion Chamber Weldment

320M ........................................................... 20159101

400M ........................................................... 20159102

5.

Gas Train Assembly

320M ........................................................... 20254901

400M ........................................................... 20254902

Gas Valve

320M, 400M ................................................ V2003900

Orifice Holder

320M, 400M ................................................ P2017500

6.

Motor, Blower

320M thru 400M Nat. & Prop. Gas ............. A2088100

7.

Electrical Controls

High limit Control ........................................... E0015900

Toggle Switch ................................................. E0109200

Indicator Light ................................................ E0071300

Fusible Link ................................................... E0099403

Transformer ................................................... E0086100

Fuse Holder ................................................... E2000300

Fuse, 2 Amp .................................................. E2043600

Flow Switch .................................................... E0013000

Burner Temperature Switch ........................... E2076100

Low Water Cutoff ........................................... E2075100

Pump Time Delay .......................................... E2077700

8.

Sight Glass .................................................... F0044800

9.

Igniter, Hot Surface ....................................... W0038001

10. Gasket, Igniter Hot Surface ........................... 20409800

11. Control, Remote Ignition ................................ E2101300

12. Control, Temperature ..................................... E2101400

13. Display, Temperature ..................................... E2101600

15. Heat Exchanger Assy., 4 pass, Copper Tubes

320M ........................................................... 20259601

400M ........................................................... 20259602

Heat Exchanger Assy., 4 pass, Cupronickel tubes

320M ........................................................... 20104701

400M ........................................................... 20104702

16. Cover, Machined In/Out ................................. 20150200

17. Plate, Mach. Adapter

320M, 400M ................................................ 20150302

18. Flange, Machined

320M, 400M ................................................ 20255400

19. Cover, Machined Rear ................................... 20150100

20. Pressure Switch, Differential 320-775 ........... E0115200

Pressure Switch, Differential 1000 ................. E0161400

21. Flue Collector Assembly (with gaskets)

320M ........................................................... 20155401

400M ........................................................... 20155402

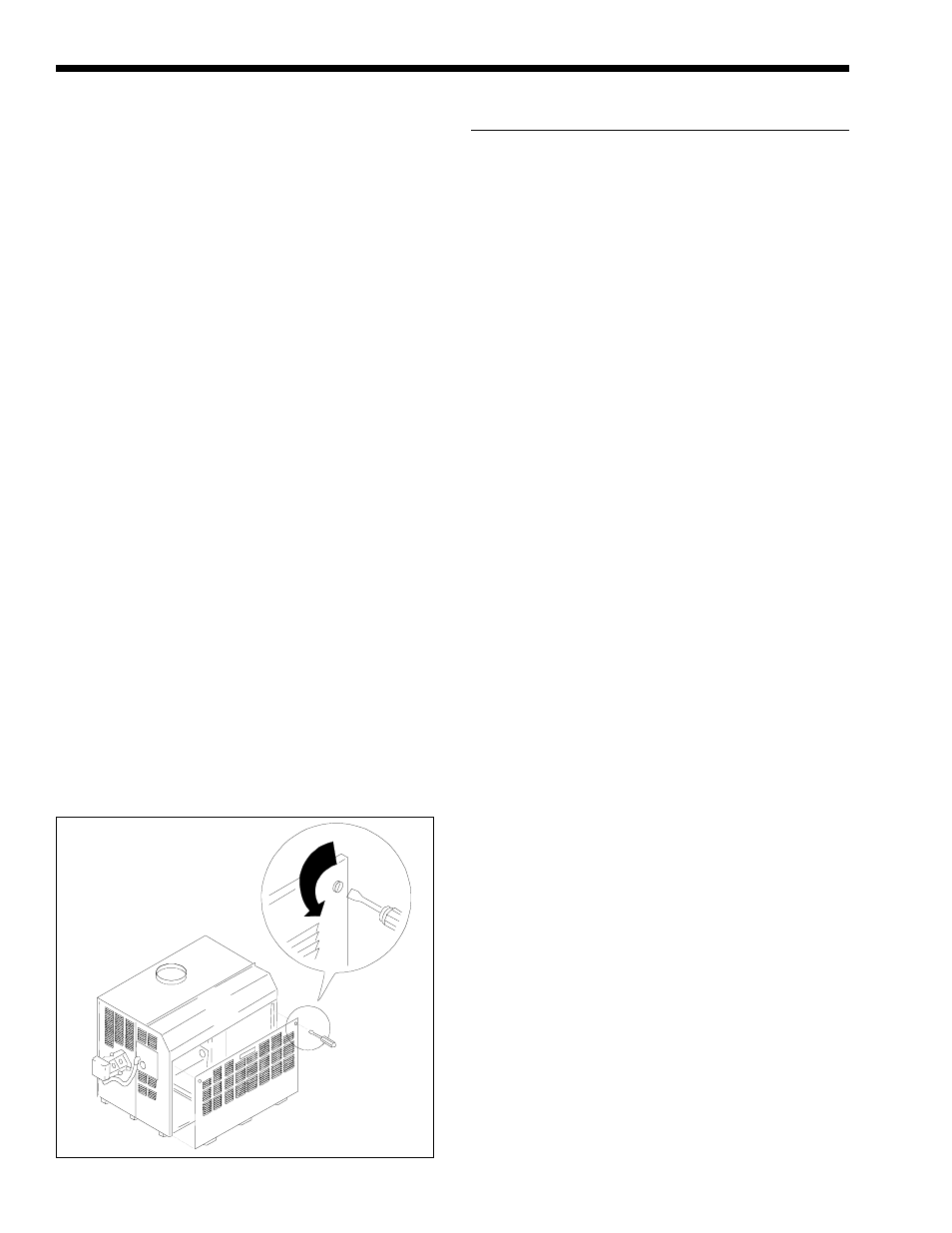

Figure 21. Lower Front Panel Removal.

OUT OF

PRODUCTION