Out of production – LAARS Mighty Max HH (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 22

Page 22

LAARS Heating Systems

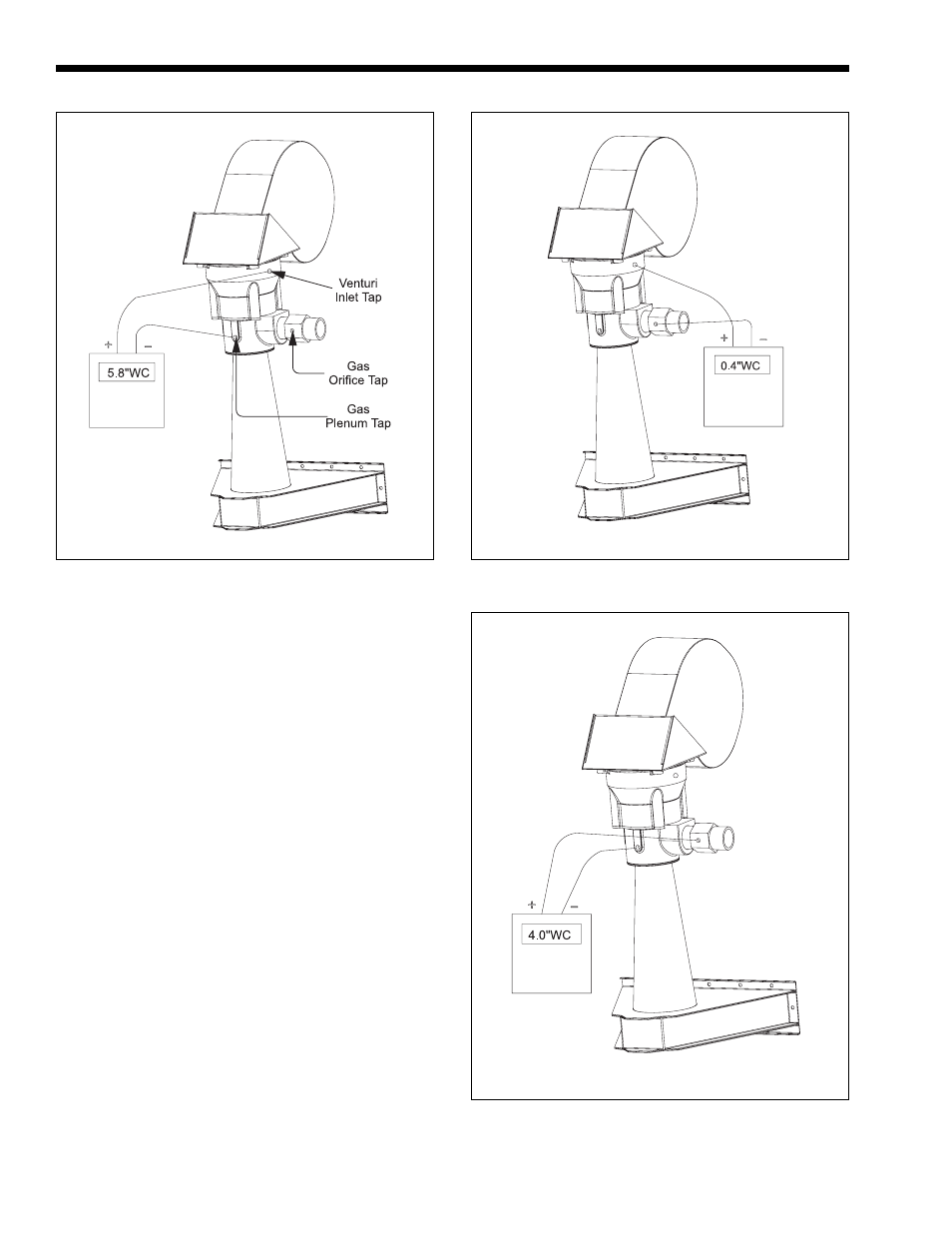

Figure 16. Gas Offset Pressure - Natural Gas.

Figure 17. Gas Orifice Differential Pressure - Natural Gas.

Figure 15. Unfired Venturi Differential Pressure - Natural

Gas.

7.

After setting all pressures, turn the heater off and

replace each shutoff valve with the factory

installed threaded plugs. The venturi has now

been adjusted for proper operation.

3.7 Venturi Adjustment - Propane Gas

The field checkout involves measuring gas and

venturi pressures, and observing the flame through the

sight glass. If necessary, the gas input rate can be

measured by timing the gas meter.

Use a single, inclined manometer or digital

manometer with a 4.0 inch water column range. Install

shutoff valves at the gas orifice (regulator outlet) tap

(red), at the venturi inlet tap (blue) and at the venturi

throat tap (yellow). After installing the shutoff valves,

be certain they are closed (see Figure 18).

1.

With the heater off, connect the positive side of

the manometer to the shutoff valve on the venturi

inlet tap (blue). Open the shutoff valve.

2.

Loosen the nut on the blower damper to allow

for adjustment. Turn the boiler on so that the

blower is running and the boiler is not firing. In

this unfired condition, adjust the damper until the

venturi inlet pressure (blue tap) is 1.2 inches

water column.

3.

Approximately 40 seconds after the blower starts

the gas valves will open. The boiler is now

firing. If the heater is not running, check all

manual gas valves and heater safety devices.

OUT OF

PRODUCTION