Troubleshooting, Page 31 laars sequencing controls s8 & s8ext – LAARS S8Ext - Installation Manual User Manual

Page 31

Page 31

LAARS Sequencing Controls S8 & S8EXT

TROUBLESHOOTING

TEMPERATURE INPUTS

Display shows Sensor OPEN

Check the sensor is connected and the wires are continuous to the S8. Finally follow the

procedure for Incorrect Temperature Display.

Display shows Sensor SHORT

The S8 sees a short across the input terminals. Remove the wires from the sensor terminals.

The display should change to read OPEN. If it doesn’t, the S8 may be damaged.

Display shows an Incorrect Temperature Display

Remove the wires from sensor terminals. The display should change to read OPEN. If it

doesn’t, the S8 may be damaged. Take an ohm reading across the detached sensor wires. The

ohm reading should correspond to the side chart. If it doesn’t, the sensor may be damaged.

Return Sensor does not Display Temperature

Check the sensor is connected and the wires are continuous to the S8. Finally follow the

procedure for Incorrect temperature display.

CONTROL OPERATION

Too Much Heat

Check if the control has any of the following:

• Domestic Hot Water call - The S8 will raise the temperature of the system to either 200˚F or

Maximum Target on a DHW call.

• Reset Ratio and Offset - If excessive heat occurs only in certain weather conditions, adjust

the Reset Ratio and Offset (See Understanding Operating Concept). If excessive heat occurs

year round, reduce the Offset.

• Unit Mode Settings - The S8 will only sequence boilers their mode is set to Auto or Standby.

Check to see if any boiler stage is set to On.

• Control Settings - The Last Stage Hold will allow only the Lead boiler to stay on for an

additional number of degrees. If the setting is too high, and only the Lead boiler is on, the

system can over heat. Reduce the Last Stage Hold setting.

Too Little Heat

Check if the control has any of the following:

• Reset Ratio and Offset - If reduced heat occurs only in certain weather conditions, adjust the

Reset Ratio and Offset (See Understanding Operating Concept). If reduced heat occurs year

round, increase the Offset.

• Setback and Day/Night Schedule - If reduced heat occurs only during specific hours, check

the Day/Night Schedule and the Setback, Boost, and Boost Period values. Either reduce the

Setback or Boost settings or change the Day and Night Schedules.

• Boiler Mode Settings - The S8 will only modulate boilers their mode is set to Auto or

Standby. Check if any boiler stage is set to Off or Standby.

Units are Short-Cycling

• Minimum Runtime - Increase the Minimum Runtime only if all units tend to short-cycle.

• Last Stage Hold - Increase the Last Stage Hold only if the lead unit tends to short-cycle.

System is Overshooting or Undershooting

• Reaction Time and Minimum Runtime - If the system is overshooting or undershooting, adjust Minimum Runtime or the

Reaction Time. That depends on if the stages are brought on fast and were not allowed to turn off until the Minimum Runtime

elapsed. Or, the stages were brought on slowly, however, were allowed to turn off quickly.

• PID vs OSS - If the application the system is used on requires fast response that the normal PID mode cannot provide, try using

the OSS mode and adjust its parameters according to the system requirements.

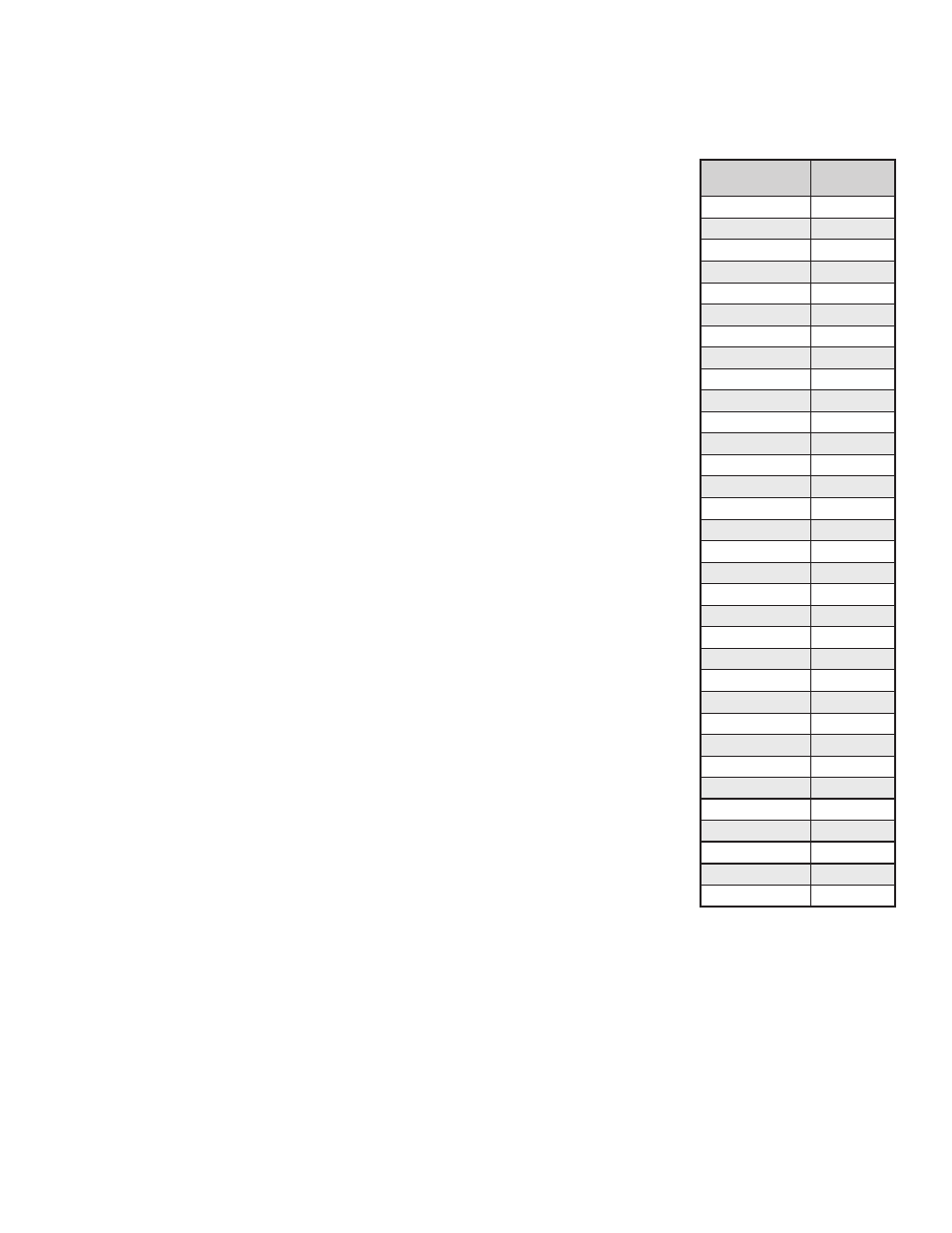

Temperature Sensor Chart

TEMPERATURE

(in Degrees °F)

Value

(in Ohms)

-30

117720

-20

82823

-10

59076

0

42683

10

31215

20

23089

25

19939

30

17264

35

14985

40

13040

45

11374

50

9944

55

8714

60

7653

70

5941

80

4649

90

3667

100

2914

110

2332

120

1879

130

1524

140

1243

150

1021

160

842

170

699

180

583

190

489

200

412

210

349

220

297

230

253

240

217

250

187