S8ext a, S8ext b, S8ext – LAARS S8Ext - Installation Manual User Manual

Page 16: Xsig, 20 ma ems, Startup settings, Caution, F od, F de gh jk hi lo -- off, Op power

Page 16

LAARS Heating Systems

STARTUP SETTINGS

PROGRAM CHANGE SETTINGS

To be able to change the S8 settings the Program/Run Switch must be set to Program. The

switch is located under the Enclosure Wiring Cover for security. The Enclosure Wiring Cover

can be securely closed using a padlock.

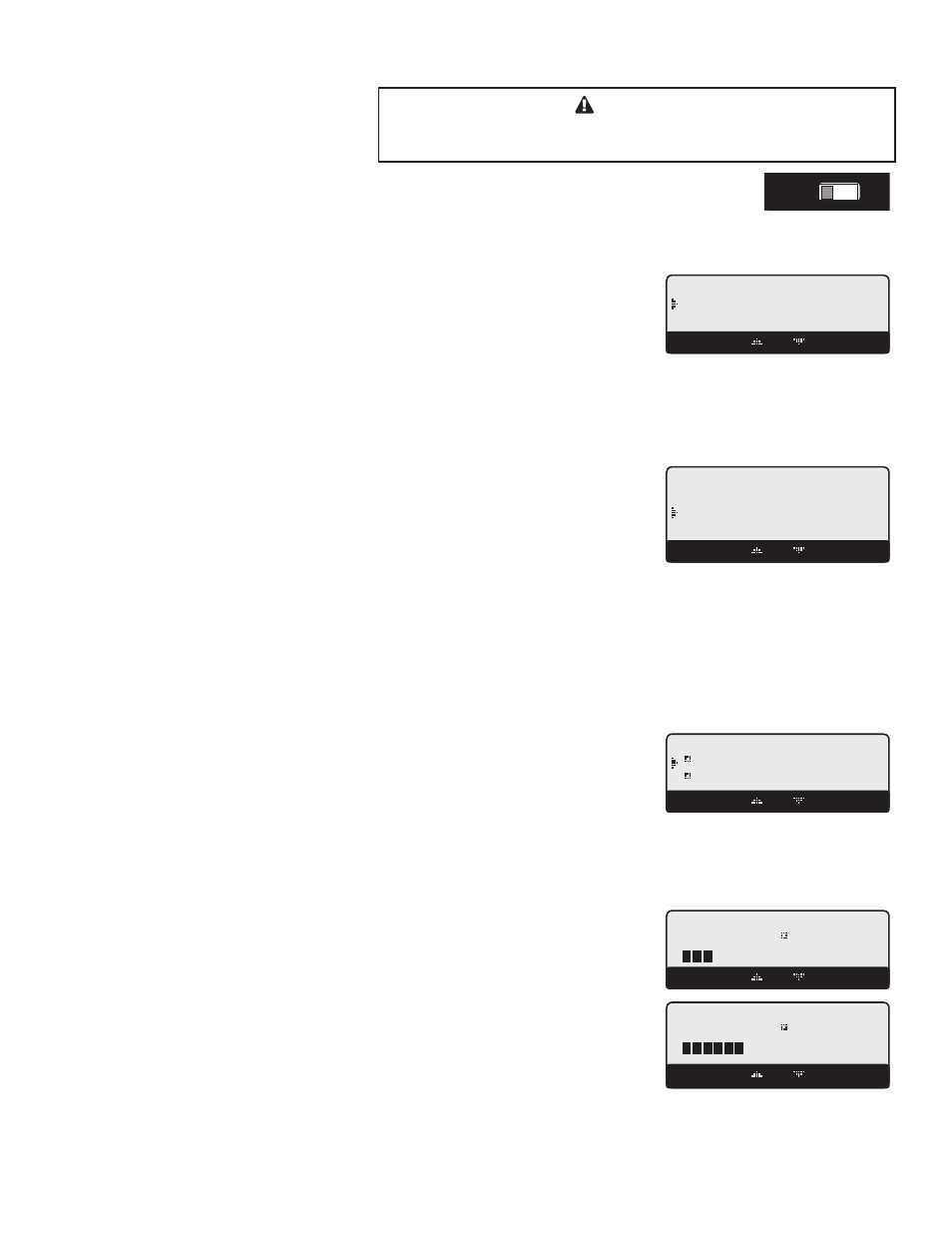

Connecting S8 to Two Extension Panels

and XSIG Interface using RS485

S8

SYSTEM

DHW PUMP

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

Use Copper Conductors Only.

CAUTION:

Risk of Electric Shock.

PWR

L N

1 2

SENSORS MUST BE GOLD SERIES

SYSTEM

3

DHW

PUMP

5

Stage A

7

Stage B

9

Stage C

11

13

Stage E

15

Stage F

17

Stage D

6

8

10

12

14

16

18

RS485

SYS=

144

F OD=

35

F

GH

JK

HI LO -- OFF

4

Stage G

19

Stage H

21

OUTDOOR

TEMP

27

29

31

DHW

33

SHUTDOWN

/SETBACK

35

RETURN

TEMP

20

22

28

30

32

34

36

STAGE

MENU

Stage E

Stage F

Stage G

Stage H

Stage A

Stage B

Stage C

Stage D

25

26

PRESS

+ -

37

38

PROVE

SYSTEM

TEMP

PROGRAM

RUN

23 24

COMB.

AIR

DO NOT APPLY ANY VOLTAGE TO INPUT TERMINALS

COMB. AIR

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

C

US

O

P

Power

CAUTION:

Risk of Electric Shock.

PWR

L N

1 2

I

3 4

J

5 6

K

7 8

L

9 10

M

11 12

EXTENSION

MODULE

RS-485

Ext A

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

Ext B

L

M

N

Comm

T

U

V

W

X

N

13 14

Q

S

U

R

T

V

S8EXT A

Use Copper Conductors Only.

I

J

K

Q

R

S

O

15 16

P

17 18

W

X

O

P

Power

CAUTION:

Risk of Electric Shock.

PWR

L N

1 2

I

3 4

J

5 6

K

7 8

L

9 10

M

11 12

EXTENSION

MODULE

RS-485

Ext A

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

Ext B

L

M

N

Comm

T

U

V

W

X

N

13 14

Q

S

U

R

T

V

S8EXT B

Use Copper Conductors Only.

I

J

K

Q

R

S

O

15 16

P

17 18

W

X

4-20 mA EMS

4-20mA INPUT

+

Signal GND

1

2

3

RS485

EXTENSION

CONNECTORS

XSIG 4-20mA EMS Interface

4-20mA

EMS Signal

(+)

(-)

6 Pin Phone Cable (provided with Extension)

6 Pin Phone Cable (provided with XSIG Interface)

S8

SEQUENCING CONTROL

S8EXT

SEQUENCING CONTROL

XSIG

STARTUP SEQUENCE

Button: MENU/

• When powered, the S8 performs a self-test on its components. After the self-test

diagnostics have been successfully completed, the S8 will initialize the panel.

• On the first power up, the System Startup screen will appear after the initialization is

complete. If it doesn’t, the S8 has already been configured.

ARE YOU SURE?

No

Yes

BACK SAVE

• The System Startup menu sets the main parameters like the type of sensor, the type of output whether heating or cooling, the

sequencing mode, and many other parameters described in this section.

• Before entering the Startup menu, several warnings will alert you about the consequences of making Startup changes.

CONTROL MODE

Outdoor Reset, Set Point, EMS 4-20mA

Default: Set Point

Button: MENU/

• Outdoor Reset provides a variable set point based on outdoor temperature. Available for

Heating applications only.

• Outdoor Reset mode requires the use of an outdoor sensor. DO NOT select Reset without

an outdoor sensor.

---- CONTROL MODE ---

Outdoor Reset

Set Point

EMS 4-20mA

BACK SAVE

• Set Point mode does not require an outdoor sensor. If an outdoor sensor is connected in Set Point mode it will be used only as

an outdoor cutoff point. That is, to turn the stages, system, and Comb. Air relays off.

• The EMS 4-20mA allows the S8 to receive an external set point from an EMS/BMS system. This option requires the use of the

XSIG Interface (CA004200).

• You must select the 4mA (min) and 20 mA (max) Set Points in the following screens.

• Connect the XSIG Interface to the S8's RS485 connection.

DISPLAY UNIT

ºF, ºC

Default:ºF

Button: MENU/

• The S8 is designed to control boilers and chillers in hydronic environment where the

temperature is the critical factor. It allows the user of displaying temperature information

and settings in either ºF (Fahrenheit) or ºC (Celsius). Select the display unit that is best

suited for your application.

---- DISPLAY UNIT ---

F

C

BACK SAVE

SETTING THE 4MA AND 20MA SET POINTS (AVAILABLE IN 4-20MA EMS ONLY)

Default: Normal

Button: MENU/

• If EMS 4-20mA is selected from the Control Mode Menu as the temperature set point

source, the user must purchase a Laars XSIG Interface (CA004200) to accept the 4-

20mA signal and transmit it to the S8.

EMS 4mA SET POINT

100 F

[

]

BACK SAVE

• In addition, the user will need to set the temperature range parameters. First, set the 4mA

temperature, then the 20mA temperature.

• Any signal that is above or below the 4-20mA range will display the message

"Shutdown by EMS" and all stages will de-energize. However, the System,

Comb. Air, and Unit Pumps and Valves will continue for the Run-On delay period then

de-energize.

• The control will calculate the temperature for the additional 1.9mA at each end of 4

- 20mA range.

EMS 20mA SET POINT

170 F

[

]

BACK SAVE

CAUTION

A good practice after performing any Startup menu modifications is to

check all operating settings and adjustments to match the new settings.