3 measuring principle, 4 configuration, 5 operating conditions – KERN & SOHN TN 60-0.01EE User Manual

Page 4

4

TN_EE-BA-e-1410

1.3 Measuring Principle

The digital ultrasonic thickness gauge determines the thickness of a part or structure

by accurately measuring the time required for a short ultrasonic pulse generated by a

transducer to travel through the thickness of the material, reflect from the back or in-

side surface, and be returned to the transducer. The measured two-way transit time

is divided by two to account for the down-and-back travel path, and then multiplied by

the velocity of sound in the material. The result is expressed in the well-known

relationship:

2

t

v

H

×

=

Where: H-Thickness of the test piece.

v-Sound Velocity in the material.

t-The measured round-trip transit time.

1.4 Configuration

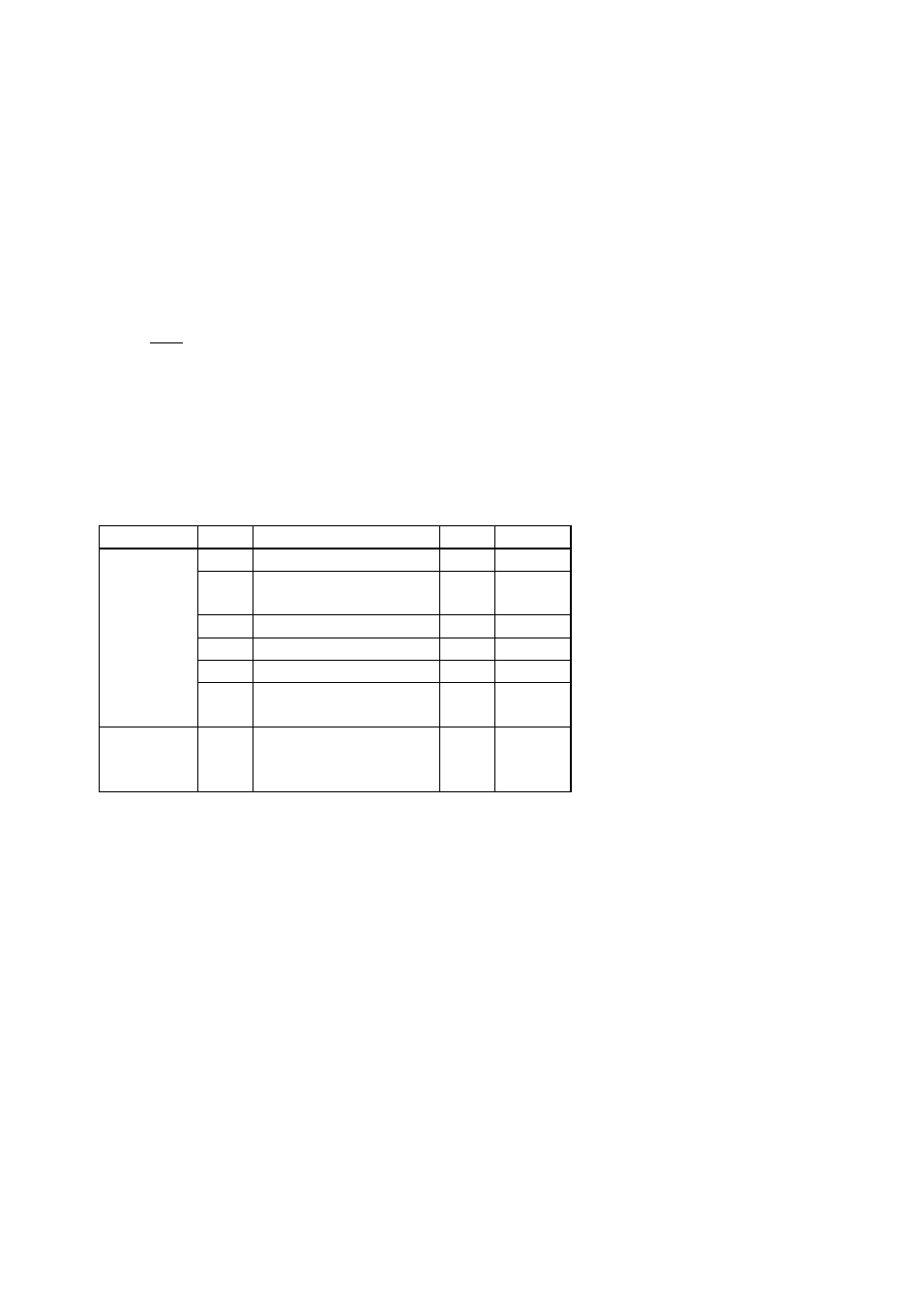

Table 1-1

No

Item

Qty. Note

Standard

Configu-

ration

1

Main body

1

2

Sensor P5EE,

10 MHz, Ø 10mm

1

3

Couplant

1

4

Transport Case

1

5

Instruction Manual

1

6

Alkaline battery

2

AA

size

Optional

Configu-

ration

11

Data Software

(ATU-04)

1

1.5 Operating Conditions

Operating Temperature: -20

℃~+60℃;

Storage Temperature:-30

℃~+70℃

Relative Humidity: ≤90%

In the environment of usage vibrations, strong magnetic field, corrosive medium and

heavy dust should be avoided.