Step 2 — provide unit support, Step 3 — provide clearances, Step 4 — place unit – Carrier 50ZH024-060 User Manual

Page 5: Step 5 — select and install ductwork

RECEIVING AND INSTALLATION

Step 1 — Check Equipment

IDENTIFY UNIT — The unit model number and serial num-

ber are stamped on the unit identification plate. Check this

information against shipping papers.

INSPECT SHIPMENT — Inspect for shipping damage while

unit is still on shipping pallet. If unit appears to be damaged

or is torn loose from its securing points, have it examined by

transportation inspectors before removal. Forward claim pa-

pers directly to transportation company. Manufacturer is not

responsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify

the nearest Carrier Air Conditioning office if any item is

missing.

To prevent loss or damage, leave all parts in original pack-

ages until installation.

Step 2 — Provide Unit Support

SLAB MOUNT — Place the unit on a rigid, level surface,

suitable to support the unit weight. The flat surface should

extend approximately 2-in. beyond the unit casing on the 2

outdoor coil sides. The duct connection side and condensate

drain connection sides should be flush with the edge of the

flat surface. A concrete pad or a suitable fiberglass mounting

pad is recommended.

A 6-in. wide gravel apron should be used around the flat

surface to prevent airflow blockage by grass or shrubs. Do

not secure the unit to the flat surface except where required

by local codes.

The unit should be level to within

1

⁄

4

inch. This is nec-

essary for the unit drain to function properly.

Step 3 — Provide Clearances —

The required mini-

mum service clearances and clearances to combustibles are

shown in Fig. 2-4. Adequate ventilation and outdoor air must

be provided.

The outdoor fan pulls air through the outdoor coil and dis-

charges it through the fan on the top cover. Be sure that the

fan discharge does not recirculate to the outdoor coil. Do not

locate the unit in either a corner or under an overhead ob-

struction. The minimum clearance under a partial overhang

(such as a normal house overhang) is 48 in. above the unit

top. The maximum horizontal extension of a partial over-

hang must not exceed 48 inches.

Do not restrict outdoor airflow. An air restriction at ei-

ther the outdoor-air inlet or the fan discharge can be harm-

ful to compressor life.

Do not place the unit where water, ice, or snow from

an overhang or roof will damage or flood the unit. The unit

may be installed on wood flooring or on Class A, B, or C

roof covering materials.

Step 4 — Place Unit —

Unit can be moved with the

handholds provided in the unit basepan. Refer to Table 1 for

operating weights. Use extreme caution to prevent damage

when moving the unit. Unit must remain in an upright po-

sition during all moving operations. The unit must be level

for proper condensate drainage; the ground-level pad must

be level before setting the unit in place. When a field-

fabricated support is used, be sure that the support is level

and that it properly supports the unit.

Step 5 — Select and Install Ductwork —

The de-

sign and installation of the duct system must be in accor-

dance with:

• the standards of the NFPA (National Fire Protection

Association) for installation of nonresidence-type air con-

ditioning and ventilating systems;

• NFPA 90A or residence-type, NFPA 90B; and/or local codes

and residence-type, NFPA 90B;

• and/or local codes and ordinances.

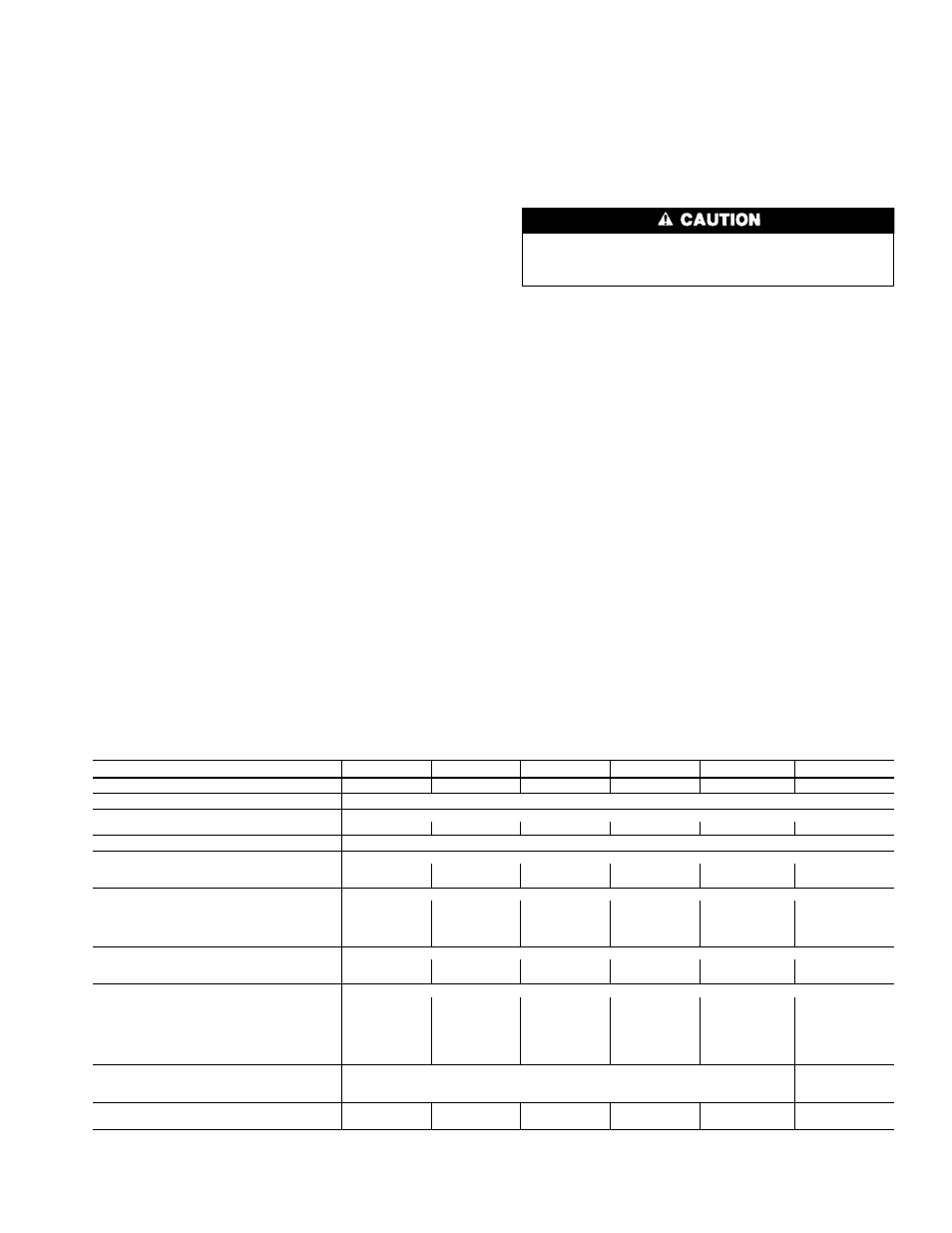

Table 1 — Physical Data

UNIT 50ZH

024

030

036

042

048

060

OPERATING WEIGHT (lb)

232

254

277

295

328

368

COMPRESSOR TYPE

Scroll

REFRIGERANT

R-22

Charge (lb)

4.0

5.8

5.9

9.2

10.9

11.0

REFRIGERANT METERING DEVICE

Acutrol™ System

OUTDOOR COIL

Copper Tubes, Aluminum Plate Fins

Rows...Fins/in.

1...17

2...17

1...17

2...17

2...17

2...17

Total Face Area (sq ft)

7.9

6.7

11.1

11.1

11.1

12.7

OUTDOOR-FAN MOTOR

Propeller

Nominal Cfm

1800

2000

2600

2600

2600

3200

Nominal Rpm

825

1100

1100

1100

1100

1100

Motor Hp

1

⁄

8

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

4

1

⁄

2

Diameter (in.)

20

20

20

20

20

20

INDOOR COIL

Copper Tubes, Aluminum Plate Fins

Rows...Fins/in.

2...15

3...15

3...15

3...15

4...15

4...15

Total Face Area (sq ft)

3.1

3.1

4.0

4.0

4.4

4.9

INDOOR-FAN MOTOR

Direct Drive

Blower Motor Size (in.)

10 x 8

10 x 8

10 x 9

10 x 9

10 x 9

10 × 10

Nominal Cfm

800

1000

1200

1400

1600

2000

Rpm Range

550-1000

550-1000

800-1050

800-1050

1000-1100

950-1100

Number of Speeds

3

3

3

3

2

3

Factory Speed Setting

Low

Med

Low

Med

Low

Low

Motor Hp

1

⁄

4

1

⁄

4

1

⁄

2

1

⁄

2

3

⁄

4

1

CONNECTING DUCT SIZES

Round

Square

Supply Air (in.)

14

13.9 × 13.9

Return Air (in.)

14

13.9 × 27.8

FIELD-SUPPLIED RETURN AIR FILTER*

Throwaway (in.)

24 x 24

24 x 24

24 x 24

24 x 24

24 x 30

24 × 30

*Required filter sizes shown are based on the ARI (Air Conditioning and Refrigeration Institute) rated airflow at a

velocity of 300 ft/min for throwaway type or 450 ft/min for high capacity type. Recommended filters are 1-in. thick.

5