Citizen Systems Citizen CLP 8301 CLP-8301 User Manual

Page 66

Chapter 7 Troubleshooting

−

52

−

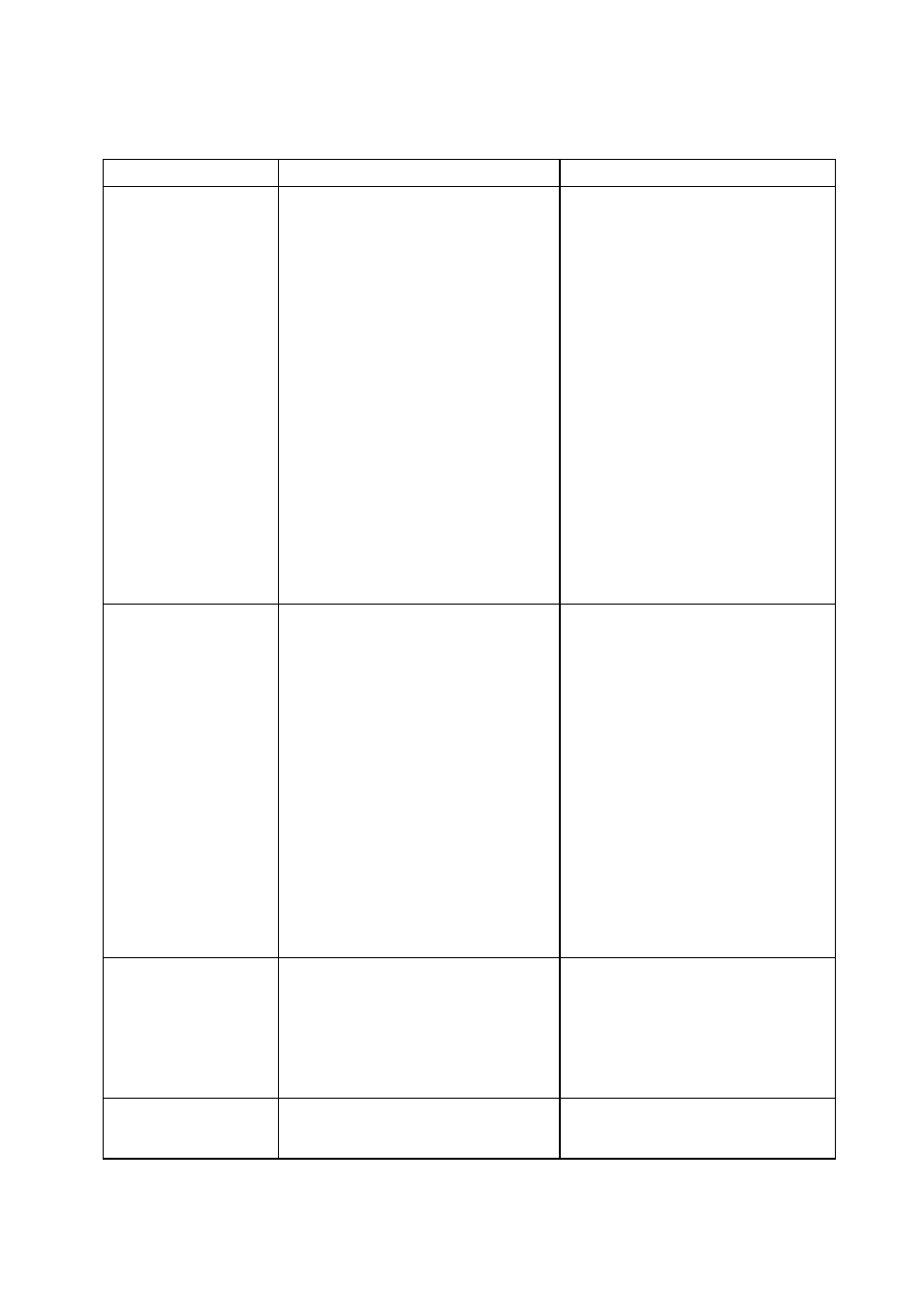

Symptom

Check

Remedy

Text is not printed

cleanly.

1. Is the media and ribbon loaded

properly?

2. Is the print density too dark or faint?

3. Is the platen dirty or deformed?

4. Is the printhead dirty? Is a label stuck?

5. Are you using a genuine CITIZEN

ribbon or its equivalent?

6. Is the printhead position proper for the

media being used?

1. Load the media and ribbon properly.

2. Set the proper print density via the

menu or control software.

3. If the platen is dirty, remove the dirt

using ethyl alcohol. If the platen is

deformed, contact our service

personnel for replacement.

4. If the printhead is dirty, wipe it off with

the head cleaning pen. If a label is

stuck, remove it.

CAUTION: Avoid using metallic tools

to remove labels stuck inside the

printer. (Metallic tools may damage

the printhead.)

If label adhesive material is stuck to

the printhead, wipe it off with ethyl

alcohol.

5. Use a genuine CITIZEN ribbon or i ts

equivalent.

6. Adjust the printhead position, using the

printhead adjustment lever.

Print position changes.

1. Is the media and ribbon loaded

properly?

2. Is the platen dirty or deformed?

3. Are you using a genuine CITIZEN

ribbon or its equivalent?

4. Are the contents of the data and signals

from the computer proper?

5. Are the values of the Menu set proper?

6. Is the media sensor level proper for the

media being used?

1. Load the media and ribbon properly.

2. If the platen is dirty, remove the dirt

using ethyl or isopropyl alcohol.

If the platen is deformed, contact our

service personnel for replacement.

3. Use a genuine CITIZEN ribbon or its

equivalent.

4. If a message of “ERROR RS-232C”

etc is displayed on the LCD, check the

contents of the software and the

communication conditions set on the

computer.

5. Set the proper values of the Menu set

from the control panel or your PC.

6. Incorrect sensor level may cause the

printer to miss some or all of the

end-of-label marks on the media.

Ribbon wrinkles.

1. Is the ribbon tension proper for the

media being used?

2. Is the ribbon guide plate guiding the

ribbon evenly?

3. Is the ribbon guide shaft guiding the

ribbon evenly?

1. Adjust the ribbon tension properly

(see P27).

2. Adjust the setting angle o f the ribbon

guide plate (see P31).

3. Adjust the setting angle of the ribbon

guide shaft (see P32).

Ribbon Smudge

1. Is the ribbon torque proper for the

media being used?

1. Adjust the ribbon torque properly

(see P27, 42, and 48).