Culligan Aqua-Cleer Advanced Drinking Water Systems User Manual

Page 9

9

. Repeat steps 1- and install the flushed activated carbon filter cartridge into housing

and the RO membrane element. Be sure the drain adapter is in place.

Note:

1) The RO cartridge must be

inserted into the 2nd, rd, or 4

th

position on the RO manifold.

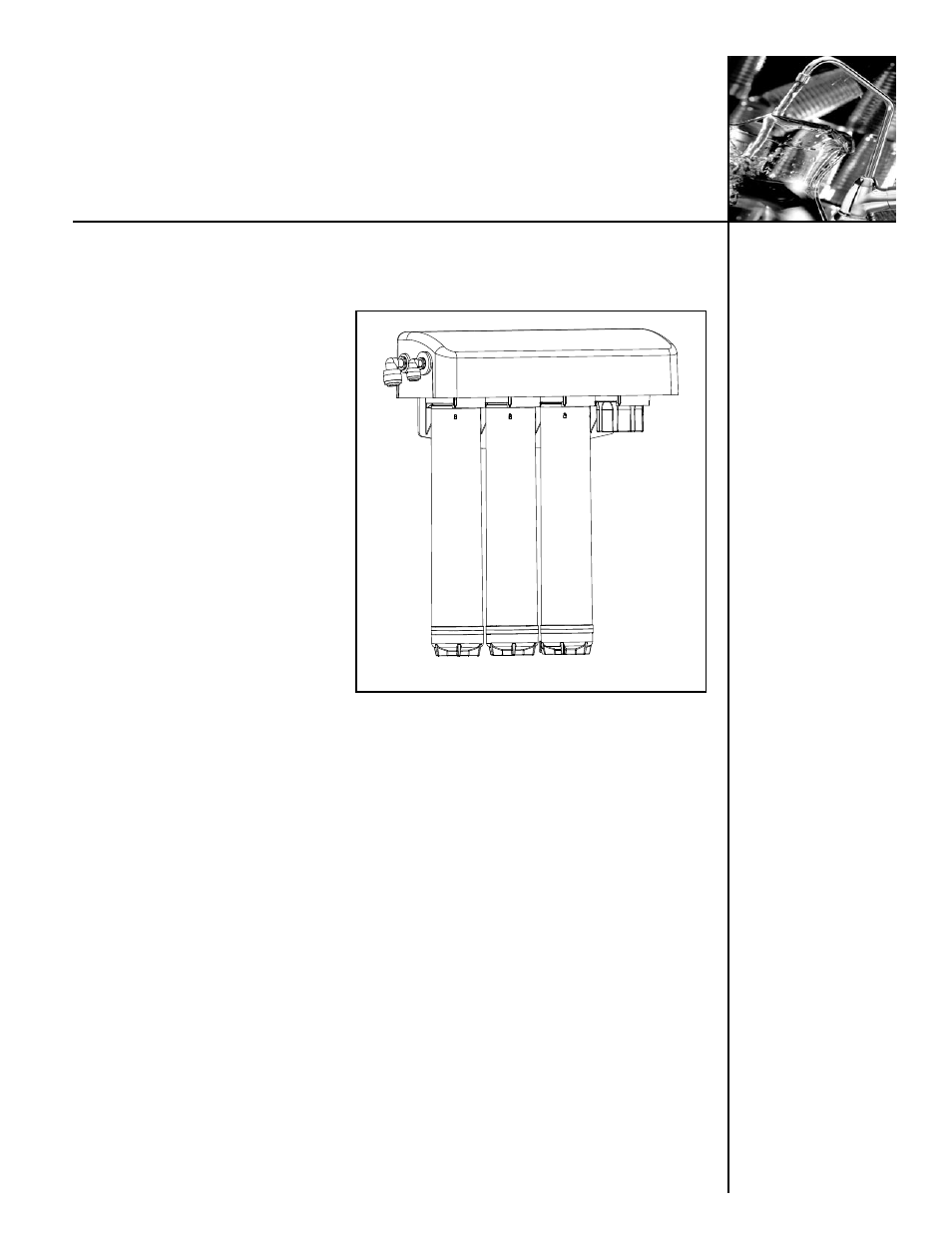

2) If only three cartridges are to

be inserted into the manifold, the

bypass plug cartridge must be

inserted in the 4th position. See

Figure .

Factors Which Affect

Performance

Performance of the reverse osmosis

membrane is affected by several

factors which must be considered

when judging the condition of the

system. The main factors which affect

system performance are pressure,

temperature, total dissolved solids

level, recovery and pH.

Pressure

Water pressure affects both the quantity and quality of the water produced by the RO

membrane. Generally, the more water pressure, the better the performance of the system.

Be careful not to exceed 120 psi, the maximum operating pressure of the Aqua-Cleer

system.

Temperature

The reverse osmosis process slows with decreasing temperature. To compensate,

a temperature correction factor is used to adjust the actual performance of the RO

membrane filter to the standard temperature of 77°F (25°C). This allows the performance

of the unit to be accurately gauged against Culligan’s published standards. Temperature

does not affect the concentrate flow rate.

Total Dissolved Solids

The minimum driving force which is necessary to stop or reverse the natural osmosis

process is termed osmotic pressure. As the total dissolved solids level of the feed water

increases, the amount of osmotic pressure increases and acts as back pressure against

the reverse osmosis process. Osmotic pressure becomes significant at TDS levels above

500 mg/L (ppm).

Hardness

Hardness is the most common membrane foulant. If ignored, this relatively harmless

Figure

Installation

(con’t)