Section 5 - troubleshooting – Intek RheoVac CMS User Manual

Page 35

September 2013

31

© Intek, Inc. 2013

Revision D

SECTION 5 - TROUBLESHOOTING

The CMS will identify problems by alternately flashing a message code and the serial number of

the instrument affected. Table 11 provides a guide to identify causes of problems and determine

appropriate actions to resolve the observed problems. If problems are encountered and factory assistance

is desired, please contact the factory.

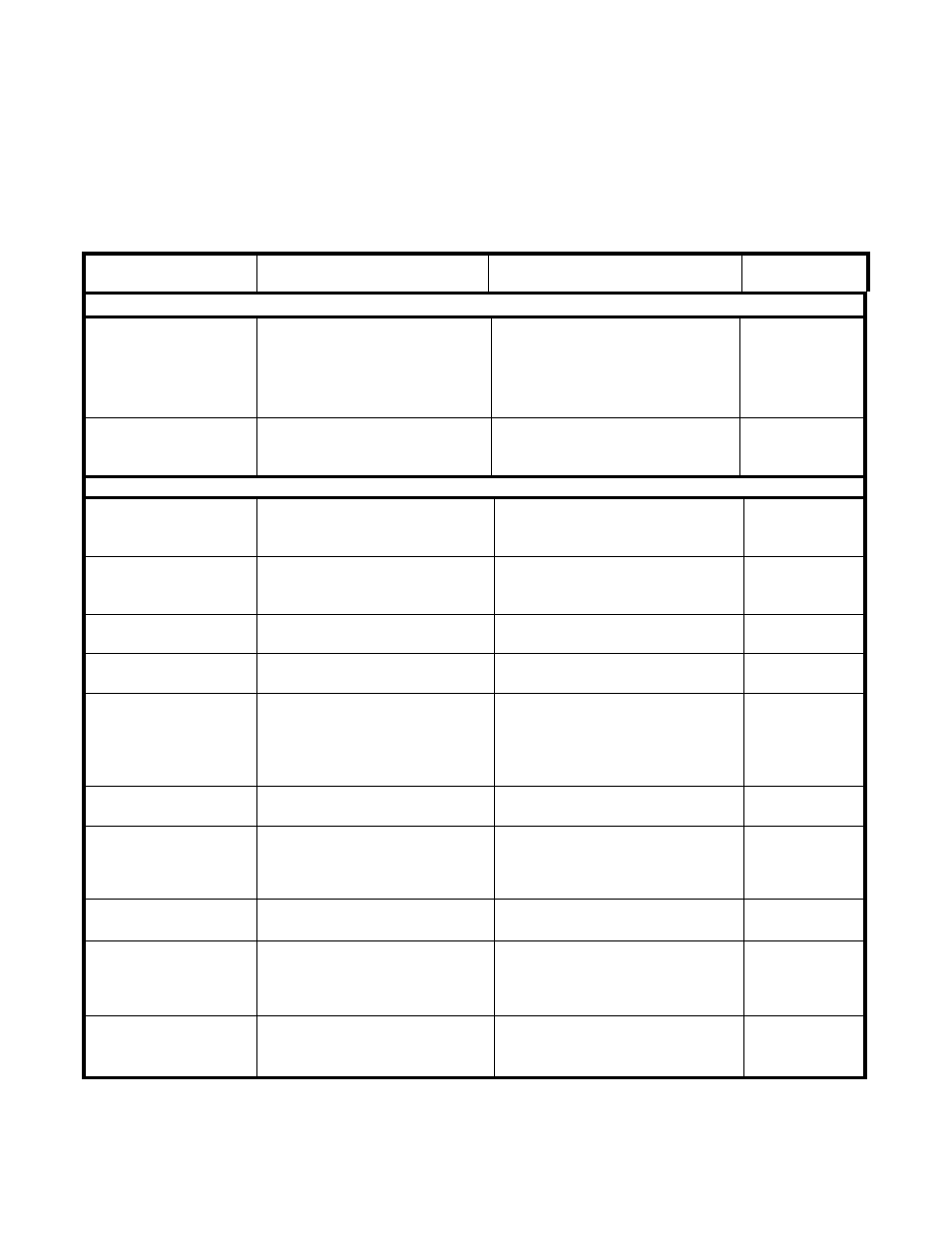

Table 11: Troubleshooting/message code guide (diagnostic messages)

MESSAGE CODE

Description/Symptom

PROBABLE CAUSE

ACTION

OUTPUT ERROR

CODES

Global Message Codes

MSG-0

Communications not

being received from

probe(s)

1. Improper cable hookup

2. Blown main fuse

3. Failed RS-485 circuit

4. Damaged flow sensor

1. Verify plug-in connector is

properly mated

2. Check F1 fuse on probe board

3. Check all cable connections

4. Contact factory

-99

MSG-1

Invalid data received

from probe(s)

1. Failed RS-485

communications component

1. Check wiring

2. Contact factory

N/A

RheoVac MSP Messages Codes

MSG-2

Flow sensor heater

“OFF”

1. Blown heater fuse

2. Failed electronic component

1. Contact factory

N/A

MSG-3

RS sensor power

“OFF”

1. Probe temperature too high

2. Liquid water on probe tips

1. Check that probe temperature is

<160°F

2. Contact factory

N/A

MSG-4

RS heater “OFF”

1. Component failure

1. Contact factory

N/A

MSG-5

Circuit issue

1. Problem with circuitry

1. Contact factory

N/A

MSG-6

Temperature alarm

(above 210°F/99°C)

1. Steam in exhaust pipe

1. Remove probe or cool line

ASAP!

2. Once line has cooled down and

probe is reinstalled, check unit

for proper function

N/A

MSG-7

Wet probe

1. Liquid water on probe tip

1. Remove probe ASAP!

2. Contact factory

N/A

MSG-8

RS sensor problem

1. RS sensor problem

1. Remove from line, allow 24 hrs

with power on to dry out RS

sensor, reinsert probe

2. Contact factory

N/A

MSG-9 or (CalX)

Calibration expired

1. Probe calibration is expired

1. Contact factory for recalibration

N/A

Mass flow output

saturates high, will not

respond to flow changes

1. Flow rate is not within range

of calibration

2. Blown heater fuse

3. Failed electronic component

1. Contact factory about re-ranging

instrument

2. Contact factory

N/A

Mass flow output

saturates low, will not

respond to flow changes

1. Flow rate is not within range

of calibration

2. Failed electronic component

1. Contact factory about re-ranging

instrument

2. Contact factory

N/A