Great Planes Patriot XL Kit - GPMA0450 User Manual

Page 37

❏

1. Reinstall the fuel tank, running the carb and vent lines out

of the holes in the firewall. Mark on the firewall with permanent

marker which line is vent and which line is carb (fuel).

❏

2. Connect the fuel lines to the carb and exhaust.

❏

3. Mount the landing gear to the fuselage.

❏

4. If you used pneumatic retracts, run all air tubing and

install the gear.

❏

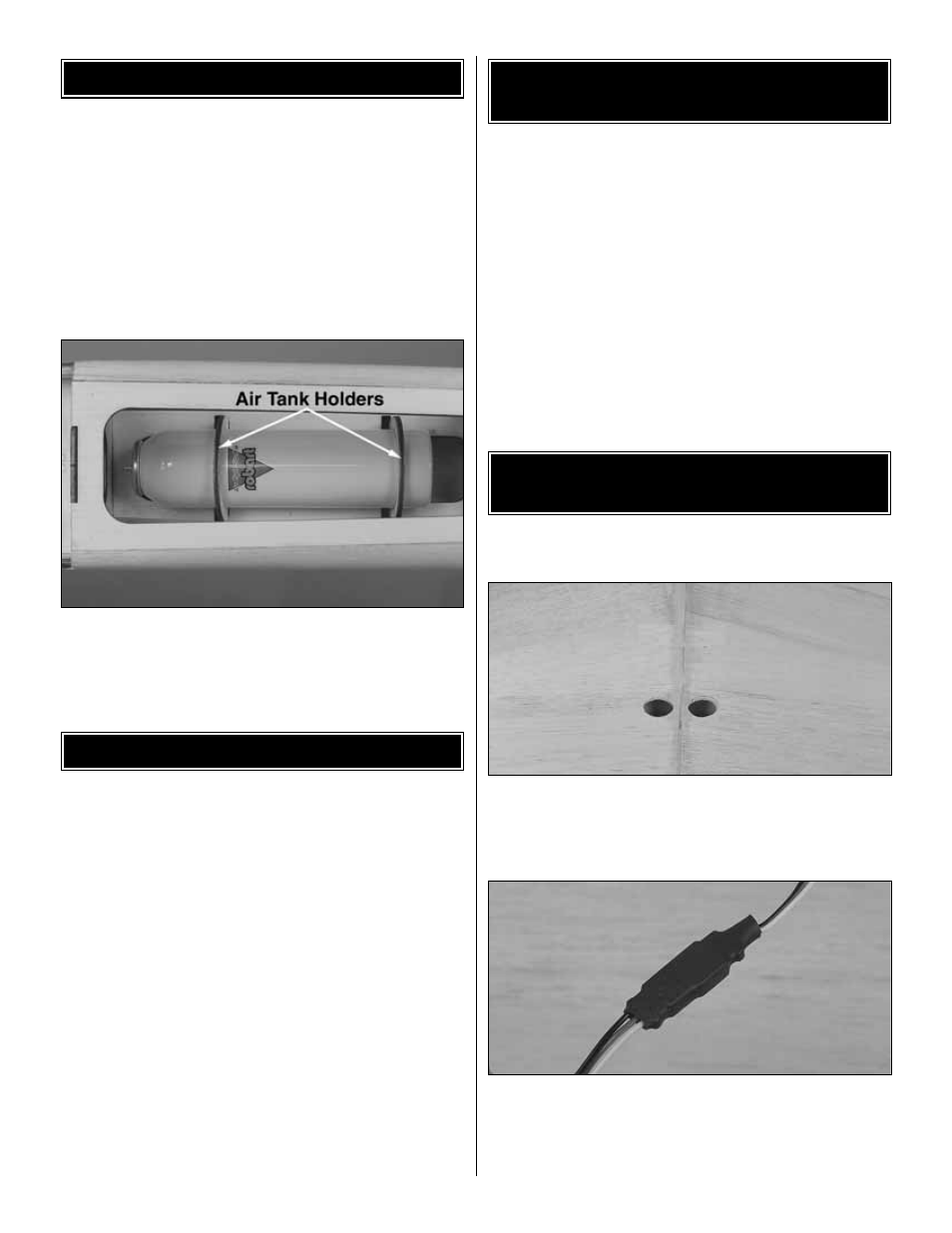

5. Install the air cylinder for your retracts as shown using

the 1/8" [3mm] air tank holders. Push the ends of the air tank

holders in the slots and slide forward into place.

Do not confuse this procedure with “checking the C.G.”, which

will be discussed later in the manual. A model which is not

laterally balanced may exhibit a variety of unpleasant traits,

ranging from uncharacteristic tip stalls to problems with spin

entries. This aircraft, when balanced properly, exhibits none of

these tendencies. Be sure to check the lateral balance

carefully as described to help ensure that the model exhibits

the same exceptional handling qualities as our prototypes.

❏

1. With the wing level, have an assistant help you lift the

model by the engine propeller shaft and the bottom of the

fuse under the TE of the fin. Do this several times.

❏

2. If one wing always drops when you lift the model, it

means that side is heavy. Balance the airplane by adding

weight to the other wing tip. An airplane that has been laterally

balanced will track better in loops and other maneuvers.

❏

1. Remove all the pushrods and control horns from the

ailerons, elevators, and rudder. Remove the engine, engine

mount and any other hardware you may have installed

❏

2. Most of the model should be rough-sanded by now, with

all the tabs and rough edges sanded even. Fill all dents, seams,

low spots, and notches with HobbyLite

™

Balsa Colored Filler.

❏

3. After the filler has dried, use progressively finer grades

of sandpaper to even all the edges and seams and smooth

all surfaces. Remove all balsa dust from the model with

compressed air, a vacuum with a brush, or a tack cloth.

❏

4. If you used retracts, install the air hoses and mount the

air cylinder as shown.

❏

1. Install all servos using the hardware supplied by your

radio manufacturer.

❏

2. Cut two 3/4" [19mm] holes in the wing to route the

servo leads. If you look inside the wheel well, you can see

the hole in R5 that the servo leads will exit, make the holes

in the wing just above the exit in R5.

❏

3. You will need to attach a 6" [150mm] servo extension

to the aileron servos PRIOR to routing the servo lead. After

you have the 6" [150mm] extension attached, cover the

connection with heat shrink tubing (GPMM1070) and seal

together as shown.

FINAL SERVO AND

RECEIVER INSTALLATION

PREPARE THE MODEL

FOR COVERING

BALANCE THE MODEL LATERALLY

INSTALL THE HARDWARE

37