Sheet the bottom of the wing – Great Planes Patriot XL Kit - GPMA0450 User Manual

Page 20

❏

3. Mix 1/4oz of 30-minute epoxy. Liberally coat the root rib

of one wing half, half of the wing joiner, and center web with

epoxy. Insert the joiner and clamp in place against the

center web (CW). Be sure there is plenty of epoxy coating

the wing joiner and center web; it should ooze out of

everywhere when the clamp is compressed.

❏

4. With one side of the joiner clamped in place, coat the

center web in the other wing half and the wing joiner. Twist

together the two wing halves.

❏

5. Clamp the wing joiner in place. Make sure the wing is

straight and the wing roots meet with little or no gap. Clean up

excess epoxy with a paper towel and denatured alcohol.

When the epoxy has fully cured, remove the clamps and fill in

any gaps with more epoxy.

❏

6. Cut a 2" x 6" [50 x 150mm] block from leftover 3/8"

[9.5mm] balsa from the wing tip blocks. This is the center

LE. Glue it to the LE center of the wing and shape it to

match the wing.

❏

7. Cut the shaped balsa bolt support to make two

supports. Trim each to match the plan and glue in place with

medium CA.

❏ ❏

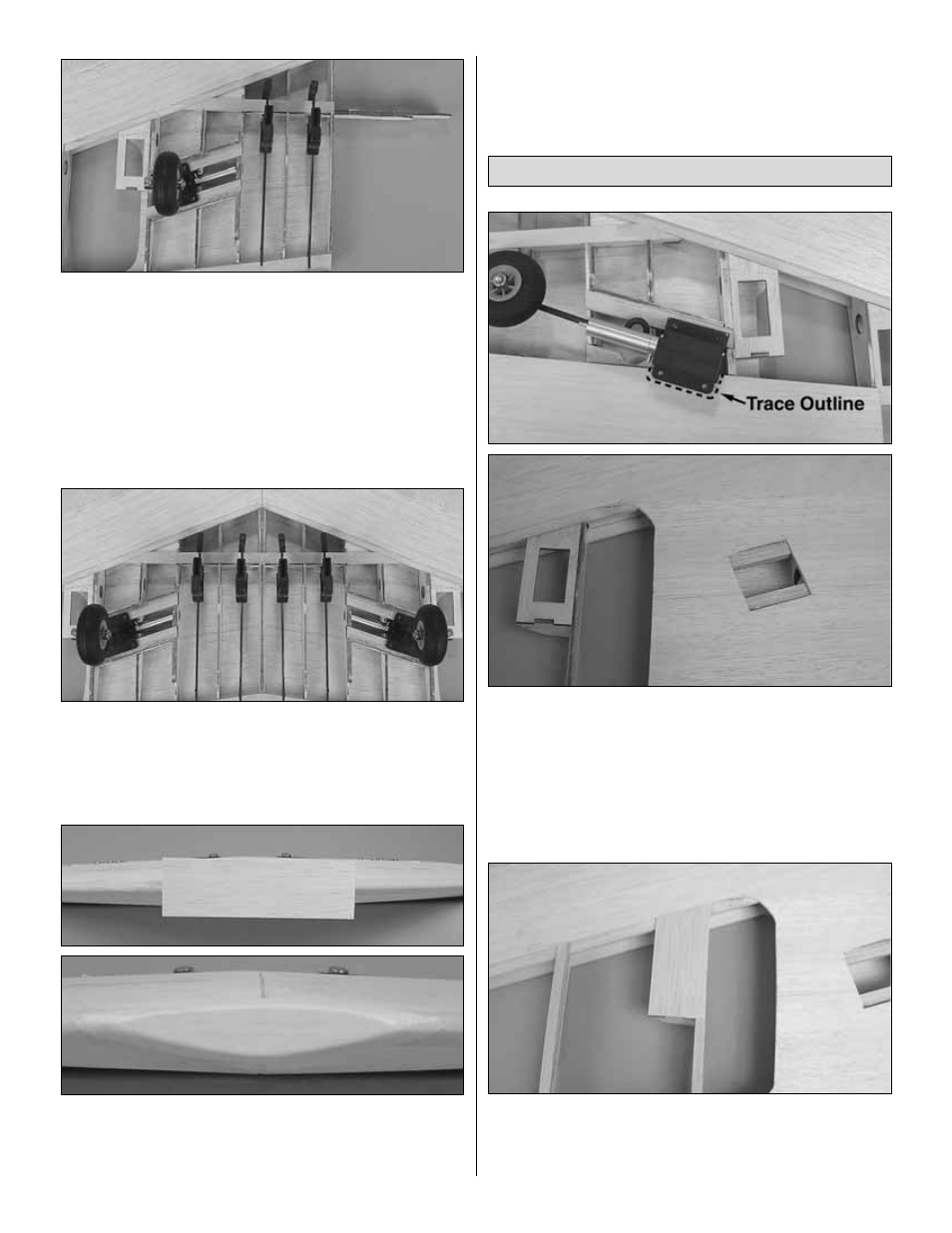

1. Sheet the bottom wing in the same manner as the

top, one half at a time. You will need to make a cutout for the

landing gear in the sheeting. The way we did this was to

install the first section of sheeting flush with the TE sheeting,

then position the gear. Trace the outline of the gear onto the

sheet. This way, you can align the plate with the outline when

the second sheet is glued and trace the remainder of the

cutout. Do not glue the sheeting to the areas to be cut out.

❏ ❏

2. If you installed the flap servo tray, sheet it at this

time. Cut a piece of sheeting flush with the LE sheeting that

covers the tray. Glue a cap strip from the bottom of the servo

tray to the TE sheeting as shown.

Sheet the Bottom of the Wing

20