Great Planes Patriot XL Kit - GPMA0450 User Manual

Page 34

❏

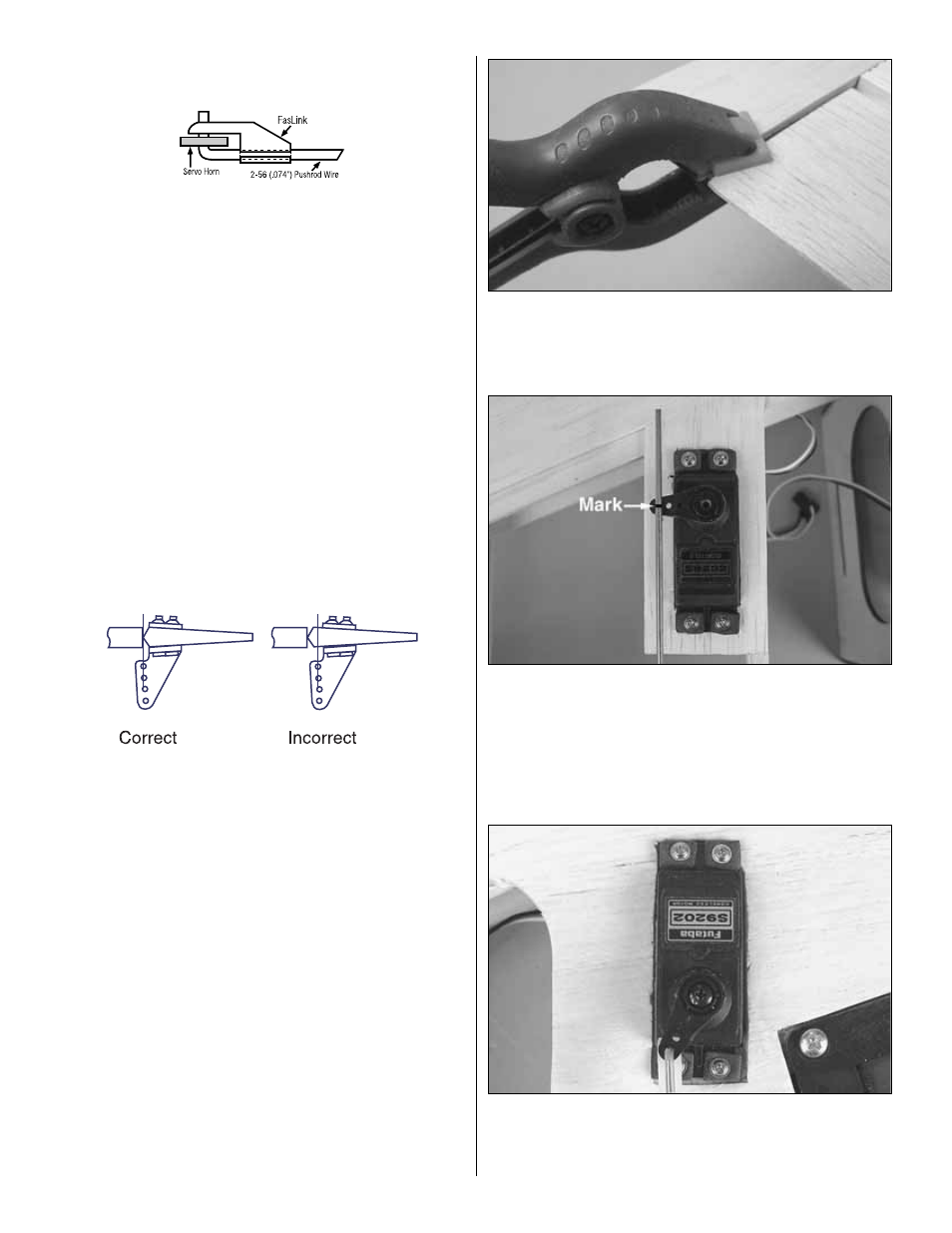

8. Thread a nylon swivel clevis and retainer onto the 12"

[300mm] pushrod (threaded on one end). Connect the clevis

to the rudder torque rod and mark the point where the

pushrod crosses the rudder servo arm. Make a 90° bend at

that point in the pushrod. Insert the pushrod into the servo

arm. Snap in place using the nylon Faslink as shown. Trim

off all but about 1/16" [1.6mm] past the Faslink.

❏

9. Thread a nylon clevis and retainer onto the 12"

[300mm] pushrod (threaded on one end) for the elevator

pushrod. Slide the pushrod wires through the two elevator

pushrod guide tubes, which are on the left and right sides of

the fuselage. Remove the backing plate from a nylon

control horn and connect the horn to the clevis in the outer

hole. Fit the elevator to the stab, using the hinges to hold

them in place. DO NOT GLUE THE HINGES IN PLACE.

❏

10. Position the control horns on the elevators as shown in

the sketch and on the plan. Use a ballpoint pen to mark the

location of the control horn mounting holes and drill 3/32"

[2.4mm] holes at the marks. Temporarily mount the control

horn to the elevators with the backing plate and 2-56 x 5/8"

[16mm] screws.

❏

11. Attach the elevator pushrods to the servos with Faslinks

using the same procedure as you did with the rudder.

❏

12. Install the wing servos using the screws and hardware

provided by your manufacturer.

❏

13. Thread a nylon clevis and retainer onto each of the

four 6" [150mm] pushrods.

❏

14. Position the control horns on the ailerons and flaps as

shown on the plan. Use a ballpoint pen to mark the location of

the control horn mounting holes and drill 3/32" [2.4mm] holes

at the marks. Temporarily mount the control horn to the

ailerons with the backing plate and 2-56 x 5/8" [16mm] screws.

❏

15. Connect the clevis to the control horn. Center the

ailerona and position the servo arms perpendicular to the

servo case. Hint: A small clamp can help hold the ailerons

even with the wing tip as shown.

❏

16. Align the pushrod with the outer hole on the aileron servo

arm. Mark the pushrod where it crosses the servo arm. Bend

the pushrod down 90° at the mark. Enlarge the hole in the servo

arm slightly with a 5/64" [2mm] drill bit and insert the pushrod.

❏

17. Install the Faslink first, then trim to 1/16" past the

bottom of the Faslink. Do this for both aileron servos.

❏

18. The flap linkages are done the same as the ailerons

with one difference. The servo arm on the flaps will be

angled toward the flap as shown. This will give you the angle

needed to deflect the flaps to their full extent.

34