First bend, Second bend – Great Planes F4 Phantom - GPMA0440 User Manual

Page 43

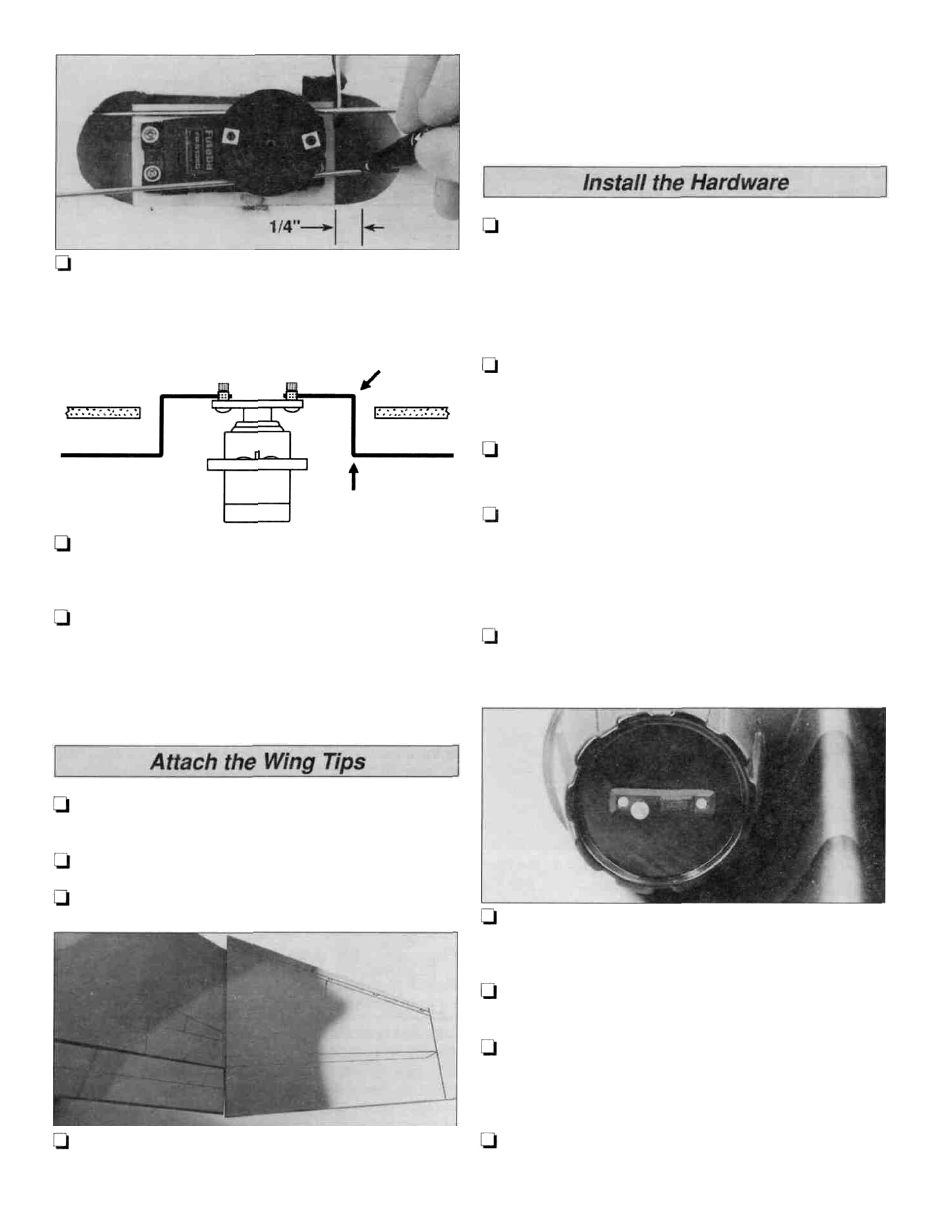

4. Pull the retract pushrods to the stops. This will lock

the gear in the down position. Mark the pushrods about

1/4" short of the servo tray. Make a 90-degree bend in the

pushrods, away from the wing.

First bend

root of the wing tip and the tip of the main wing. Join the

wing tip to the main wing, holding it in place with masking

tape. Wipe off the excess epoxy with rubbing alcohol before

the epoxy cures.

1. Assemble the fuel tank per the manufacturer's

instructions. Place 1/4" foam padding (not included) on the

tank floor and secure the tank to the floor with rubber bands

(not included) hooked over the extensions on the tank floor.

Insert two 12" pieces of fuel tubing (not included) through

the firewall. Connect one of the fuel tubes to the fuel

pick-up fitting and the other to the pressure fitting.

2. Reinstall the nose landing gear, engine mount and

engine. Apply thread lock to the bolts holding the engine to

the firewall. Shorten and connect the fuel pick-up line to the

carburetor. Connect the pressure line to the muffler.

3. Install the fixed main landing gear in the landing gear

rails, securing them with nylon landing gear straps and

#2 x 5/8" sheet metal screws.

4. Install a 3/16" wheel collar (not included) on the main

Second bend

5. Make another bend in each pushrod about 5/16"

above the first. Point the pushrods toward the pushrod

connectors on the servo.

6. Hook up and cycle the retracts a few times to make

sure that there is no interference or binding in the linkage.

Make minor adjustments as required. Trim off the excess

pushrod wire at the servo once you are satisfied with the

retract operation.

landing gear and a 5/32" wheel collar (not included) on the

nose landing gear. Install the wheels (not included) and

secure them to the landing gear with a second wheel collar.

If retracts are used, install the appropriate size wheel

collars for the axles.

5. Reinstall the radio system. Make sure the receiver

and receiver battery are wrapped in foam padding and

secured in the tail section.

1. Temporarily install the wing tip joiners in the main

wing and slide the wing tips onto the joiners.

2. Mark the outline of the main wing on the wing tip.

3. Remove the covering 1/16" inside the outline.

6. Mount the receiver switch in a convenient location.

We used a Great Planes Switch and Charge Jack mounted

in the back of one of the tail cones.

7. Switch on the radio system and center the servos.

Reinstall the servo horns and pushrods.

8. Fasten the receiver antenna along the inside of the

fuselage, toward the front of the model. We used leftover

outer pushrod tubing, cut into 1/4" long pieces, glued to the

fuselage sides as guides.

4. Use 30-minute epoxy to glue the wing tip joiners in

9. Apply 1/16" foam wing seating tape (not included) on

the main wing. Before the epoxy cures, apply epoxy to the the wing saddle of the fuselage (optional).

43