Great Planes F4 Phantom - GPMA0440 User Manual

Page 42

4. If you have not yet installed and connected the

elevators, rudder, throttle, steering and aileron pushrods,

return to "Radio Installation" on page 38 for instructions.

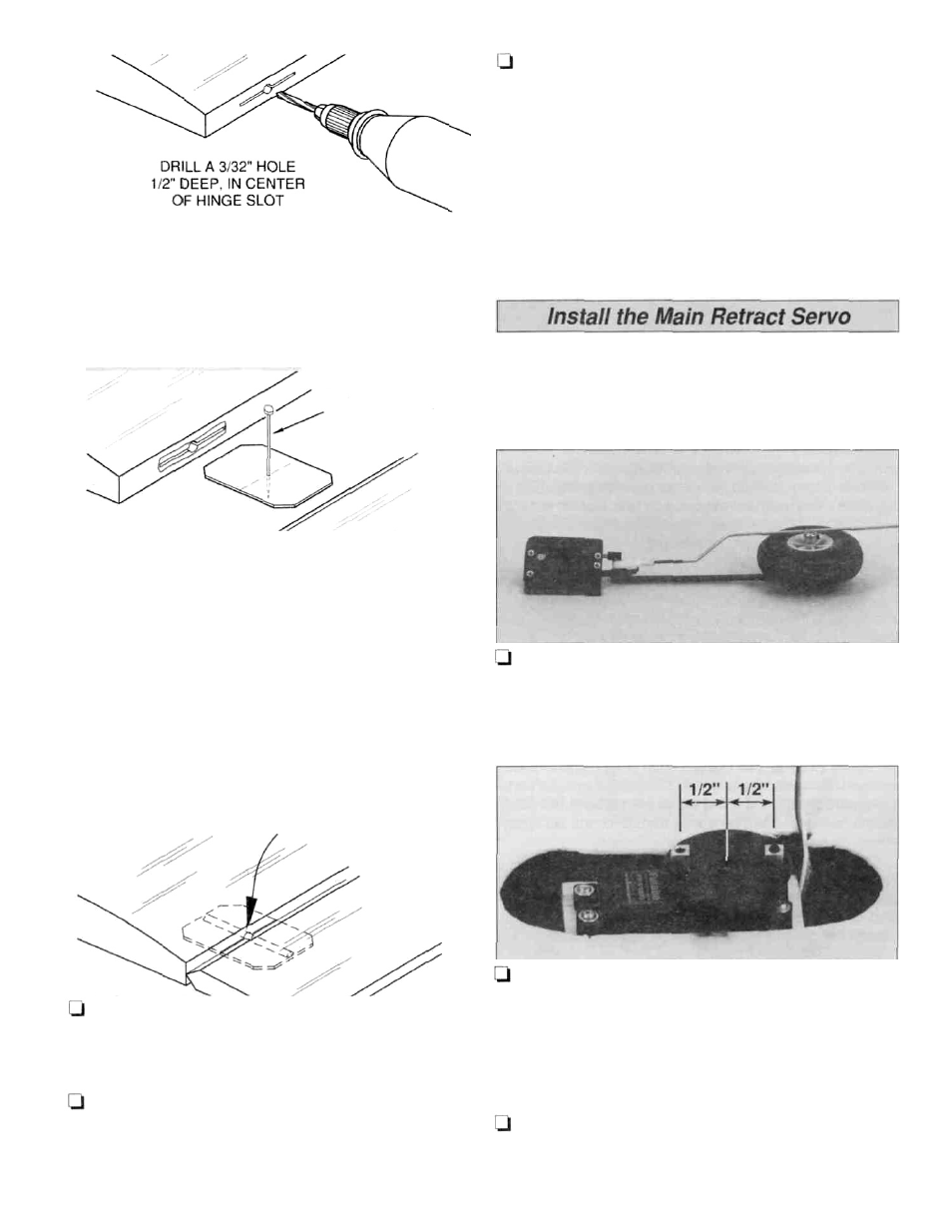

Drill a 3/32" hole, 1/2" deep, in the center of the hinge

slot. If you use a Dremel" MultiPro'" for this task, it will

result in a cleaner hole than if you use a slower speed

drill. Drilling the hole will twist some of the wood fibers

into the slot, making it difficult to insert the hinge, so you

should reinsert the knife blade, working it back and forth

a few times to clean out the slot.

TEMPORARY PIN

TO KEEP HINGE

CENTERED

It is best to leave a very slight hinge gap, rather than

closing it up tight, to help prevent the CA from wicking

along the hinge line. Make sure the control surfaces will

deflect to the recommended throws without binding. If you

have cut your hinge slots too deep, the hinges may slide

in too far, leaving only a small portion of the hinge in the

control surface. To avoid this, you may insert a small pin

through the center of each hinge before installing. This pin

will keep the hinge centered while you install the control

surfaces. Remove the pins before proceeding.

Perform steps 1 through 6 if using mechanical retracts.

Skip to the next section, Attaching The Wing Tips, if

using fixed landing gear.

1. Reassemble the main retracts and retract pushrods

that were removed from the wing during wing completion.

Install the main gear retract servo.

ASSEMBLE, THEN APPLY 6 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

2. Install the elevators on the stab and apply 6 drops of

thin CA adhesive to both sides of each hinge. Allow a few

seconds between drops for the CA to wick into the slot.

Repeat the process to install the rudder.

2. A large, round servo horn with holes drilled 1/2"

(12.7mm) from the center will work for most mechanical

retracts. Install Screw-Lock Pushrod Connectors (not

included, GPMQ3870) onto the horn as shown and install

the servo horn on the servo.

3. Pack each of the torque rod holes in the ailerons with

30-minute epoxy (a toothpick works well for this). Install the

ailerons with their hinges. Repeat the gluing technique

described previously and allow the epoxy to cure.

3. With the retract pushrods attached to the retracts,

insert the pushrods through the clearance holes toward the

servo. Mount the retracts to the retract blocks.

42