Great Planes F4 Phantom - GPMA0440 User Manual

Page 11

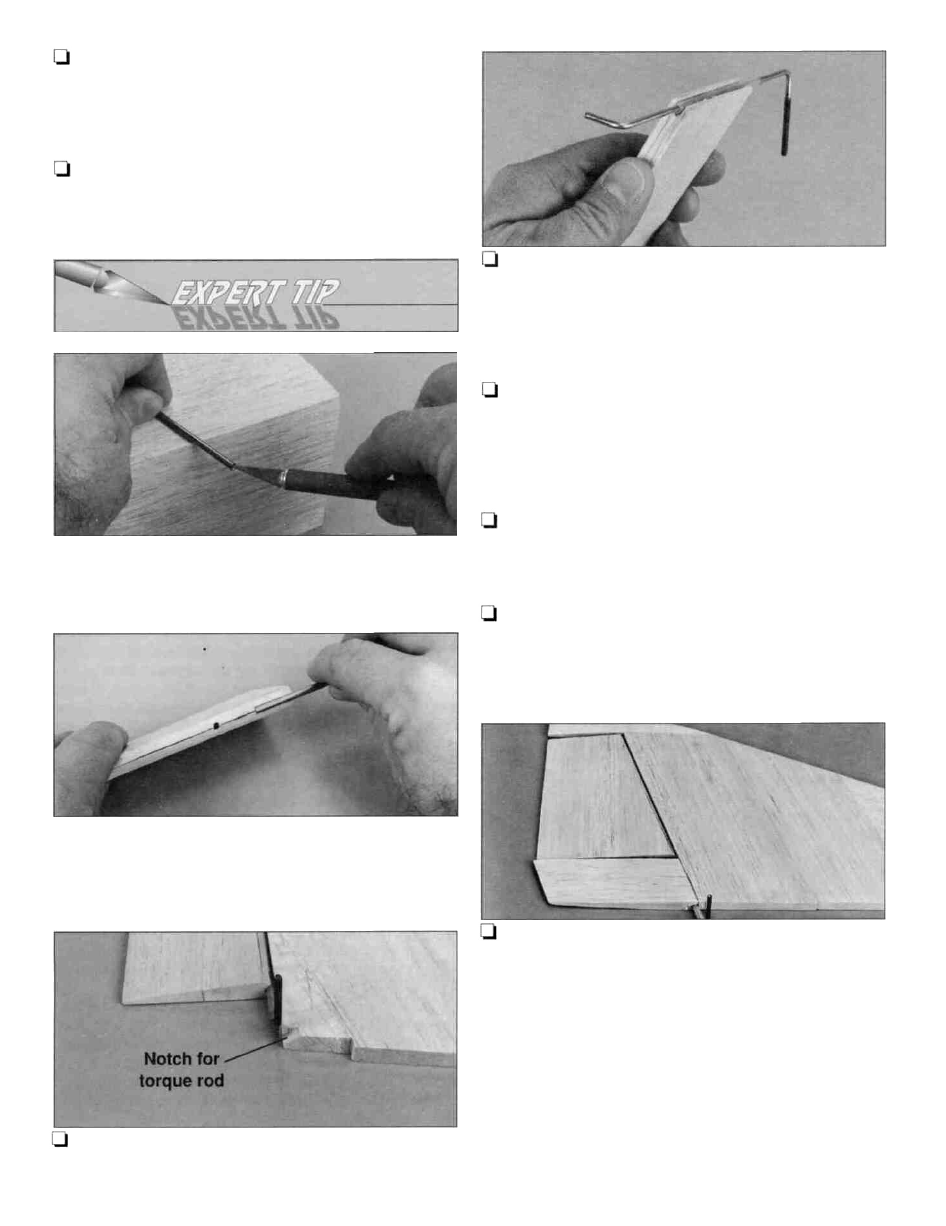

4. Drill a 3/32" pilot hole, into the elevator LE, at the

centerline and torque rod mark. As you drill the holes keep

the drill aligned with the top and bottom surfaces of the

elevator. Enlarge the holes with a 1/8" drill.

5. Cut a 1/8" groove in the leading edge of both elevators

to recess the joiner wire (see expert tip that follows).

7. Mark the centerline on the LE of the shaped 3/8"

balsa lower fin extension. Cut a groove along the

centerline for the rudder torque rod bearing. The groove

must be deep enough to encase the torque rod bearing.

HOW TO CUT A GROOVE FOR A TORQUE ROD

A. Use a hobby knife to sharpen the inside of a piece of

1/8" brass tube. Roll the tube as you carve the end.

8. Roughen the torque rod bearing with 80-grit

sandpaper. Insert the bearing in the groove in the LE of the

lower fin extension and glue the extension to the TE of the

fin, as shown on the plan.

9. Position the fin and rudder over the plan and mark the

location of the rudder torque rod.

10. Drill and groove the rudder LE for the rudder torque

B. Use the sharpened tube to carefully gouge the leading

edge. You'll have to make a few cuts to make the recess

deep enough for the torque rod.

rod, following the same procedure used previously for

the elevator.

11. Sand a taper on the lower fin extension using the

rudder as a guide.

6. Cut a notch in the stab TE to allow the torque rod to

pivot freely.

11