Great Planes F4 Phantom - GPMA0440 User Manual

Page 18

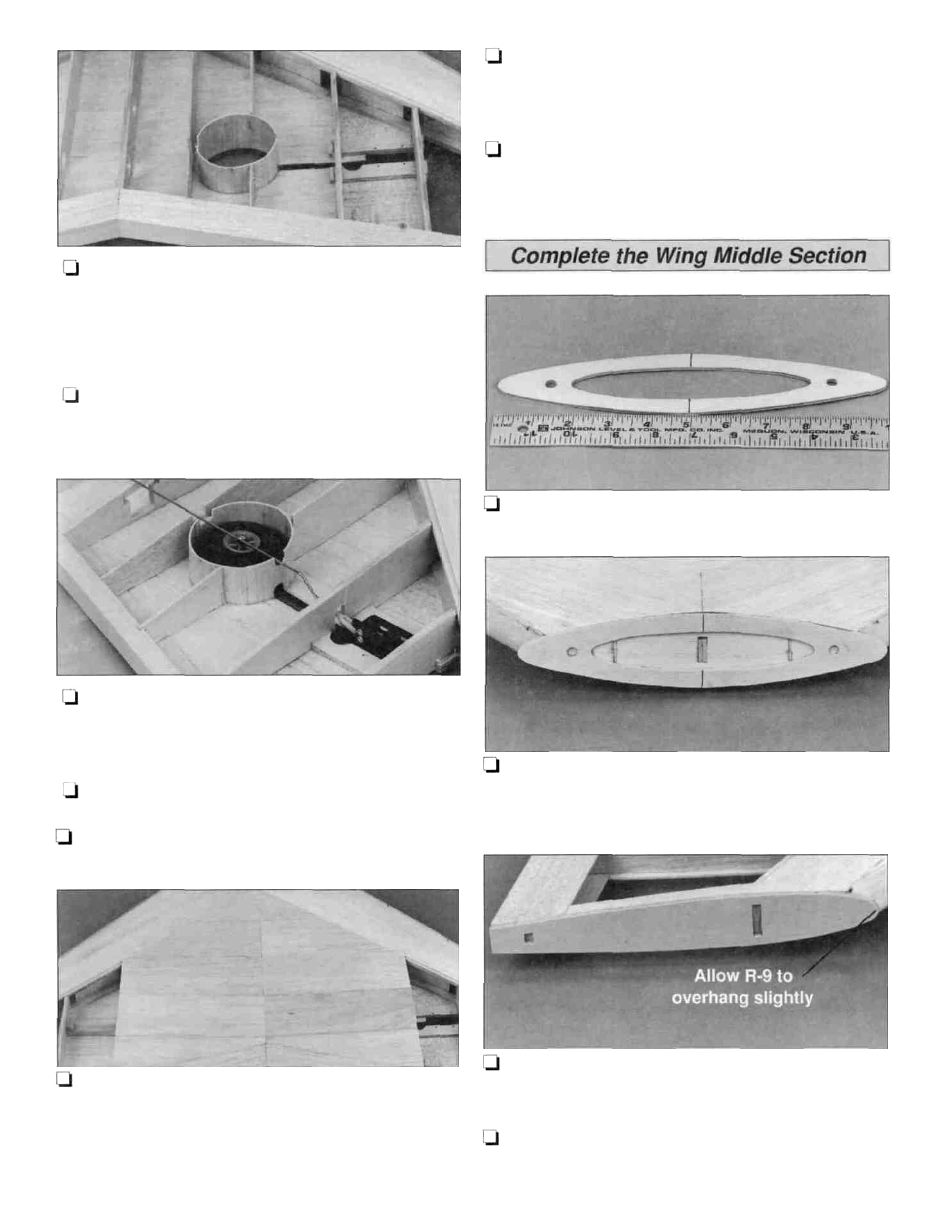

11. The wheel well liners can be made from foam or

17. From the 1/16" x 3/8" x 30" balsa stick, cut and glue

cap strips to the top of ribs R-5, R-6, R-7 and R-8. The

edge of the cap strip on R-8 should be flush with the side of

the rib.

18. Trim and sand the LE and TE sheeting flush with the

side of rib R-8.

paper cups of the proper size, or from vertical grain 1/16"

balsa sheeting wrapped around an appropriately sized

glass jar and glued to form a cylinder. Glue the wheel

wells in place and sand the edges flush with the top of

the ribs and the bottom sheeting.

12. Cut a groove in rib R-2 and the wheel well liner for

the retract actuating rod to pass through. Thread a nylon

clevis (not included, GPMQ3800) 13 turns onto the end

of a 2-56 x 12" wire pushrod (not included, GPMQ3750).

13. Connect the clevis to the retract. Bend the retract

pushrod to clear the wheel and be below the top of the

ribs. Avoid making sharp bends. Remember, the pushrod

will need to be installed after the top sheeting is installed.

1. Draw a centerline on the die-cut 1/8" plywood front cap.

2. Use 30-minute epoxy to glue the front cap to the front

sub cap. Use the centerlines on the front cap as guides to

center it on the front sub cap.

14. Remove the retracts from the wing.

15. Fit and glue the 1/16" x 1-1/2" x 24" TE sheet to the

TE, sub TE and the top of the ribs.

16. Sheet the right top center section of the wing from

3. Use 30-minute epoxy to glue the die-cut 1/8" plywood

the center of ribs R-1 to R-4 using 1/16" x 3" x 30" balsa

sheets. Before sheeting the top left center section, mark the

location for the aileron and retract servo trays on the top

right center sheeting.

4. Sand all the edges even on the center TE plate and

the TE of the wing.

18