Great Planes F4 Phantom - GPMA0440 User Manual

Page 20

Perform the following operation in a well ventilated

area with a fan directing the air flow away from you.

D. Starting at the LE, flow thin CA into the cloth. Smooth

the cloth down with the squeegee as you work toward the

TE. Avoid standing directly over the work, as the CA

fumes can be quite irritating to your eyes and nose.

E. Allow the CA to cure naturally without using any

accelerator. When thoroughly cured, lightly sand the

edges with 150-grit sandpaper to remove any edges.

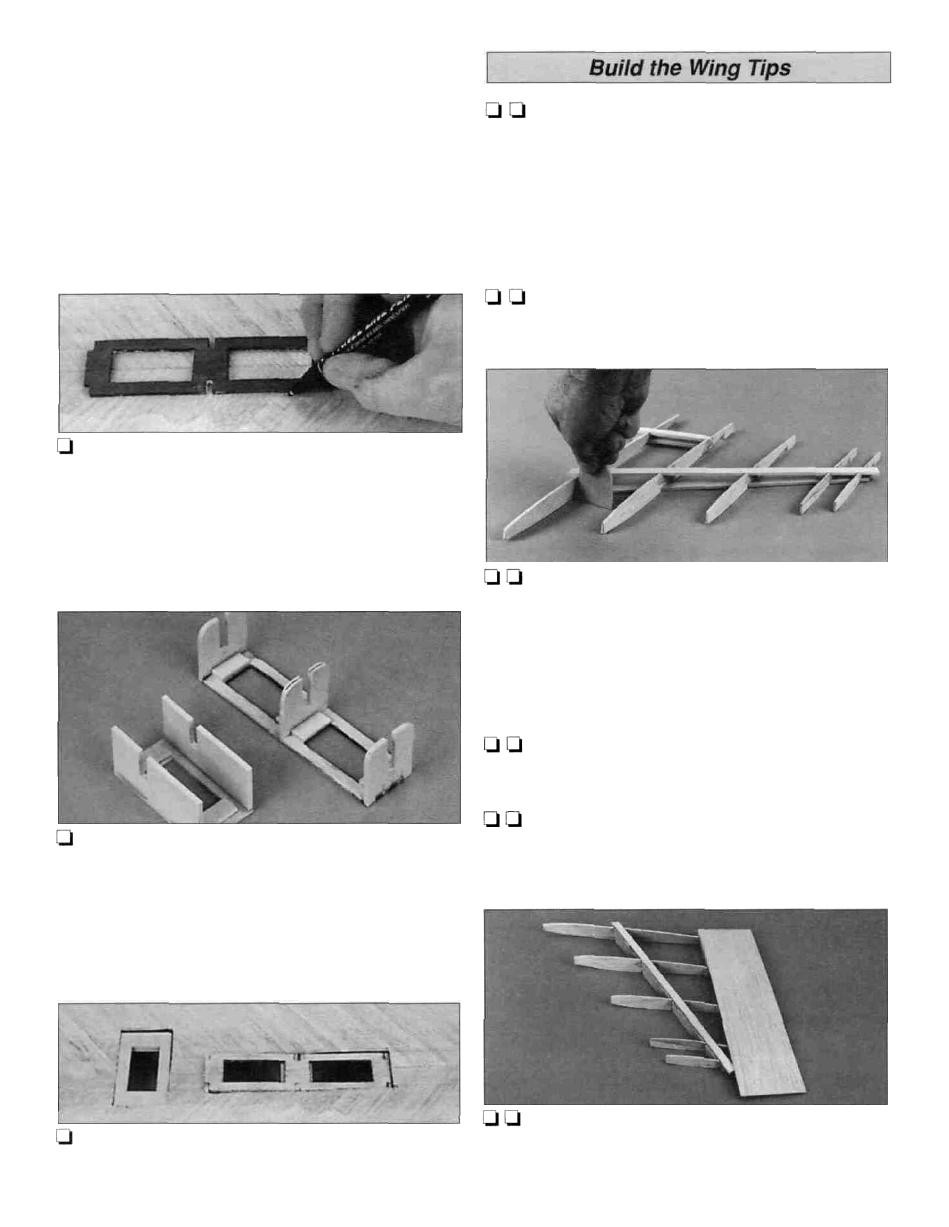

1. From a 1/8" x 3/8" x 23-7/8" balsa spar cut the

forward and aft bottom main spars slightly longer than

the lengths shown on the wing tip plan. Use the

cross-pinning technique to pin the root of the forward main

spar over the wing plan. Place a leftover piece of 1/16"

balsa sheet under the tip of the main spar to raise the spar

to meet the notch in the rib. Pin the spar to the building

board. Use leftover balsa to raise the aft spar to meet the

notches in the rib. Pin the aft spar to the building board.

13. Place the die-cut 1/8" plywood aileron servo tray

on top of the marks you made in step 16 of Sheet The Top

Of The Wing. Mark the outside perimeter of the tray and

cut the wing sheeting from inside the lines. If you are

installing mechanical retracts, perform the same procedure

for the retract servo tray. If you are installing pneumatic

retracts, the control valve and mini servo are installed in

the fuselage.

over the plan, perpendicular to the building board.

3. Cut the forward and aft top spars from a second

2. Pin the die-cut 3/32" balsa ribs T-3 through T-6

14. Glue the die-cut 1/8" plywood aileron servo tray

supports to the middle and ends of the aileron servo tray.

Make sure the supports are perpendicular to the tray. Glue

the servo tray doublers against the supports. If installing

retracts, glue the die-cut 1/8" plywood retract servo tray

supports to the side of the die-cut 1/8" plywood retract

servo tray. Glue the servo tray doublers flush with the end

of the servo cut-out.

15. Trim the balsa from over the servo locations in ribs R-1.

Glue the servo trays to the ribs.

1/8" x 3/8" x 23-7/8" balsa stick. Position the forward spar

on the ribs. Use the die-cut 1/8" plywood rib gauge to set

the angle of rib T-2. Place the gauge between ribs T-2 and

T-3 with the base against the bottom of rib T-2. With the

remaining ribs perpendicular to the building board and the

spars seated in the notches, glue the top and bottom spars

to the ribs.

4. Trim and qlue the 3/32" x 2-1/4" x 3" balsa shear

webs, perpendicular, to the front of the forward main spars.

5. Move any pins from behind the aft main spars to in

front of the aft main spars to hold the jig tabs against the

building board.

6. From a 1/16" x 3" x 30" balsa sheet, cut a 12" long

TE sheet. Glue the TE sheet to the aft end of the wing tip,

starting at the front of the aft main sub spar.

20