Great Planes F4 Phantom - GPMA0440 User Manual

Page 35

12. Enlarge the holes in the belly pan to 1/2". Reattach

We highly recommend that all plastic joints and screw

holes be strengthened with fiberglass cloth and thin CA on

the inside of the joint.

the wing to the fuse. Cut the 1/2" diameter paper tube in

half and slide the halves into the bolt holes, pushing the

tube over the head of the bolts. The holes may need to be

enlarged slightly to allow the tubes to slide in.

13. Carefully glue the paper tube to the belly pan with

thick CA. Be careful and use only a couple of drops of

CA to prevent gluing the wing bolts in place.

14. Remove the wing bolts and finish gluing the tube to

the belly pan and wing bolt plate. Cut off the excess tube

and sand it flush with the belly pan.

Skip to ASSEMBLE THE PLASTIC PARTS if retracts are

not used.

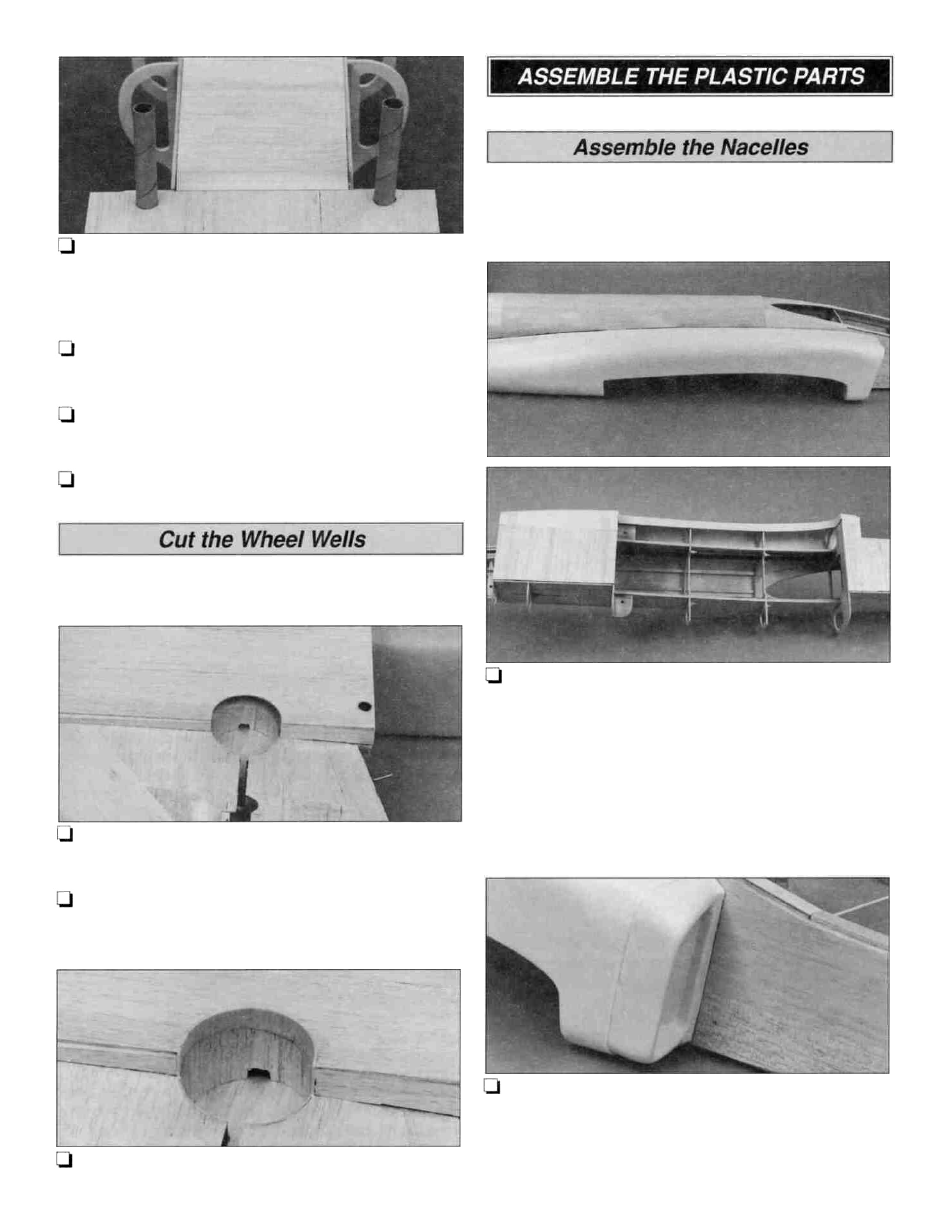

1. Carefully cut the wheel well opening in the belly pan

1. Trim the plastic nacelles along the embossed cut

lines. You can use a hobby knife to carefully score along

the cut lines and flex the plastic until the excess breaks

free, or use small scissors to cut along the cut line. Kyosho

curved Lexan scissors (KYOR1010) work extremely well.

Test fit the nacelles to the side of the model. The top of the

nacelles fit in the groove between the fuse sides and

turtledeck. When satisfied with the fit, tape the nacelles to

the fuselage.

15. Harden the paper tubes by soaking them with thin CA.

1/16" larger than the wheel well in the wing. A Dremel' tool

with a sanding drum works great for this.

2. Cut out a wheel well liner from a leftover piece of

1/16" balsa wing sheeting. Wet the liner and glue it to the

belly pan and the bottom wing sheeting.

3. Sand the wheel well liners flush with the belly pan.

2. Trim the plastic inlets along the embossed cut lines.

Fit the inlets on the front of the nacelles and against the

fuse sides. When satisfied with the fit, sand the inside edge

of the inlets and the lip on the nacelles and glue them

together with thin CA.

35