Great Planes F4 Phantom - GPMA0440 User Manual

Page 23

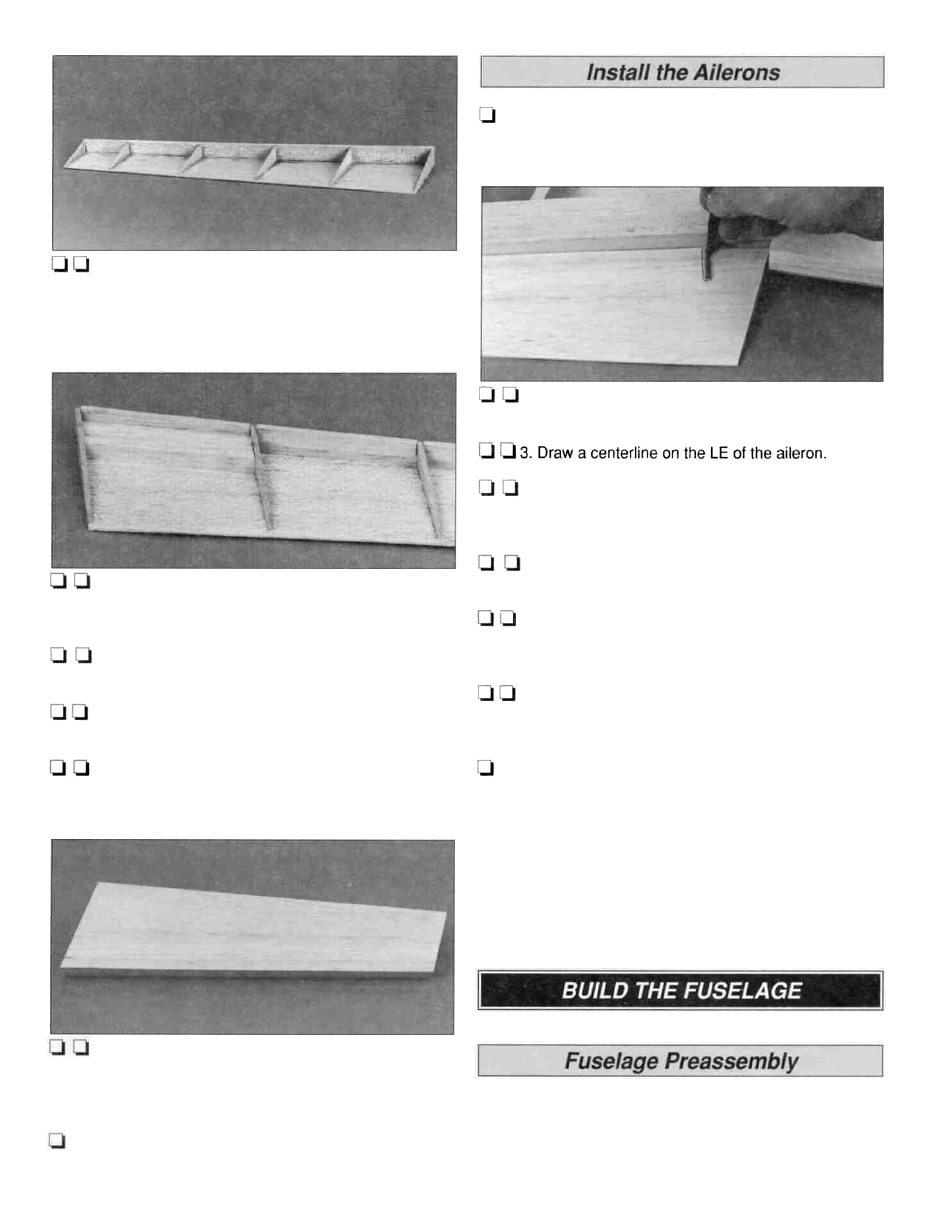

3. Slide the die-cut 1/8" balsa aileron sub LE over the

ribs and glue the ribs and aileron sub LE to the aileron sheet.

Note: The sub LE angles aft slightly.

4. Cut a torque rod block from the 3/8" x 3/4" x 8"

1. Check the fit of the ailerons between the wing tips and

the wing center TE plate. A gap of 1/32" to 1/16" at each end

is large enough to allow for covering without binding.

2. Place the left aileron on the trailing edge of the

wing and mark the location of the torque rod.

4. Drill a 1/8" hole on the centerline for the aileron

torque rod. Use sharpened 1/8" and 3/16" brass tubes to

cut a groove in the LE for the aileron torque rod.

5. From the leftover hinge material, cut three

aileron hinges.

balsa stick. Glue the block in the corner between ribs A-1

and A-2.

6. Mark the location for the hinges on the aileron and

5. Sand the TE of the aileron sheet to match the

wing. Cut the hinge slots, and without using glue, test fit the

aileron onto the wing.

6. Glue the second die-cut 1/16" balsa aileron sheet to

angle of the aileron ribs.

the top of the aileron ribs, sub LE and bottom aileron sheet.

7. Remove the aileron from the wing. Mark the "bevel

to" lines and trim the LE of the aileron to a "V" as shown on

the plan.

7. Sand the aileron sub LE and the top and bottom

8. Perform steps 2 through 7 to fit the right aileron onto

sheet flush. the wing.

Great looking w i n g ! Now the only section left is the

easy-building fuselage.

8. Glue the 3/8" x 7/8" x 13-1/2" balsa aileron LE

onto the front of the aileron sub LE. Sand the LE flush with

the top and bottom aileron sheet and ribs A-1 and A-6.

9. Go back to step one of this section and build the

opposite aileron.

Completely read this section on Fuselage Preassembly and

test fit all the parts. These parts require the strength and

working time of 30-minute epoxy glue. This extra working

time will allow you to assemble most of the parts at once.

23