Great Planes F4 Phantom - GPMA0440 User Manual

Page 33

10. Fill the gap between the stabilizer and former F-10

with leftover pieces of 3/16" die-sheet from the belly pan

sides. Sand the filler flush with the fuse sides, the bottom

of the stab and former F-10.

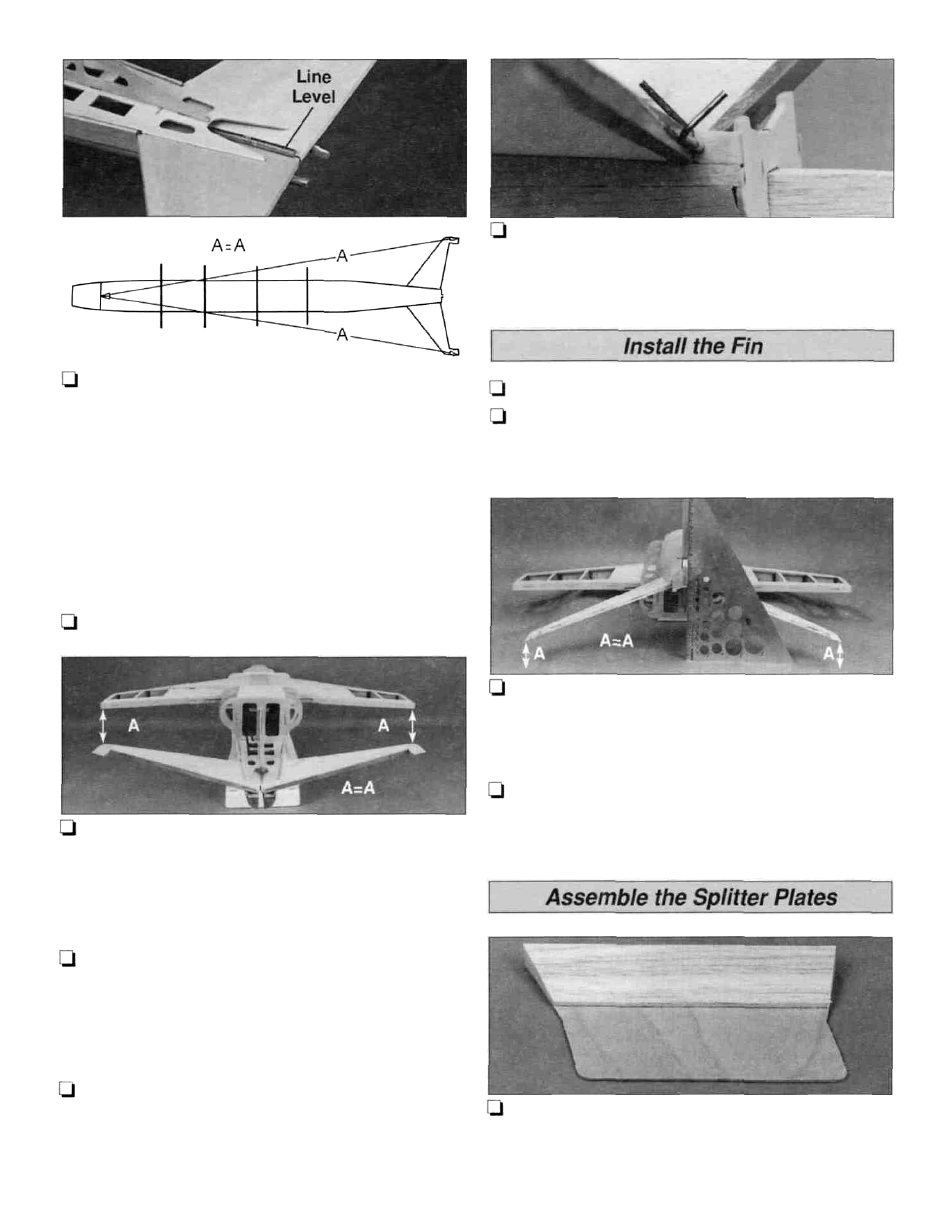

5. Mount the wing on the fuselage. Without gluing,

insert the stab in the slot between the fuse sides and radio

tray, centering it visually. Carefully trim the LE so that the

stab contacts former F-9, fuse sides and radio tray. Use a

string or measuring tape to measure the distance from

each stab tip to a pin centered in the bottom of F-1. The

distance to the pin must be equal from each stab tip.

Important: Position the plane on an airplane stand so that the

incidence of the wing is at 0%. Set a level at the centerline of

the stab to check that the stab incidence is 0%. A line level

found at most hardware stores works great for this.

6. Mark reference lines on both sides of the stab bottom.

7. Position the model so that you can sight it several feet

away from the front and rear. Check the distance from the

stab tips and the bottom of the wing. The distance must be

equal. If not, sand the high side of the slot slightly to

correct the situation. Recheck the incidence and when

satisfied, remove the stab.

1. Permanently glue former F-10 in position.

2. Final sand the fin and test fit it in position. You may

need to widen the slot in the TE of the stab for the rudder

torque rod. Check that the fin contacts the turtledeck. If not,

lightly sand the bottom of the fin.

3. Place the model on your building board and place

shims under the fuselage until both stab tips are an equal

distance from the building board. Use a 90-degree building

triangle to set the fin perpendicular to the building board,

sanding the slot as necessary.

4. Use 30-minute epoxy to glue the fin in the fin slot, the

top of the stab and the top of the turtledeck. Check that the

fin is perpendicular to the building board once again before

the epoxy cures.

8. We recommend a mixture of 30-minute epoxy and

milled fiberglass (for additional strength) to glue the stab to

the fuse. If you do not have milled fiberglass, 30-minute

epoxy will work fine alone. Glue the stab to the fuse sides,

F-9 and the radio tray. Before the e p o x y cures,

recheck the alignment from all points of reference.

9. Apply petroleum jelly on the elevator torque rods

where they exit the nylon torque rod bushings. This will

prevent the torque rods from becoming glued to the

bushings. Use epoxy to glue the elevator torque rods in the

TE of the stab.

1. Cut and glue a piece of leftover 3/8" x 1-1/4" balsa

elevator TE to the aft side of the die-cut 1/16" plywood

splitter plates. Sand the ends of the TE flush with the

edges of the splitter plate.

33