Glue the stabilizers in place – Great Planes F-15 Eagle 40 Kit - GPMA0438 User Manual

Page 25

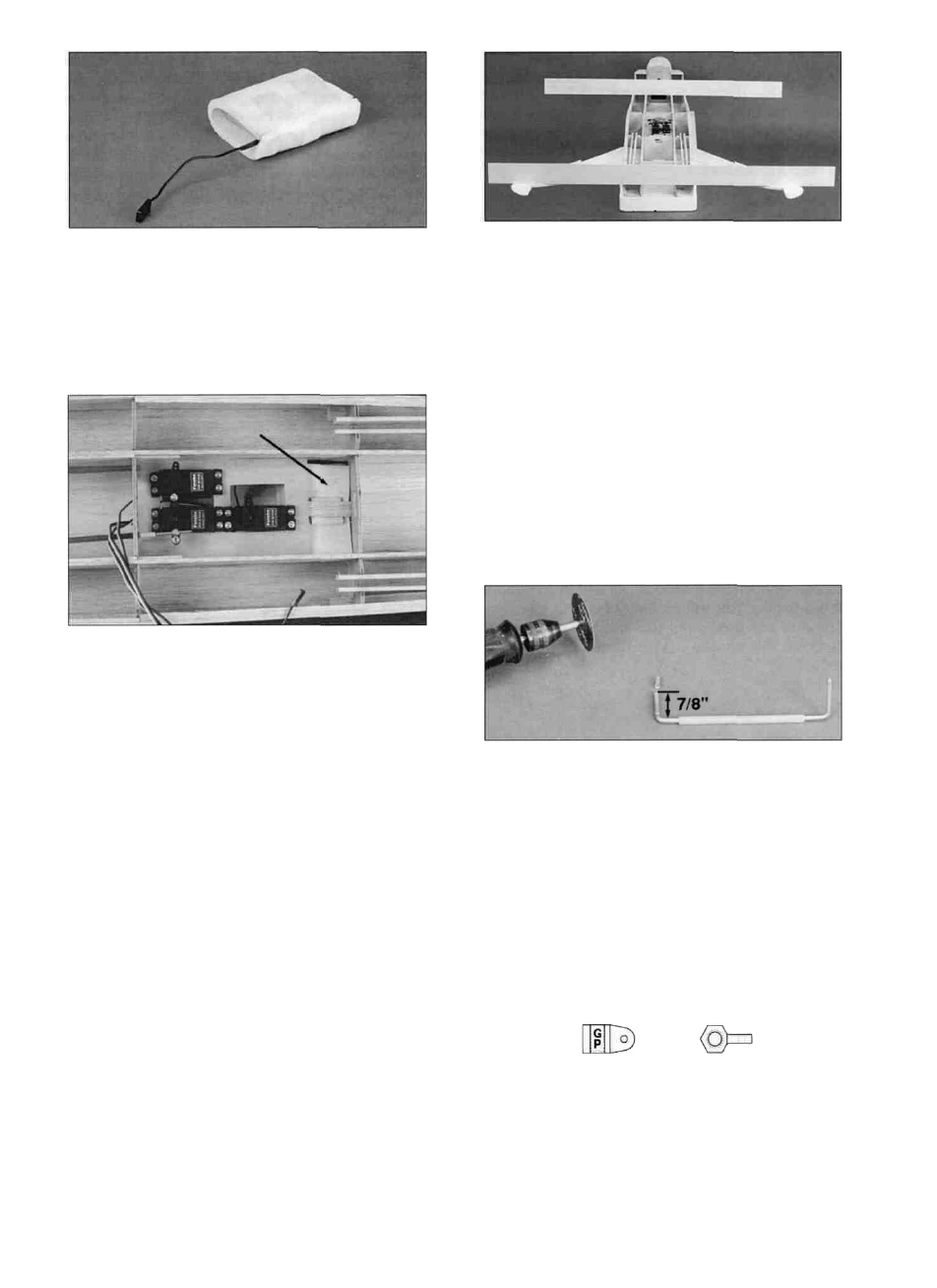

D 2. Wrap the battery in at least 1/4" of latex

foam rubber and secure the foam with tape.

D 3. Slide the battery down behind the elevator

servo and route the battery wire up between the

rudder and throttle servos. Glue a scrap piece of

balsa from F6 to the servo tray to hold the battery

in place.

D 2. Using the long piece of wood (aileron)

across the stabs as a guide, adjust the stabs until

they are level with each other and the wing saddle

(sight from behind the plane when doing this).

Securely glue the stabs to the fuse sides, the

turbine sides, the stab braces and the formers.

D 3. Insert the torque rods into place and

temporarily install the elevators and hinges. Make

sure the torque rods fit nicely and the elevators

move freely without binding anything. Also make

sure that both elevators are aligned with each

other when the threaded ends of the torque rods

are aligned.

GLUE THE STABILIZERS IN PLACE

D 4. Cut off the threaded end of the torque rod

7/8" above the bend as shown in the photo. Clean

up the cut with a file or cut-off wheel so the threads

are not damaged. Scuff up the outside of the

nylon bearing with sandpaper and then slide the

bearing tube down towards the threaded end of

the torque rod. Apply a small amount of vaseline

on each end of the bearing tube to prevent glue

from getting inside the bearing.

D 1. Sand the aft part of each turbine side

smooth. Slide the stabs into their slots until they

butt up against the fuse sides. Make sure the stabs

are all the way forward in their slots. Lay an

aileron or other long straight piece of wood across

the stabs as shown in the photo. Lay another

straight piece of wood across the fuselage wing

saddle.

D 5. Use the 6-32 thread-cutting screw

(SCRW103) to tap the holes in two of the nylon

torque rod horns (NYLON95).

24