Fuselage assembly – Great Planes F-15 Eagle 40 Kit - GPMA0438 User Manual

Page 11

and 2" long, from the border of a die-cut 1/8" sheet.

Glue this piece to the inside of the stab tip. Sand it

to the contour of the stab as shown in the photo.

D 9. Trial fit all these parts together using the

torque rods and hinges. Check the operation of

the elevators, but do not glue anything yet.

sharpen the inside of one end of a 1/8" diameter

brass tube, and use it to cut this groove.

FUSELAGE

ASSEMBLY

PREPARE FUSE SIDES

D 6. Groove the stab TE to accept the torque

rod wire and nylon bearing tube. Ideally, the

torque rod should be centered on the elevator

hinge line. Use a sharpened 3/16" diameter brass

tube to cut the groove for the nylon bearing tube

and a 1/8" brass tube for the wire.

D 7. Using a sanding block and coarse (50 or

80-grit) sandpaper, sand both sides of each

elevator to a taper (see cross-section on plans).

The trailing edge should end up approximately

3/32" wide (Do not sand to a sharp edge). Leave

the ends square. Sand the leading edge of the

elevator to a "V-shape" as shown on the plan.

Sand the trailing edge of the stab tip to the same

taper as the elevator.

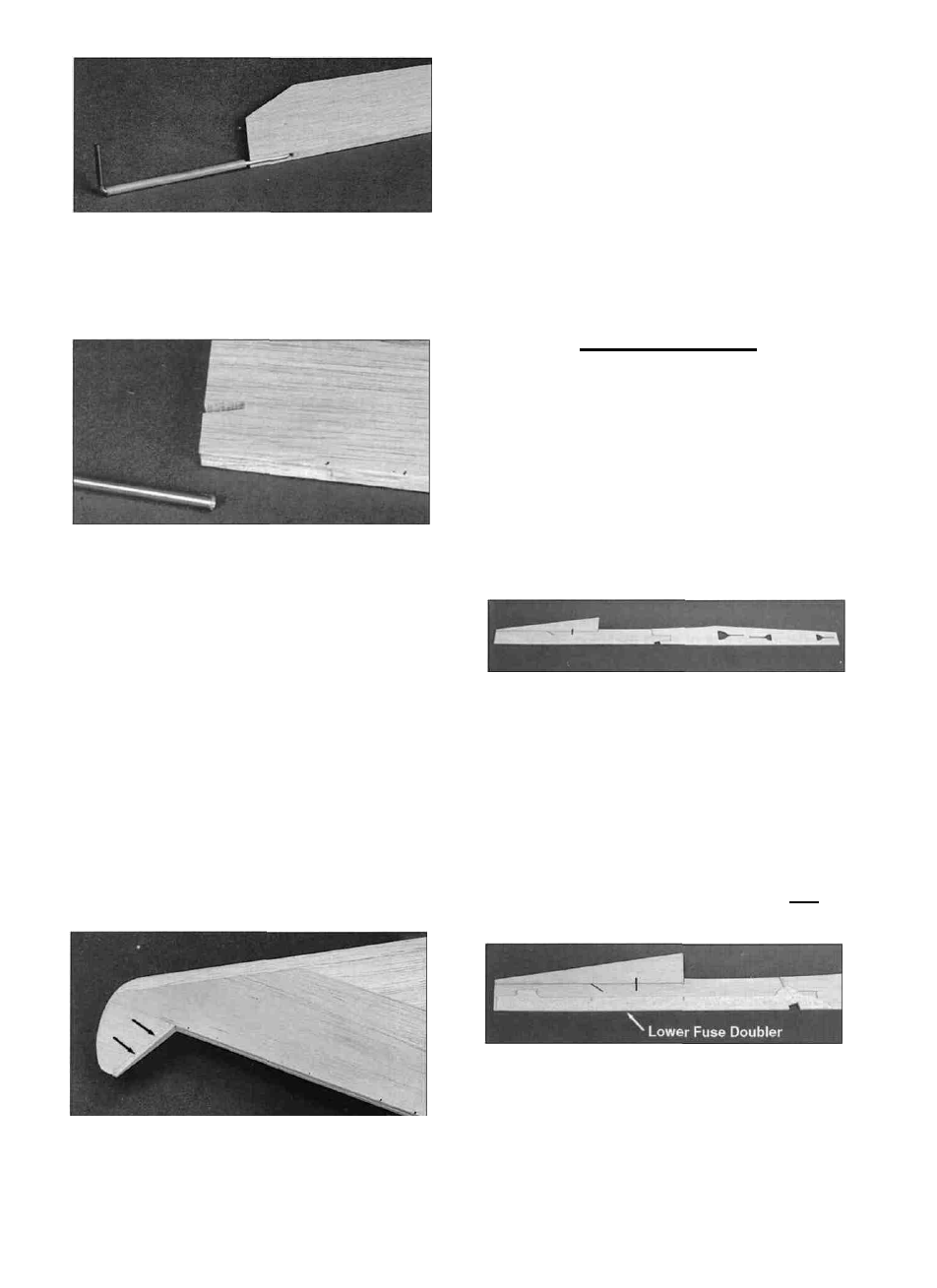

D D 1. Working over the fuselage side view

covered with waxed paper, trial fit a die-cut 1/8"

balsa forward fuse side (F154F02), forward

fuse side top (F154F03) and aft fuse side

(F154F01) together, sanding as necessary for a

good fit. Use a straight edge along the bottoms to

keep them aligned and glue them together.

NOTE: If this is your second time

through, remember to make a right and

a left side.

D D 8. Cut a piece of 1/8" balsa, 1/4" wide

D D 2. Position a die-cut 3/32" balsa lower

fuse doubler (F154F11) by lining it up with the

landing gear block cut-out and the bottom of the

fuse side. Apply thin CA all around the doubler to

glue it in place.

10