Electrical, Warning – FloAire STAGED ELECTRIC HEAT MODULE User Manual

Page 8

8

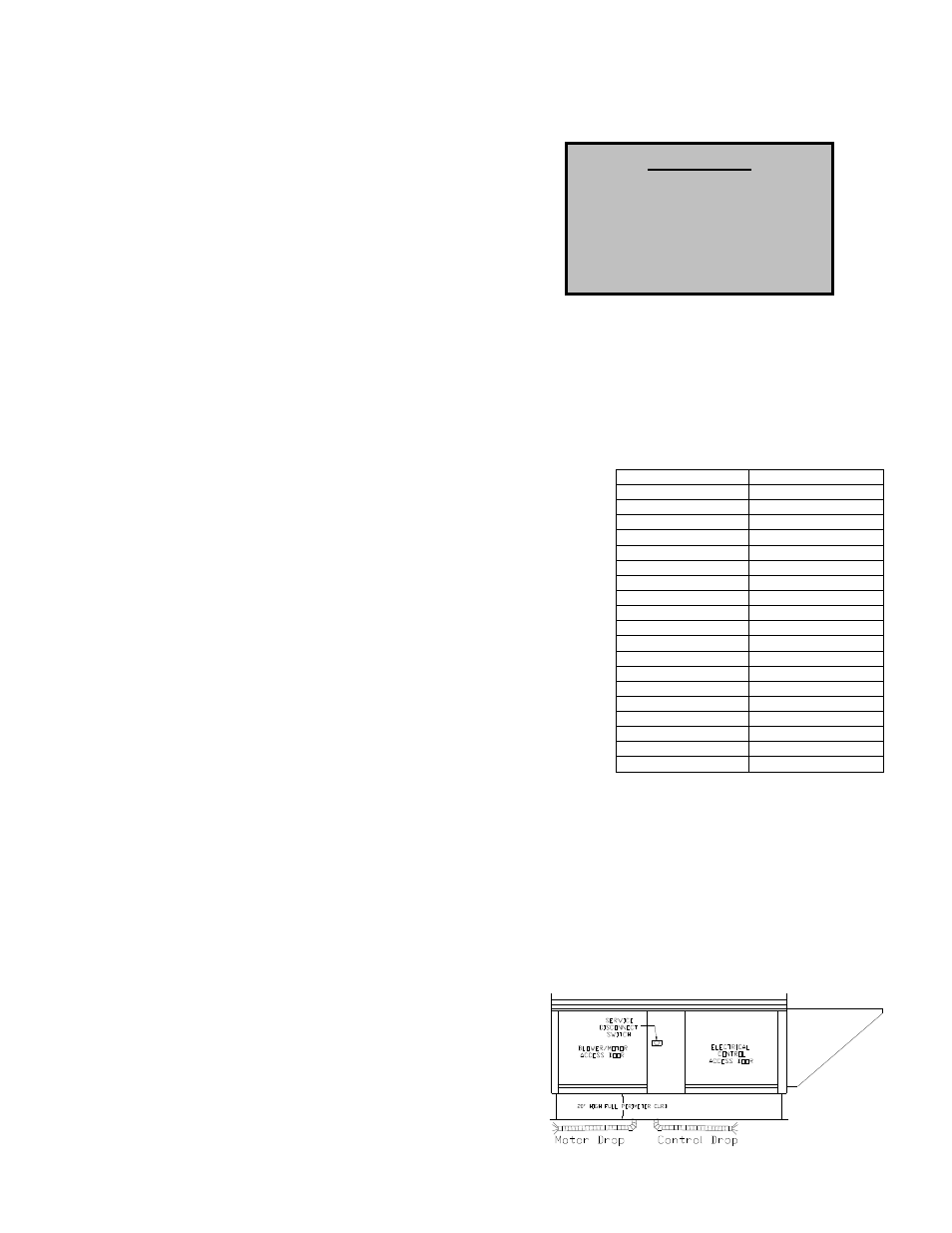

Copper Wire Ampacity

Wire Size AWG

Maximum Amps

14

15

12

20

10

30

8

50

6

65

4

85

3

100

2

115

1

130

1/0

150

2/0

175

3/0

200

4/0

230

250

255

300

285

350

310

400

335

500

380

600

420

Electrical

Before connecting power to the heater, read and understand

this entire section of this document. As-built wiring diagrams

are furnished with each fan by the factory, and are attached to

the door of the unit.

Electrical wiring and connections should be done in accordance

with local ordnances and the National Electric Code,

ANSI/NFPA70. Be sure the voltage and phase of the power

supply and the wire amperage capacity is in accordance with

the motor nameplate. For additional safety information refer to AMCA publication 410-96, Recommended

Safety Practices for Users and Installers of Industrial and Commercial Fans.

WARNING: ELECTRIC HEATERS HAVE TWO POWER INPUTS. THE EXTERNAL

DISCONNECT INTERRUPTS POWER TO THE MOTOR AND CONTROLS ONLY.

THE ELECTRIC COIL POWER IS INTERRUPTED BY THE DISCONNECT SWITCH

ON THE ELECTRIC COIL DOOR.

1. Always disconnect power before working on or near a

heater. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

2. An electrical drop containing the motor power wiring is

shipped with every fan. The electrical drop should be brought

through one of the conduit openings located in the base of the

unit, run through the curb, and connected to a junction box

inside the building.

3. A dedicated branch circuit should supply the motor circuit with

short circuit protection according to the National Electric Code.

This dedicated branch should be run to the junction box

mentioned above and connected as shown in a following

illustration labeled “Fan to Building Wiring Connection”.

4. A separate power source should supply the electric coil

power. Power from the building breaker should be wired

directly to the coil disconnect. This should be done using wire

of the proper gauge as indicated on the wire ampacity chart to

the right. A hole must be drilled in the fan enclosure to

properly run the electric coil power.

5. Make certain that the power source is compatible with the requirements of your equipment. The

heater nameplate identifies the proper phase and voltage of the motor and coil.

6. Units shipped with an optional remote panel have two electrical circuit drops. It is important to

run the motor wires in a separate conduit from the remote control wiring. The DC wires from the

unit temperature controller, located in the control drop, should be shielded cable or run in a

separate conduit.

7. Before connecting heater to the building power source, verify power line wiring is de-energized.

8. Secure the power cables to prevent contact with sharp objects.

9. Do not kink power cable and never allow the cable to come in contact with oil, grease, hot

surfaces or chemicals.

10. Before powering up the heater, check fan wheel for

free rotation and make sure that the interior of the

heater is free of loose debris or shipping materials.

11. If any of the original wire supplied with the heater

must be replaced, it must be replaced with type

THHN wire or equivalent.

WARNING!!

Disconnect

power

before

installing or servicing fan. High

voltage

electrical

input

is

needed for this equipment. This

work should be performed by a

qualified electrician.