Installation, Mechanical – FloAire STAGED ELECTRIC HEAT MODULE User Manual

Page 5

5

Recommended Supply Ductwork Sizes

Blower Size

Duct Size

Straight Duct Length

10

14 x 14

48 in.

15

20 x 20

72 in.

18

24 x 24

86 in.

20

26 x 26

108 in.

25

32 x 32

168 in.

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: DO NOT RAISE VENTILATOR BY THE INTAKE HOOD, BLOWER,

MOTOR SHAFT OR BEARINGS – USE LIFTING LUGS PROVIDED OR A SLING

Site Preparation

1. Provide clearance around installation site to safely rig and lift equipment into its final position.

Supports must adequately support equipment. Refer to manufacturer’s estimated weights.

2. Consider general service and installation space when locating unit.

3. Locate unit close to the space it will serve to reduce long, twisted duct runs.

4. Do not allow air intake to face prevailing winds. Support unit above ground or at roof level high

enough to prevent precipitation from being drawn into its inlet. The inlet must also be located at

least 10 feet away from any exhaust vents.

The heater inlet shall be located in accordance with

the applicable building code provisions for ventilation air.

Intake Assembly

Intakes are shipped on a separate skid. Upon unit arrival, follow the following procedure to assemble the

intake to the fan

1. Apply silicone or weather-proof gasket on

the back side of the flanges of the intake

hood or v-bank intake.

2. Screw the flanges of the intake hood to the

unit with the supplied sheet metal screws.

Place caulk on the outside of the screws to

prevent water leaks. If the unit is a modular

unit with a v-bank or evaporative cooler

section, the v-bank or evaporative cooler will

bolt to the heater with the bolts provided.

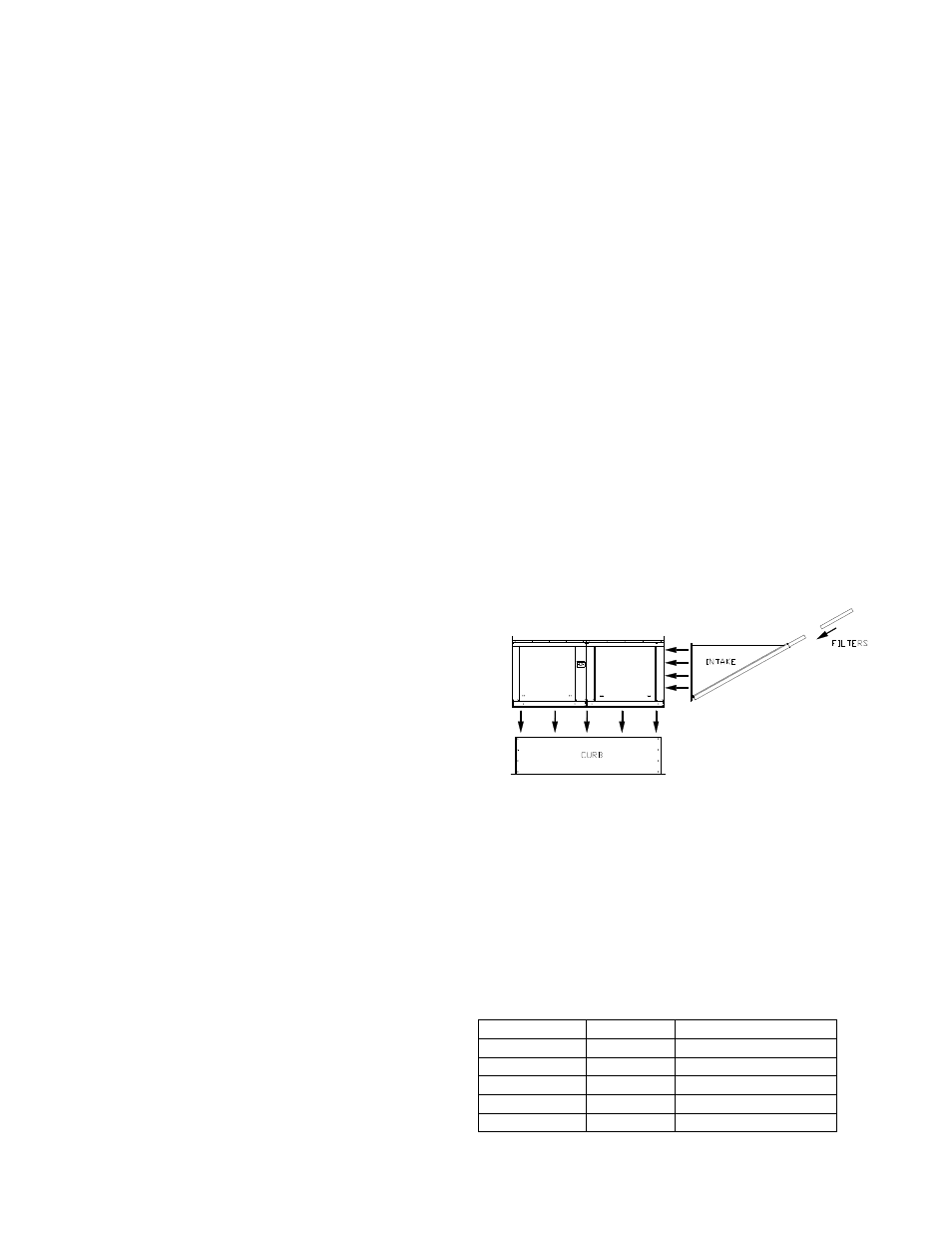

Curb and Ductwork

This fan was specified for a specific CFM and static pressure. The ductwork attached to this unit will

significantly affect the airflow performance. Flexible ductwork and square elbows should not be used.

Also, transitions and turns in ductwork near the fan outlet will cause system effect and will drastically

increase the static pressure and reduce airflow. The chart below shows the minimum fan outlet duct

sizes and straight lengths recommended for optimal fan performance. Follow SMACNA guides and

recommendations for the remaining duct run. Fans designed for rooftop installation should be

installed on a prefabricated or factory built roof curb. Follow curb manufacturer’s instructions for proper

curb installation. The unit should be installed on a

curb and/or rail elevated not less than 20” above

any surface. Be sure duct connection and fan

outlet are properly aligned and sealed. Secure fan

to curb through vertical portion of the ventilator

base assembly flange using a minimum of eight

(8) lug screws, anchor bolts, or other suitable

fasteners (not furnished). Shims may be required