EVCO EVK914N9 User Manual

Page 2

EVCO S.p.A. • Code 104K914E114 • page /5

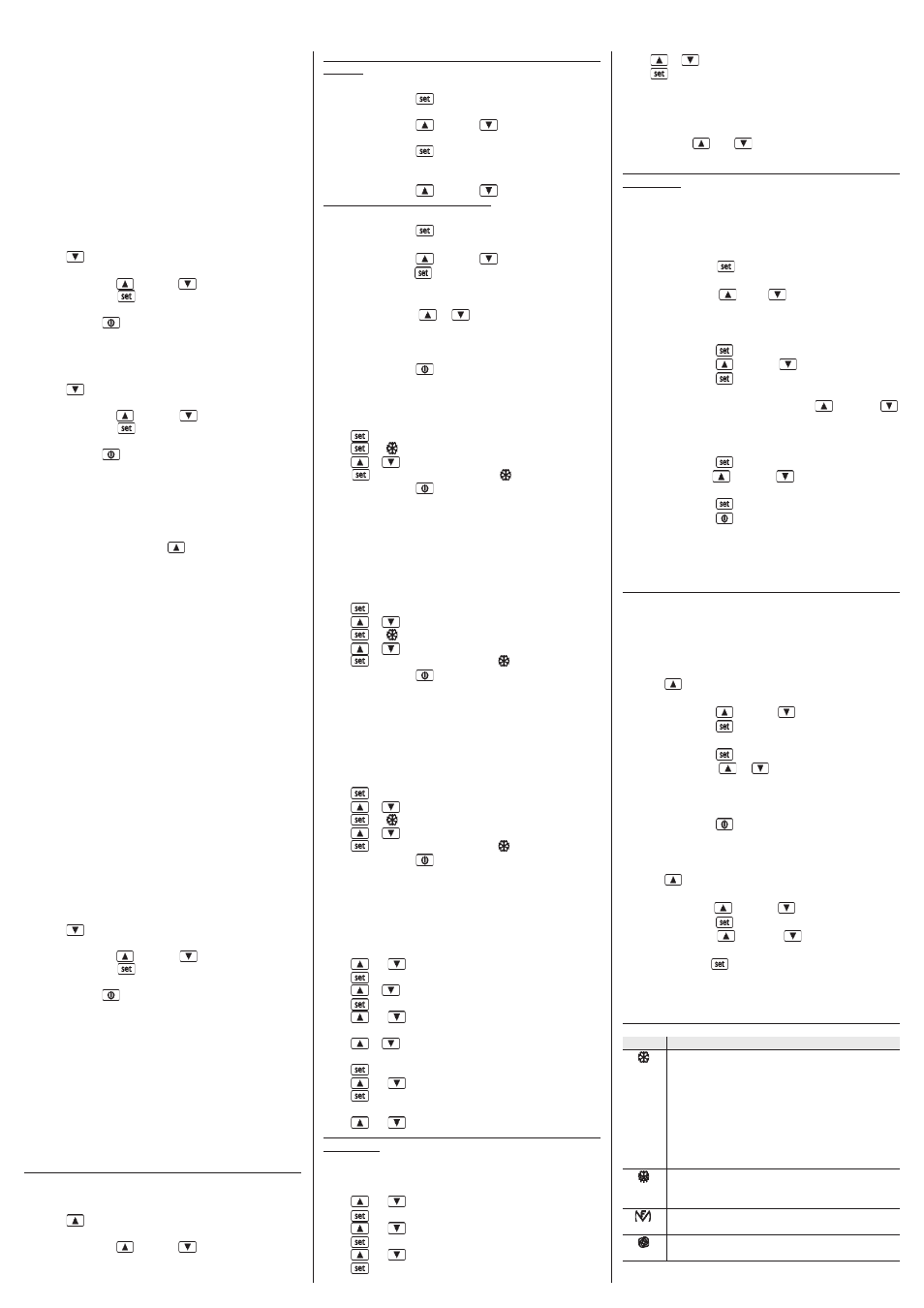

3.3 “Comfort” operation

During “comfort” operation,the compressor is switched on when the

temperature of the lower part of the DHW tank drops below the work

set point SP2 - r0” and is switched off when the temperature is above

the work set point SP2.

During this operation, the heating elements are also switched on when

the temperature of the upper part of the DHW tank and that of the

lower part drop below the “work set point SP2-r0” and are switched

off when the temperature of the upper part of the DHW tank is above

the work set point SP2.

During this operation, the fan operates in parallel to the compressor.

The “comfort” function can also be activated in manual mode, with

the following procedure:

• Make sure that the keyboard is not locked and that no other

procedure is in progress

• hold the

key down for 1 s: the display will show the first label

available

• press and release the

key or the

key to select “CMFt”

• press and release the

key

To exit the procedure before the operation is complete:

• press and release

: operation will not be activated.

The “comfort” operation can be deactivated with the following

procedure:

• Make sure that the keyboard is not locked and that no other

procedure is in progress

• hold the

key down for 1 s: the display will show the first label

available

• press and release the

key or the

key to select “ECO”.

• press and release the

key

To exit the procedure before the operation is complete:

• press and release

: operation will not be deactivated.

3.4 Defrosting

Defrosting can be activated in one of the following ways:

• automatically (when the temperature of the evaporator has remained

below the temperature established with parameter d17 for the time

established with parameter d18)

• in cyclical mode (the parameter d0 establishes the activation interval)

• in manual mode (by pressing the

key for 4 sec.

Defrosting is activated on the condition that the compressor

has remained on for at least the time established with param-

eter d18.

If the parameter P4 is set at 0 or 2, the parameter d3 will establish the

duration of defrosting; if the parameter P4 is set at 1, the parameter d3

will establish the defrosting end temperature and parameter d3 the

maximum duration of defrosting.

Defrosting is made up from the following phases:

• defrosting phase (if parameter d1 is set at 1, the compressor will be

on; if parameter d1 is set at 0 or 1, the defrosting output will be active;

if parameter d1 is set at 2, the fan will be on; parameter d3 establishes

the duration (or maximum duration) of the phase)

• dripping phase (the compressor and the fan will be off; if parameter

d1 is set at 0 or 1, the defrosting output will be active; parameter d7

establishes the duration of the phase)

• drying phase (the compressor status depends on parameter d8;

if parameter d1 is set at 0 or 1, the defrosting output will be

active; the fan is on; parameter d16 establishes the duration of

the phase).

If an “antilegionella” or “overboost” function is in progress, defrosting

will not be activated.

3.5 The “overboost” function

During the “overboost” function, the compressor, the fan and the

heating elements are on, until the temperature of the upper part of the

DHW tank rises above the work set point SP1.

To activate the “overboost” function:

• make sure that the keyboard is not locked and that no other operation

is in progress; ensure that the “normal” operation is not in progress

• hold the

key down for 1 s: the display will show the first label

available

• press and release the

key or the

key to select “ObSt”.

• press and release the

key

To exit the procedure before the operation is complete:

• press and release

: the function will not be activated.

The function is activated on condition that the temperature detected

by the probe in the lower part of the DHW tank and that of the upper

part are below set point SP3.

When the function is in progress, the display shows “ObSt” 1 sec

every 4 sec.

3.6 The “additional photovoltaic” function

During the “additional photovoltaic” function, the instrument works

as if during comfort operation, with the difference that the work set

point SP2 is increased by the temperature established with param-

eter r5.

To activate the “additional photovoltaic” function, the photovoltaic

input must be activated.

4

SETTINGS

4.1 Setting the real date and time (EVK914 only)

• Make sure that the keyboard is not locked and that no other

procedure is in progress

• hold the

key down for 2 s: the display will show the first label

available

• press and release the

key or the

key to select “rtc”.

The day is displayed in the 1... 7 format (number 1 corresponds to

Monday).

To modify the day of the week:

• press and release the

key: the display will show “dd” followed

by the two numbers of the day

• press and release the

key or the

key within 15 sec.

To change the hour:

• press and release the

key while changing the day of the month:

the display will show “hh” followed by the two numbers of the

hour

• press and release the

key or the

key within 15 sec.

The hour is displayed in the 24 h format.

To change the minutes:

• press and release the

key while changing the hour: the display

will show “nn” followed by the two minute numbers

• press and release the

key or the

key within 15 sec.

• press and release the

key or do not operate for 15 sec the clock

LED will switch off.

To exit the procedure:

• press and release the

or

key until the display shows the

temperature established with parameter P5 or do not operate for

60 sec.

Alternatively:

• press and release the

key.

4.2 Setting the DHW tank lower part work set point during

“normal” operation

• Make sure that the keyboard is not locked and that no other

procedure is in progress

• press

the display will show “SP1”

• press

the LED will flash

• press

or

within 15 sec; see also parameters r1, r2 and r3

• press

or do not operate for 15 s. the LED will switch off.

• press and release the

key.

To exit the procedure before the operation is complete:

• do not operate for 15 sec (any changes will be saved).

It is also possible to set the work set point of the lower part of the DHW

tank during “normal” operation using the parameter SP1.

4.3 Setting the DHW tank lower part work set point during

“comfort” operation

• Make sure that the keyboard is not locked and that no other

procedure is in progress

• press

the display will show “SP1”

• press

or

to select “SP2”

• press

the LED will flash

• press

or

within 15 sec; see also parameters r1, r2 and r3

• press

or do not operate for 15 s. the LED will switch off.

• press and release the

key.

To exit the procedure before the operation is complete:

• do not operate for 15 sec (any changes will be saved).

It is also possible to set the work set point of the lower part of the DHW

tank during “comfort” operation using the parameter SP2.

4.4 Setting the temperature below which it is possible to

start the “overboost” function

• Make sure that the keyboard is not locked and that no other

procedure is in progress

• press

the display will show “SP1”

• press

or

to select “SP3”

• press

the LED will flash

• press

or

within 15 sec; see also parameters r1, r2 and r3

• press

or do not operate for 15 s. the LED will switch off.

• press and release the

key.

To exit the procedure before the operation is complete:

• do not operate for 15 sec (any changes will be saved).

It is also possible to set the temperature below which it is possible to

start the “overboost” function using parameter SP3.

4.5 Setting the configuration parameters

To begin the procedure:

• make sure that no other procedure is in progress.

• press

and

for 4 s. the display will show “PA”

• press

• press

or

within 15 sec to set “-19”

• press

or do not operate for 15 s.

• press

and

for 4 s. the display will show “SP1”.

To select a parameter:

• press

or

To change a parameter:

• press

• press

or

within 15 s

• press

or do not operate for 15 s.

To exit the procedure:

• press

and

for 4 sec or do not operate for 60 sec.

Cut the device power supply off after modification of the

parameters.

4.6 Restoring the default value of the configuration

parameters

• make sure that no other procedure is in progress.

• press

and

for 4 s. the display will show “PA”

• press

• press

or

within 15 sec to set “149”

• press

or do not operate for 15 s.

• press

and

for 4 s. the display will show “dEF”

• press

• press

or

within 15 sec to set “1”

• press

or do not operate for 15 s. the display will show “dEF”

flashing for 4 sec after which the device will exit the pro-

cedure.

• cut the device power supply off.

To exit the procedure before the operation is complete:

• hold down the

and

keys for 4 sec during the procedure

(that is, before setting “1”: the settings will not be restored).

Make sure that the factory settings are appropriate (see

chapter 10).

4.7 Setting the time bands for switch-on/off of the

instrument (EVK914 only)

To begin the procedure:

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press and release the

key: the display will show “SP1”

To set the first time band:

• press and release the

or the

key within 15 sec to select

“HOn1” (first switch-on time) and/or “HOf1” (first switch-off time);

select “HOn2” and “HOF2” for the second switch-on/second switch

off

• press and release the

key

• press and release the

key or the

key within 15 sec.

• press and release the

key or do not operate for 15 sec

To associate a time band to a day of the week:

• from the previous point, press and release the

key or the

key within 15 sec to select “Hd1” switch-on time for day 1, i.e Mon-

day) and/or “Hd2... 7” (switch-on time for day 2... 7, i.e. Tuesday...

Sunday)

• press and release the

key

• press and release the

key or the

key within 15 sec to select

“1” (first switch-on/off time) or “2” (second switch-on/off time)

• press and release the

key

• press and release the

key.

To exit the procedure in advance:

• do not operate for 15 sec (any changes will be saved).

It is also possible to set these values using parameters

Hd1... 7, HOn1, HOF1, HOn2 and HOF2.

5

COMPRESSOR OPERATING HOURS COUNT

5.1 Preliminary notes

The instrument is able to store up to 9,999 hours of compressor op-

eration, after which the number “9999” starts flashing.

5.2 Display of Compressor Operation Hours

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• hold the

key down for 1 s: the display will show the first label

available

• press and release the

key or the

key to select “CH”.

• press and release the

key.

To exit the procedure:

• press and release the

key or do not operate for 60 sec

• press and release the

or

key until the display shows the

temperature established with parameter P5 or do not operate for

60 sec.

Alternatively:

• press and release the

key.

5.3 Cancelling Compressor Operation Hours

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• hold the

key down for 1 s: the display will show the first label

available

• press and release the

key or the

key to select “rCH”.

• press and release the

key

• press and release the

key or the

key within15 sec to set

“149”.

• press and release the

key or do not operate for 15 sec the display

will show a flashing “- - - -” for 4 sec then the instrument will exit the

procedure.

6

SIGNALS

6.1 Signals

LED

MEANING

compressor LED light

if the LED is on, then the compressor is on

if the LED is flashing:

• the working set point is in the process of being changed

(via the procedure described in paragraph 4.2, 4.3 and

4.4)

• compressor protection operation in progress:

- parameters C0, C1, C2

- parameters i2 and i7

Defrost LED

If it is on:

• defrosting is in progress

Heating elements LED

if on, the heating elements will be on

Fan LED

if the LED is on, then the fan is on