EVCO EVK914N9 User Manual

EVCO Hardware

EVCO S.p.A. • Code 104K914E114 • page 1/5

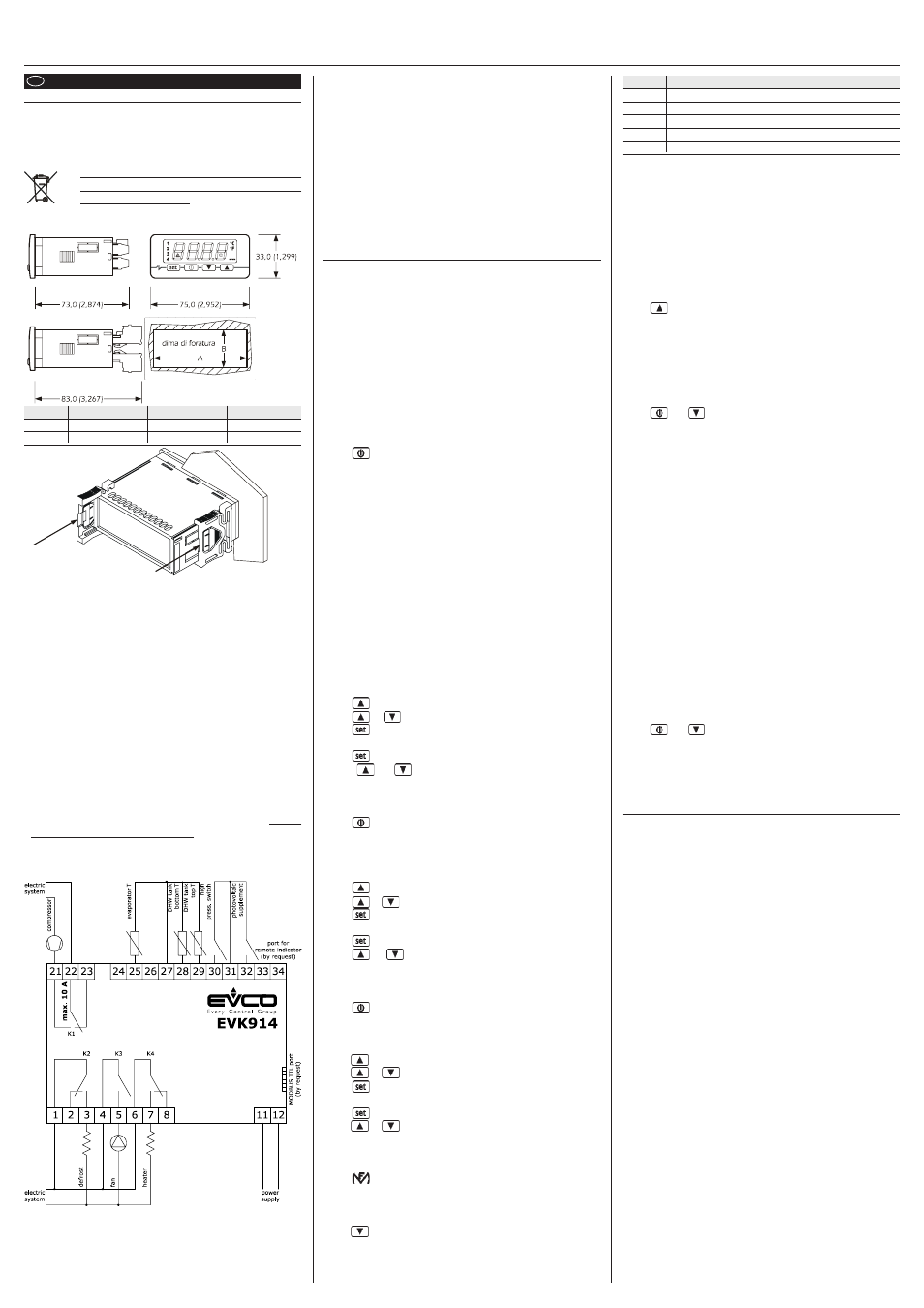

EVK904/EVK914

Controller for single-circuit residential heat pumps

version 1.1

EN ENGLISH

1

PREPARATIONS

1.1 Important

Carefully read these instructions before installing and using the product.

Pay close attention to the notes on installation and electrical wiring

connections; save these instructions together with the instrument for

future reference.

The device must be disposed of in compliance with

local Standards regarding the collection of electric

and electronic equipment.

1.2 Installation

Per panel using the snap-on brackets supplied; dimensions in mm (in).

DIMENS.

MINIMUM

TYPICAL

MAXIMUM

A

71,0 (2,795)

71,0 (2,795)

71,8 (2,826)

B

29,0 (1,141)

29,0 (1,141)

29,8 (1,173)

Installation warnings:

• the thickness of the panel must not exceed 8.0 mm (0.314 in)

• make sure that the work conditions (temperature of use, humidity,

etc.) lie within the limits indicated in technical data

• do not install the device near to any heat sources (heating elements,

hot air ducts etc.), equipment containing powerful magnets (large

diffusors, etc), areas affected by direct sunlight, rain, humidity,

excessive dust, mechanical vibrations or shocks.

• in compliance with Safety Standards, the device must be installed

correctly and in a way to protect against any contact with electric

parts; all parts that ensure protection must be fixed in a way that they

cannot be removed without the use of tools.

1.3 Electric connection

With reference to the wiring diagram:

• port 1 (on request) is the TTL serial port for communication with the

EVKEY programming key, with the Parameters Manager set-up

software (via a serial interface, with MODBUS communication

protocol) or for that for monitoring or supervision of RICS plants (via

a serial interface, with MODBUS communication protocol); the port

must be used for one purpose at a time.

• port 2 (on request) is the port for communication with the EVT100

remote indicator; the indicator displays the magnitude established

with parameter P6.

Warnings for the electric connection:

• do not use electric or pneumatic screwdrivers on the terminal boards

• if the device has been taken from a cold to hot place, the humid-

ity could condense inside; wait about 1 hour before powering

it

• make sure that the power supply voltage, the frequency and the

operational electric power of the device, correspond with those of

the local power supply

• disconnect the power supply before proceeding with any type of

maintenance

• do not use the device as a safety device

• for repairs and information regarding the device, contact the EVCO

sales network.

2

USER INTERFACE

2.1 Preliminary notes

Operating Statuses:

• “on” status (the instrument is powered and on: the regulators can be

switched on)

• the “stand-by” status (the device is powered but is off via software: the

relays are off)

Hereon, the term “switch on” means the passage from the stand-by

status to the on status. The term “switch off” means passage from the on

status to the stand-by status.

When powered, the device will be in the same status as when the

power supply was cut-off.

2.2 Instrument manual switch-on/off

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press

for 4 s.

The EVK914 model can be switched on/off also with time bands; see

HOn and HOF parameters).

Switch-on/off in manual mode always has priority over that in time

band mode.

2.3 The display

If the device is on, during normal operation the display will show the

magnitude established with parameter P5:

• if P5 = 0, the display will show the temperature of the upper part of

the DHW tank

• if P5 = 1, the display will show the current work set point

• if P5 = 2, the display will show the temperature of the lower part of

the DHW tank

• if P5 = 3, the display will show the evaporator temperature.

During the stand-by status the display is off.

2.4 Temperature display of the upper part of the DHW

tank

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press

for 2 s. the display will show the first label available

• press

or

to select “Pb1”

• press

To exit the procedure:

• press

or do not operate for 60 s.

• press

or

until the display shows the magnitude

established with parameter P5 or do not operate for 60

sec.

Alternatively:

• press

2.5 Temperature display of the lower part of the DHW

tank

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press

for 2 s. the display will show the first label available

• press

or

to select “Pb2”

• press

To exit the procedure:

• press

or do not operate for 60 s.

• press

or

until the display shows the magnitude

established with parameter P5 or do not operate for 60

sec.

Alternatively:

• press

2.6 Evaporator temperature display

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press

for 2 s. the display will show the first label available

• press

or

to select “Pb3”

• press

To exit the procedure:

• press

or do not operate for 60 s.

• press

or

until the display shows the magnitude

established with parameter P5 or do not operate for 60

sec.

Alternatively:

• press

2.7 Display of the type of operation in progress

• Make sure that the keyboard is not locked and that no other proce-

dure is in progress

• press

for 2 s. the display will show one of the codes included in

the following table.

CODE MEANING

ECO

“normal” operation

AUtO “comfort” operation

Anti

“antilegionella” operation

dEFr

defrosting

in2

active additional photovoltaic input

The display will show each code for 3 sec.

If the “Anti” code flashes:

• the temperature detected by the probe in the lower part of the

DHW tank is below the work set point during “normal” opera-

tion.

• the temperature detected by the probe in the lower part of the

DHW tank will be below the work set point during “comfort”

operation.

2.8 Manual Activation of Defrosting

• Make sure that the keyboard is not locked and that no other

procedure is in progress

• press

for 4 s.

If the evaporator probe function is that of the defrosting probe

(parameter P3=1) and upon activation of defrosting, the temperature

of the evaporator is higher than that established with parameter d2,

the defrosting function will not be activated.

2.9 Locking/unlocking the keyboard

To lock the keyboard:

• make sure that no other procedure is in progress.

• press

and

for 2 s. the display will show “Loc” for 1 s.

If the keyboard is locked, the following are not permitted:

• manual switch on/off of the instrument

• to display the temperature of the upper part of the DHW tank (with

the procedure indicated in paragraph 2.4)

• to display the temperature of the lower part of the DHW tank (with

the procedure indicated in paragraph 2.5)

• display of evaporator temperature (via the procedure explained in

paragraph 2.6)

• activate the “comfort” operation in manual mode

• activate the “antilegionella” operation in manual mode

• manual activation of defrosting

• To activate the “overboost” function

• changing the date and time

• change the work set point with the procedure indicated in

paragraphs 4.2, 4.3 and 4.4 (the work set points can also be set

through SP parameters)

• change the time bands for the switch-on/off of the instrument (with

the procedure indicated in paragraph 4.7)

• display of compressor operation hours

• cancellation of compressor operation hours

The operations cause the display of the label “Loc” per

1 sec.

To unlock the keyboard:

• press

and

for 2 s. the display will show the message “UnL”

for 1 sec.

2.10Silencing the buzzer

• make sure that no other procedure is in progress.

• press a key (pressing the key does not cause the associated effect).

If parameter u9 is set at 0, the buzzer will not be activated.

3

OPERATION

3.1 “normal” operation

During “normal” operation (i.e. if “comfort”, “overboost”,

“antilegionella” or defrosting operations are not in progress), the

compressor is switched on when the temperature of the lower part of

the DHW tank drops below the “ work set point SP1 - r0” and is switched

off when the temperature is above the work set point SP1.

During this operation, the fan works in parallel to the compressor and

the heating elements remain off.

3.2 “antilegionella” operation

The heating elements remain on in a cyclical mode (the parameter

H0 establishes the switch-on interval and the parameter H1 the tem-

perature to be reached; the differential of the parameter H1 is 2 °C/

4 °F).

If a power cut occurs during the countdown of the time established

with parameter H0, when the power is restored, the countdown will

be re-started with a max error of 30 minutes.

The function is activated on condition that:

• the temperature detected by the probe in the lower part of the

DHW tank is above the work set point during “normal” opera-

tion.

• the temperature detected by the probe in the lower part of the

DHW tank is above the work set point during “comfort” opera-

tion.

When the temperature of the lower part of the DHW tank reaches that

established with parameter H1, the heating elements remain on for

the time established with parameter H3, after which the function is

deactivated.

If there is a power cut during the countdown established with

parameter H3, when the power is restored the countdown will be re-

started from the beginning, but on condition that the temperature of

the lower part of the DHW tank has again reached that established

with parameter H1 (or when it reaches it again).

If the function is in progress and the instrument is switched off due to

the HOF1 and HOF2 parameters, the function is completed.