Carl Goldberg GBGA1088 User Manual

Page 7

7

AILERON SERVO INSTALLATION

Note: The following pictures may not exactly match

the hardware you are using. Always check the

radio manufacturer's instructions when installing

radio equipment.

1.

Collect the following items:

(4)Servo mounting screw (supplied with radio)

(1)Servo with rubber grommet (supplied with

radio)

(4) Servo extensions “6”

IMPO

RTANT! To ensure that any connections locat-

ed inside the wing will not come loose, either when

the wires are pulled, or during flying, always tape

them securely together with electrical tape.

4.

Making sure to use the correct servo for the

opening, attach the servo wire to the 6" exten-

sion and securely tape the connection.

Locate the string inside the aileron servo

mount, and the other end in the exit hole.The

hole in the top wing is just behind the front

cabane mount, The bottom wing has the hole

in the middle of the center section.

Tie the string to the aileron extension by loop-

ing it through the opening between the wires

on the plug and taping with masking tape.

5.

Grasping the string, SLOWLY pull until the

end of the 6" extension comes out of the hole.

Tape the extension securely to the wing, so

that it will not slide back in while you are work-

ing.

Secure servo with the screws supplied with

the radio.

Repeat for the other three wing servos.

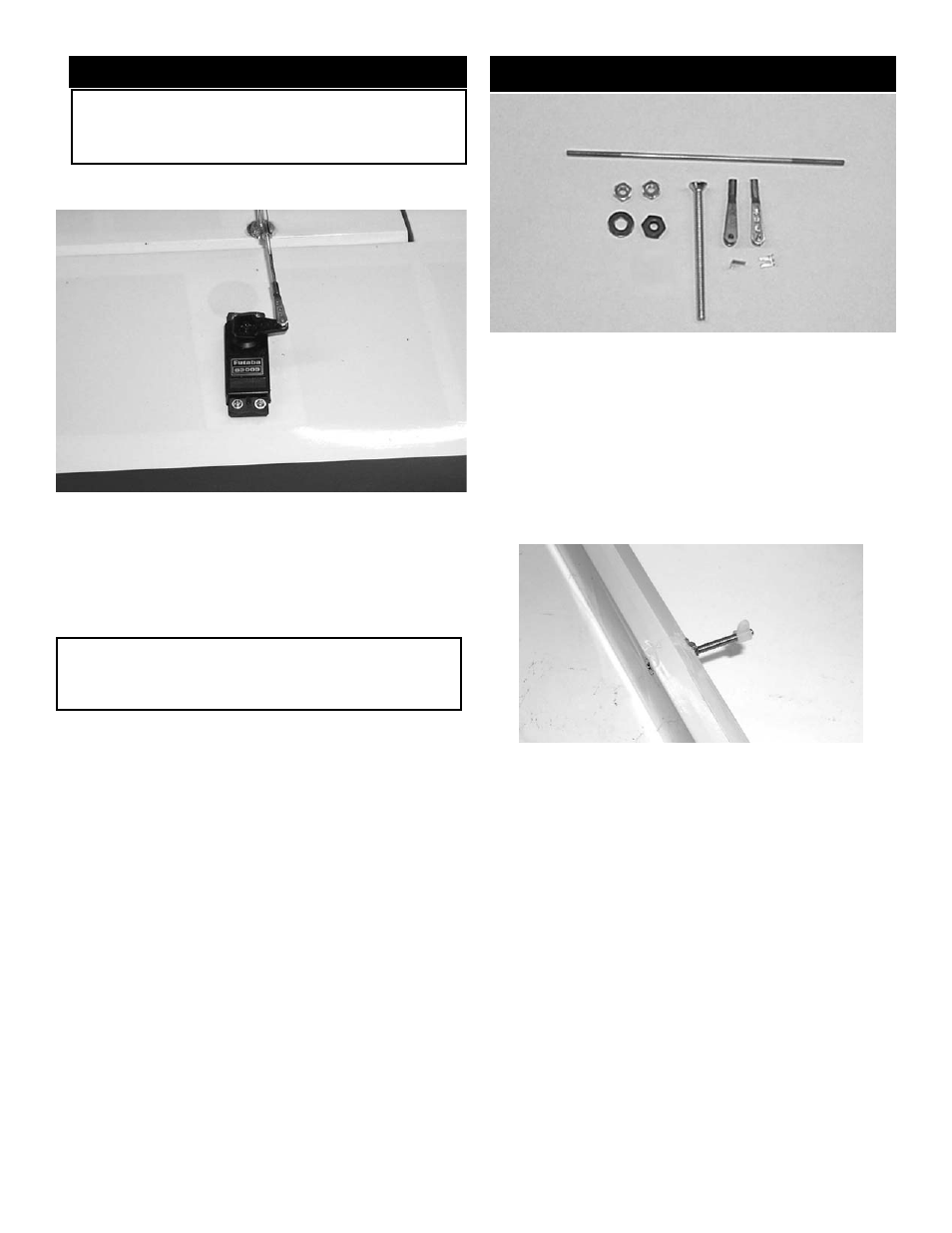

AILERON CONTROL HORN INSTALLATION

1.

Collect the following items

(8) 2-56 Golden Clevis

(8) Clevis Clips

(8) 2-56 Hex Nut

(4) 2-56 x 1-3/4” threaded both ends wire

(4) 6-32 x 2” Bolt

(4) 6-32 Hex nut

(4) #6 Washer

(4) 6-32 Horn Bracket

2.

With the aileron servo in place, make a mark

at a 90º degree angle to the trailing edge and

in line with the servo arm.

3.

Use the mark to locate the hard point installed

in the aileron( dowel with hole in middle).

4.

Using a 9/64" drill bit, open the hole in the

aileron through to the top side.

HINT: Drill the hole from the bottom half way.

Then drill down to the hole from the top of

the aileron.

5.

Insert the 6-32 x 2” screw from the top through

the aileron.

Place the #6 washer and the 6-32 hex nut on

the bolt and tighten. Make sure that you use

thread lock on the bolt and nut.

Screw the adjustable horn bracket on the

bolt.