Carl Goldberg GBGA1088 User Manual

Page 25

25

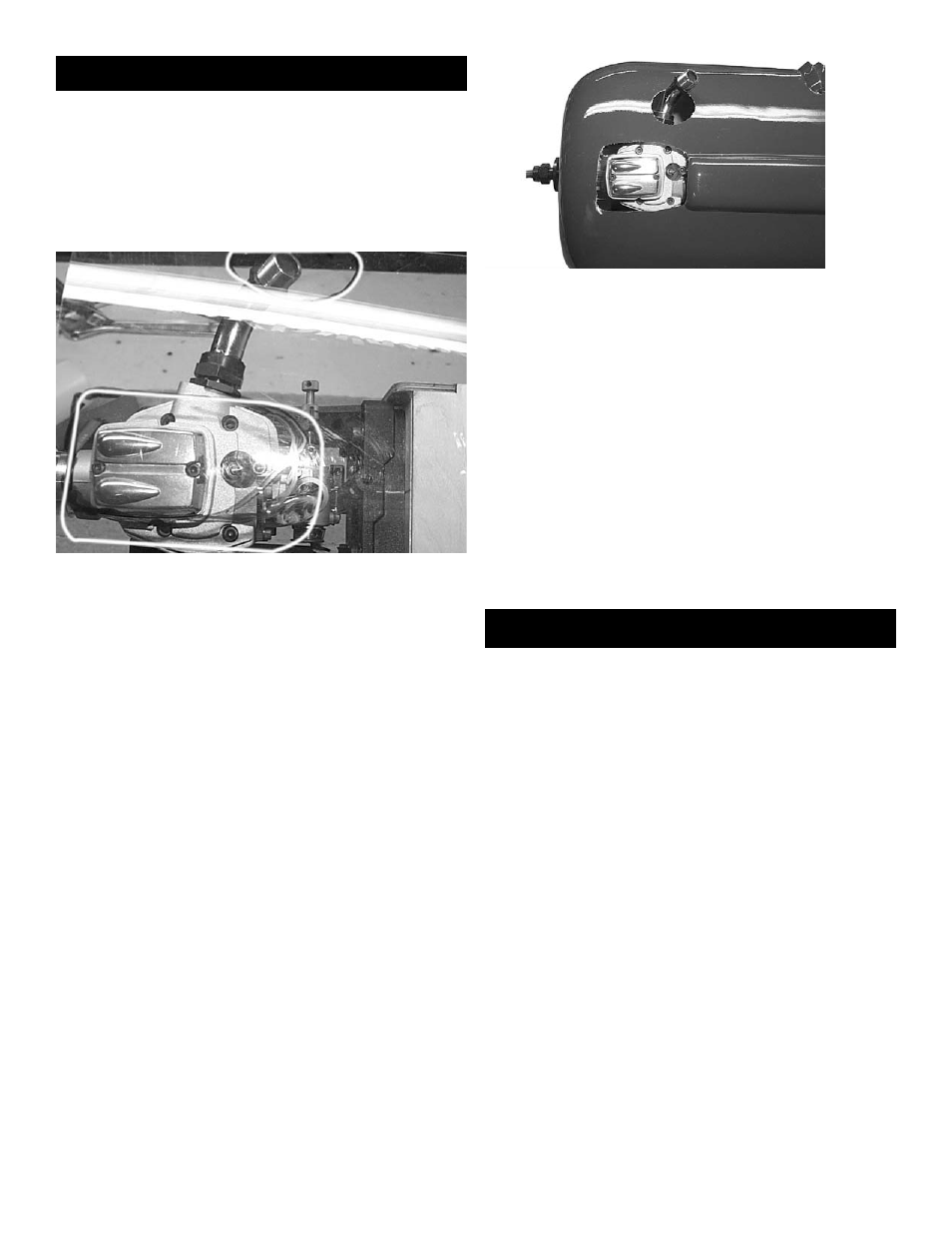

Cowl Mounting

1. Collect the following items.

(1) Cowl

(4) 4-40 x 1” Socket Head Bolt

(4) #4 Washer

(4) 1/4” pieces silicone tubing

(1) 4” x 12” Clear Plastic

2. Place the 4” x 12” plastic strip so that it is sit-

ting on top on the engine just past the cylinder

head.

Tape the plastic to the fuselage at the very end

with masking tape.

Mark a outline around the cylinder head and

you exhaust pipe.

Make a mark where the back of the plastic is

sitting on the fuselage.

Un-tape the plastic sheet from the fuselage

and cut out the plastic where you marked for

the engine.

2. Unscrew the engine from the motor mounts.

Place the cowl on the fuselage and fasten

using the 4-40 x 1” bolts and washers.

Re-tape the clear plastic sheet on the marks

that you made on the fuselage.

Make a mark where the cut out is on the cowl.

remove the cowl and cut out the openings.

NOTE: Start with small openings then slowly

increase the size till the cowl fits.

3. Use the same method to locate the holes for

the needle valve and any other openings you

need.

Servo Installation

1.

Collect the following items.

(1) 8mm x 17” wooden dowel

(2) pieces of 1/2” shrink tubing

(1) 5/32” x 19” nylon tubing

(2) 2-56 x 7-1/2” pushrods threaded one end

(1) 2-56 x 6” pushrod threaded one end

(1) 2-56 x 20” pushrod threaded one end.

(1) remainder of pull-pull cable from flying

wires

(4) cable swages(brass tubing)

(4) 2-56 rigging couplers

(8) 2-56 golden clevis

(8) clevis clips

(1) pushrod connector

You will need 7 servos for the plane. we

recommend a standard servo on the throttle and 4

standard servos are ok for the ailerons. The elevator

and rudder needs a 100oz of more servo. We used the

Futuba S9151 which is 132 oz.