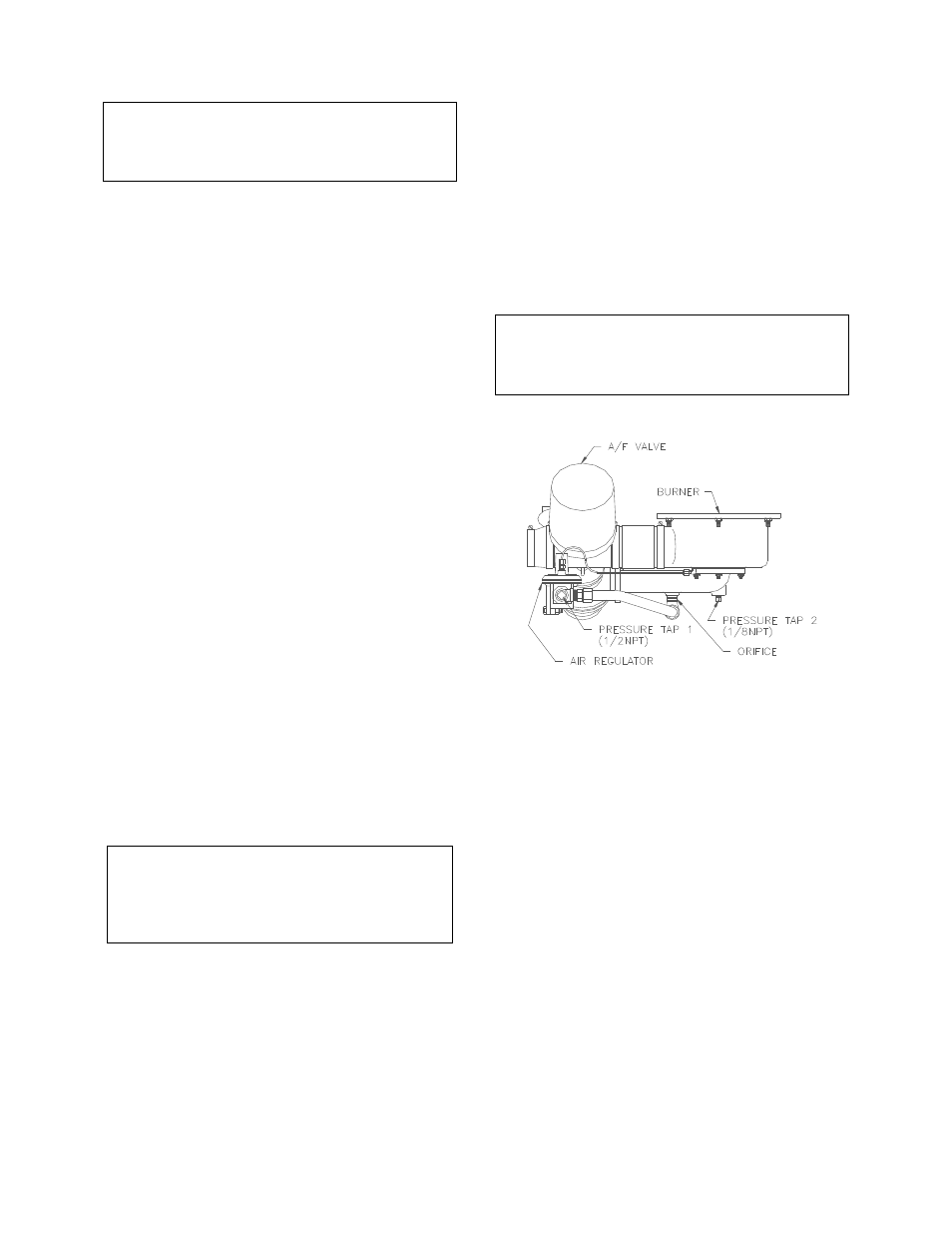

4 propane combustion calibration, Figure 4.5, Propane air differential pressure taps – AERCO KC1000 Heater 2002 User Manual

Page 33: Initial start-up

INITIAL START-UP

4-5

NOTE:

Adjust the inlet air shutter only at 100% firing

rate. Do not adjust the differential pressure

regulator.

25. Change the firing rate to 30%. Allow time for

the combustion analyzer to settle. Check the

measured oxygen reading to insure that it is

still within the range as per Table 1.

26. Continue this procedure until all oxygen

levels are within the ranges specified in

Tables 1, 2 and 3.

27. Record all readings on the AERCO start-up

sheet provided with each unit. Proceed to

paragraph 4.5.

4.4 PROPANE COMBUSTION

CALIBRATION

For propane units it will be necessary to install

an additional 8” W.C. manometer. This

manometer will be used to measure the

pressure drop across the air/propane mixing

orifice. After performing the setup procedures in

paragraphs 4,2.2 through 4.2.4, install the 8”

W.C. manometer as described in steps 1, 2 and

3 which follow.

1. Referring to Fig. 4.5, remove the 1/8” NPT

plug from the gas inlet pipe ahead of the

burner and install a 1/8” NPT barbed fitting.

2. Remove the 1/2” NPT plug from the tee

located after the air pressure regulator and

install a 1/2” barbed fitting (see fig. 4.5).

3. Attach the 8” W.C. manometer to the barbed

fittings installed in steps 1 and 2.

NOTE:

The combustion calibration data in Tables 1, 2

and 3 apply to both natural gas and propane

units. Therefore, refer to these Tables when

performing propane combustion calibration.

4. While performing the combustion calibration

procedure in paragraph 4.3, measure the

pressure drop across the air/propane mixing

orifice using the 0-8” W.C. manometer.

5. This reading should remain a constant 3.8”

to 4” W.C. throughout the operating range.

6. If the pressure drop is not within this range,

remove the cap from the air pressure regula-

tor.

7. Using a flat blade screwdriver adjust the

regulator until 3.8”-4.0” W.C. is obtained.

Clockwise will increase the reading and

counter-clockwise will decrease the reading.

8. If adjustments are made to this regulator it

will be necessary to recheck oxygen settings

at 16%, 30%, and 100% firing rates.

NOTE:

After an adjustment is made to the air regulator,

the cap must be put back on securely to obtain

an accurate reading.

Figure 4.5

Propane Air Differential Pressure Taps

4.5 UNIT REASSEMBLY

Once combustion calibration is set properly, the

unit can be re-assembled for permanent opera-

tion.

1. Set the

ON/OFF switch to the OFF position.

Disconnect the AC power supply from the

unit.

2. Shut off the gas supply to the unit.

3. Remove any regulator adjustment tools by

first pulling up the screwdriver blade to

disengage it from the regulator adjusting

screw, and then turning the tool out of the

top of the regulator.

4.

Apply a drop of silicone to the regulator

adjusting screw to lock its setting.

5. Remove the gasket from the tool and place it

back onto the regulator cap.