3 gear oil exchange, 1 carrying out a gear oil exchange, Maintenance – FRITSCH PULVERISETTE 13 premium line User Manual

Page 44

Material

Reference

value for max.

tightening

torque (Nm)

Density g/cm³ Abrasion

resistance

Use for mate-

rial to be

crushed

Order number

fixed disk:

Order number

movable disk:

Tungsten car-

bide 90.3%

WC + 9.5% Co

at least 50

14,8

Very good

Hard, abrasive

sample mate-

rial

13.2000.08

13.2010.08

Zirconium

oxide 94.5 %

ZrO2

approx. 20

6,0

Extremely

good

Medium-hard,

abrasive

sample mate-

rial for iron-

free grinding

13.2100.27

13.2110.27

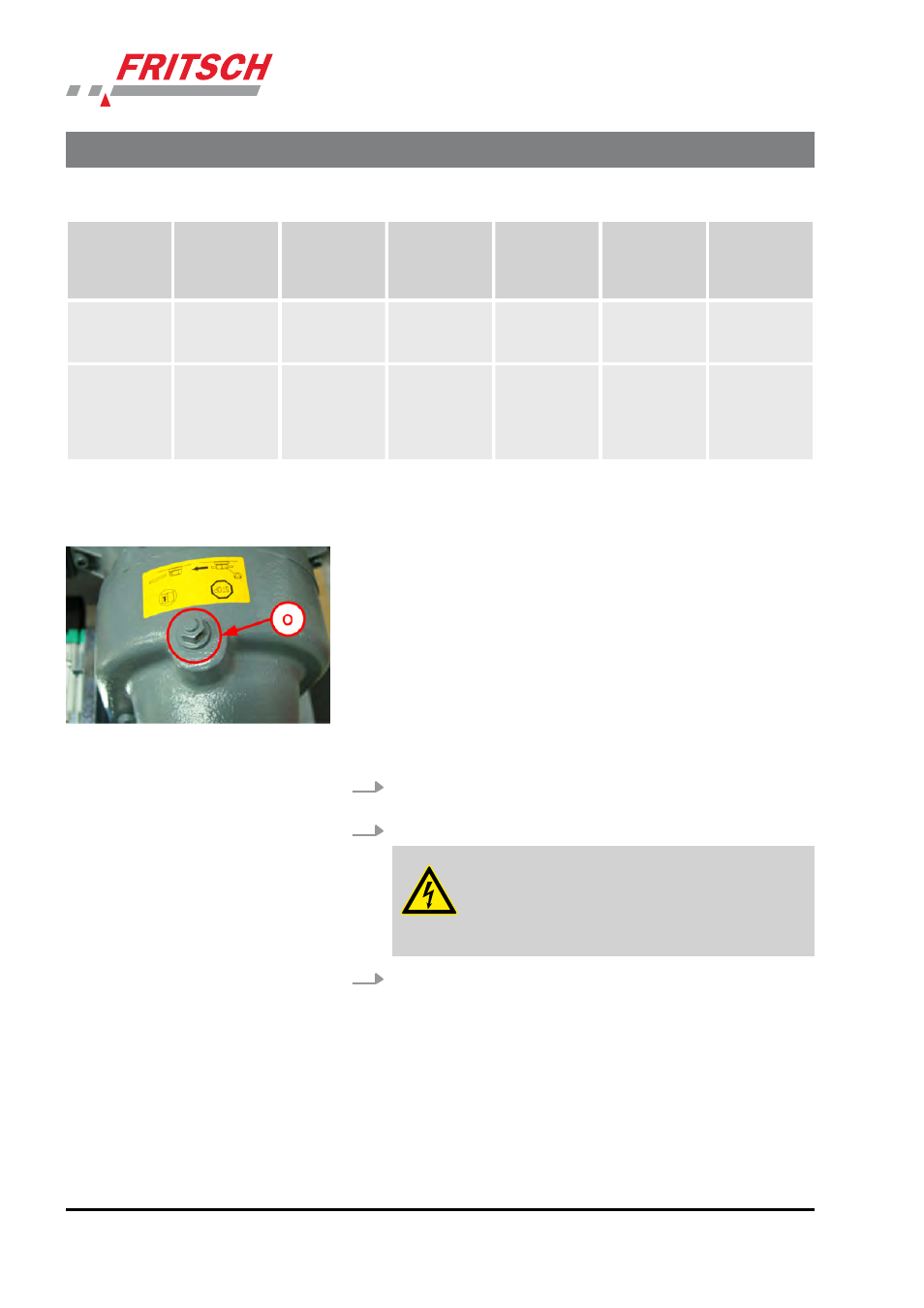

9.3 Gear oil exchange

The gears of the motor are filled with gear oil at delivery (ISO VG 220

Ord. no.: 85.0110.00). To change the transmission oil, there is a filler

screw (o) at the top of the gear housing. To access it, the housing cover

needs to be removed as explained in Ä Chapter 4.3 ‘Setting up’

on page 18.

The oil needs to be changed after about 5 years.

9.3.1 Carrying out a gear oil exchange

1.

Have the PULVERISETTE 13 premium line run for about 15 minutes

so that the gear oil inside warms up and drains better.

2.

Remove the mains plug.

DANGER!

Disconnect the mains plug from the mains and secure

the device against being unintentionally switched

back on.

3.

Disassemble the hood. (See Ä Chapter 4.3 ‘Setting up’

Maintenance

- 44 -