Feeder, Jaw crusher pulverisette 1 premium line, Accessories – FRITSCH PULVERISETTE 13 premium line User Manual

Page 35

7.2 Dosed sample feeding with the LABORETTE 24 vibratory feeder

To ensure a steady dosed feeding in of the sample material, you can

employ the LABORETTE 24 vibratory feeder in combination with the PUL-

VERISETTE 13 premium line . The feeder can be attached over the feeder

connection on the disk mill's back side. During grinding, it feeds the

sample material automatically to the device.

CAUTION!

Be careful when combining the PULVERISETTE 13 premium

line and the LABORETTE 24 for grinding as sample material

may fly out of the funnel of the disk mill. During grinding

therefore, only so much material should be fed via the

channel so that the funnel of the PULVERISETTE 13 pre‐

mium line is filled half full and no sample material can

escape from the grinding chamber. Afterwards, set the

feeding, so that the fill level in the funnel of the disk mill

remains constant.

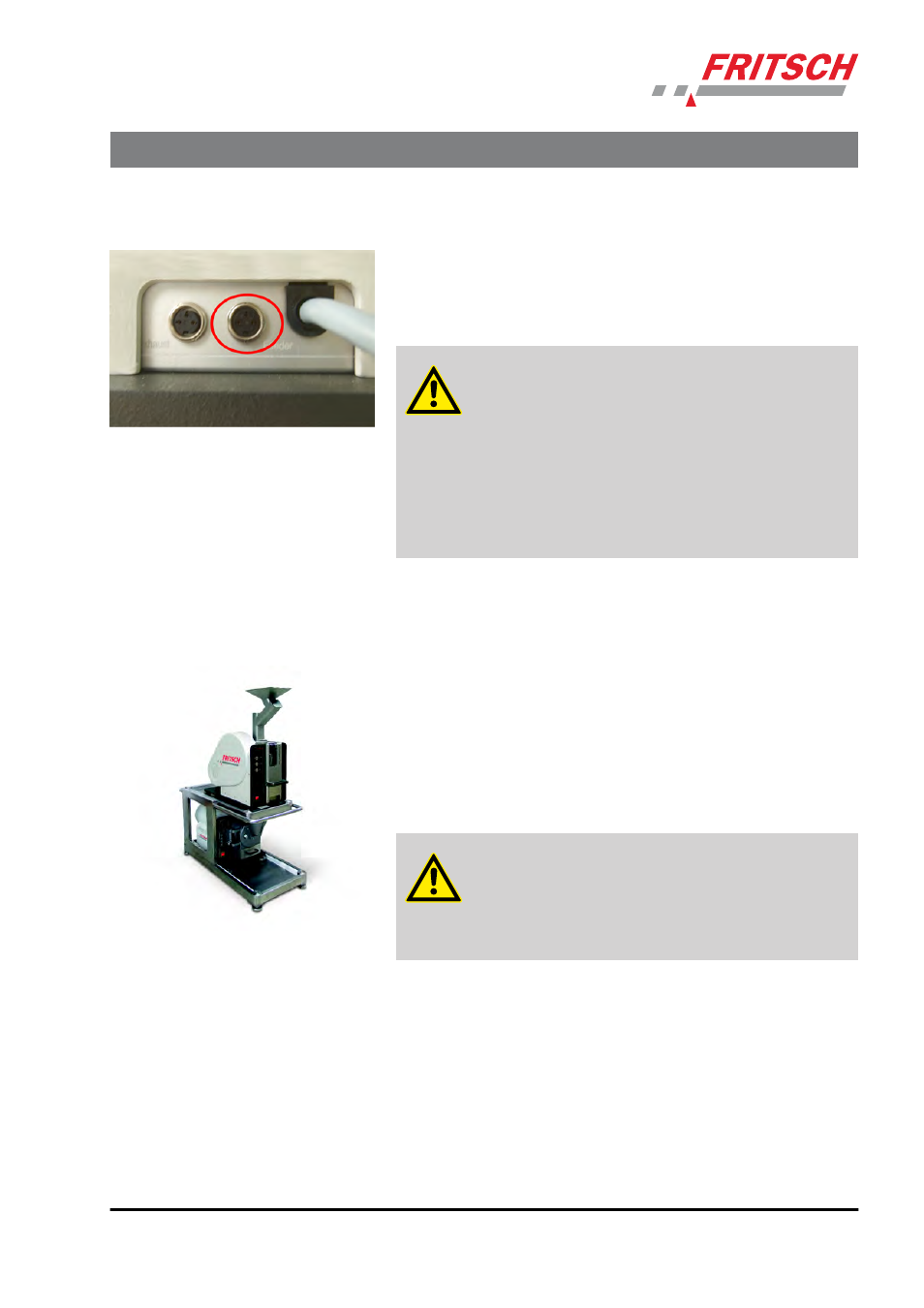

7.3 Comminution of coarse material in combination with the Jaw Crusher PULVERI-

SETTE 1 premium line

For comminution of coarse material for the subsequent use in the disk

mill, it is used in combination with the Jaw Crusher PULVERISETTE 1 pre‐

mium line.

The comminution is done in this combination in a single pass with 95 mm

(or 65 mm) feed size up to an average particle feed size (d

50

) of 0.05 mm.

The jaw crusher is placed on a mounting rack (order no. 43.6000.00) over

the disk mill. The material roughly crushed in the jaw crusher passes via

a hopper directly into the funnel of the disk mill.

CAUTION!

Feed in only as much sample material into the jaw crusher

as the PULVERISETTE 13 premium line itself can grind.

(Depends on gap width, comminution by batches with col-

lection container: max. 2 L sample material)

Accessories

- 35 -