10 taking samples, 11 final fineness, 10 taking samples 6.11 final fineness – FRITSCH PULVERISETTE 13 premium line User Manual

Page 32: Using the device

4.

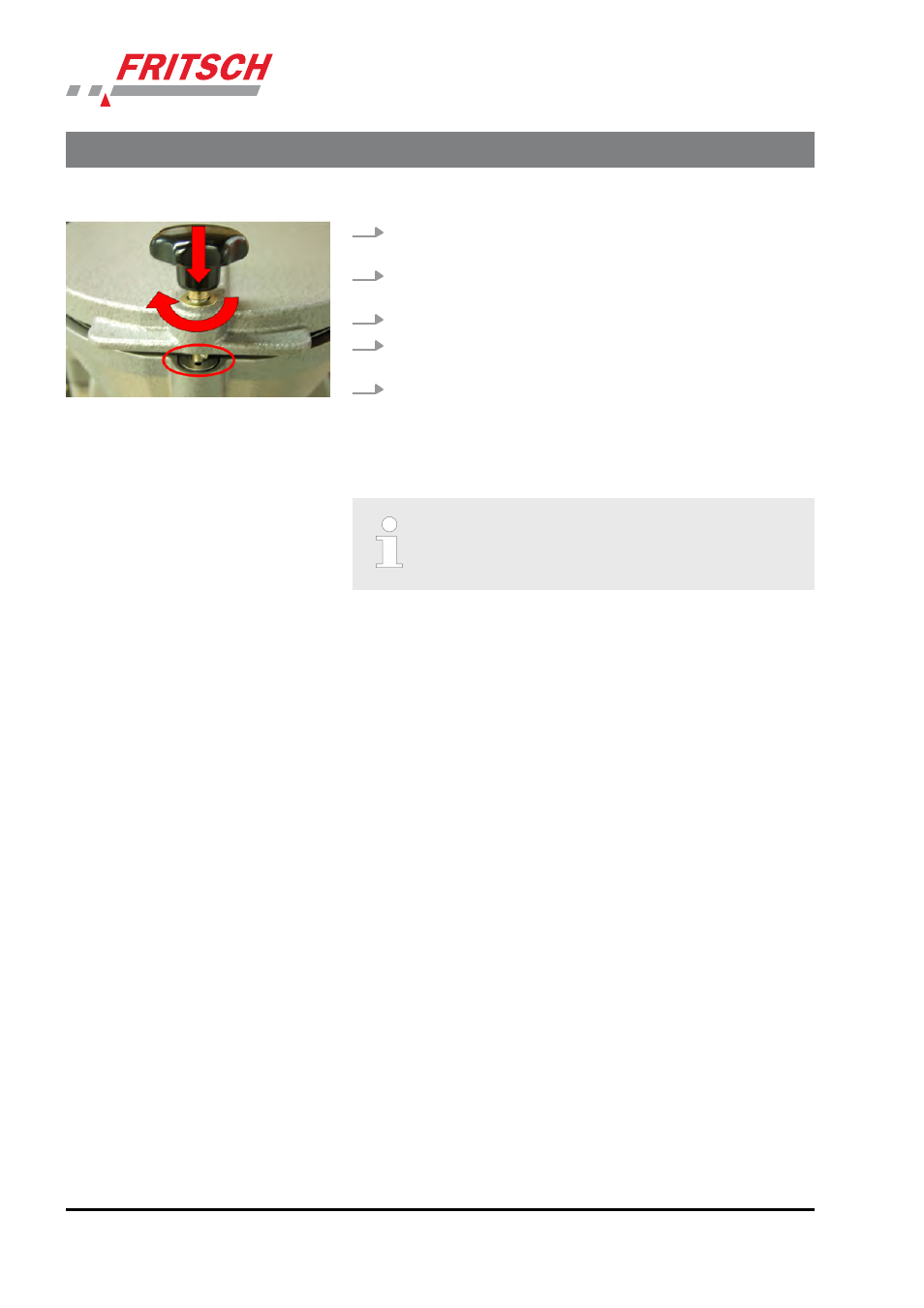

To close the lid, you have to press the pins on the quick closer into

the grooves on the funnel and lock it by a quarter turn clockwise.

5.

Observe the grinding process (grinding sound) and determine the

optimal filled in quantity. Repeat this for each new material.

6.

Do not refill more material until the grinding sound has lowered.

7.

Maximum fed in quantity depends on the grindability of the mate-

rial and the collecting volume of the grinding stock container.

8.

Put large lumps of material (up to 20 mm per edge) into the funnel

singly; close and secure the lid.

6.10 Taking samples

Depending on the quantity of the ground material, be sure

to use both hands when taking out the grinding stock con‐

tainer (10). Hazard of tipping!

6.11 Final fineness

The final fineness that can be achieved depends on the selected gap

width (approx. 0.05 mm to approx. 12 mm). The gap width determines

just one dimension of the individual particles in the fine ground material.

For example, breaking material may well contain greater dimensions in

one extension direction. Normally however, with this type of material,

the amount of samples with larger dimensions in this extension direction

is also reduced significantly after a second grinding pass.

Using the device

- 32 -