1 grinding disks, 2 exchanging the grinding disks (5 + 6), Ä chapter 9.2 – FRITSCH PULVERISETTE 13 premium line User Manual

Page 39: Maintenance

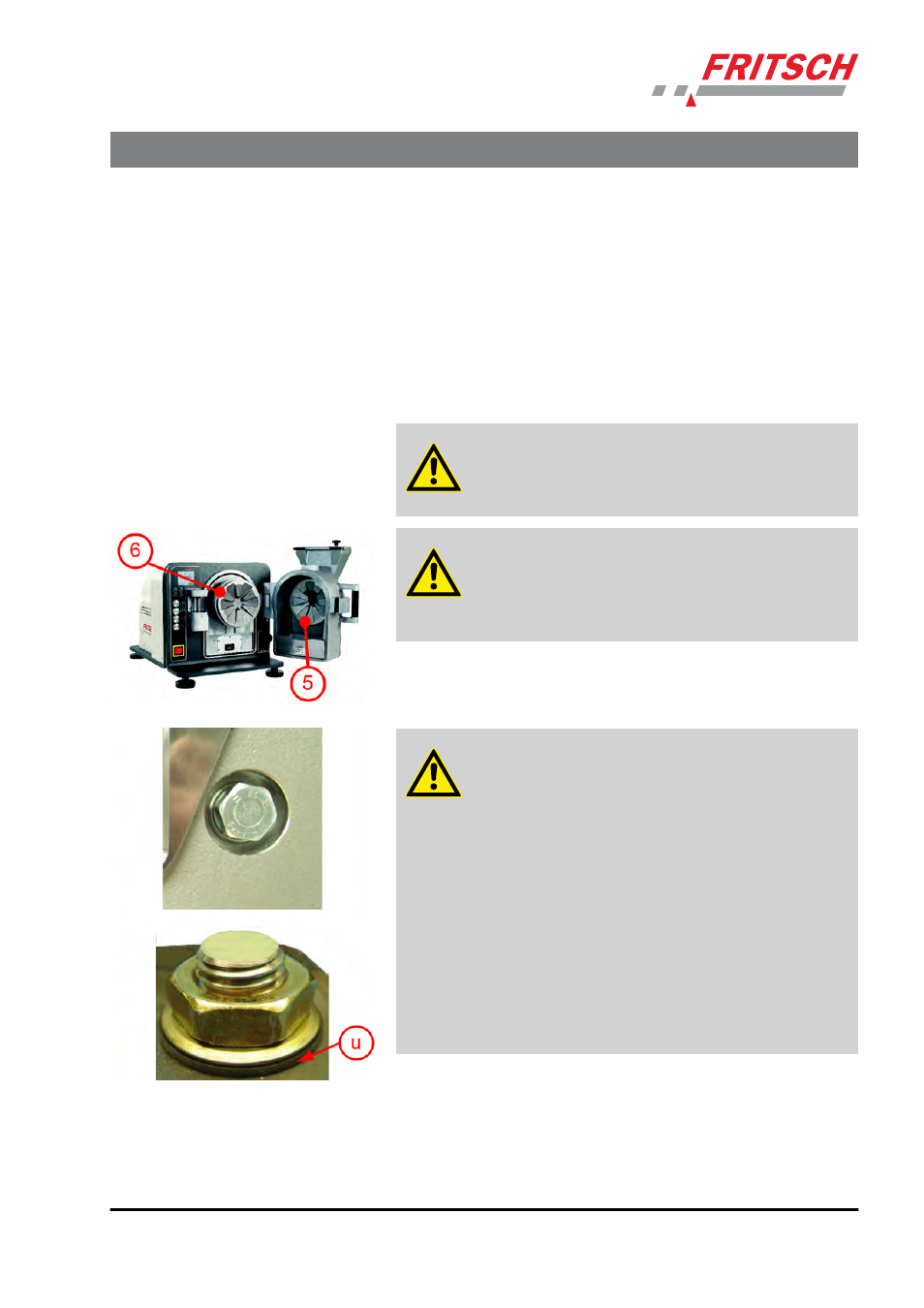

9.1 Grinding disks

The grinding disks wear down after a certain time, depending on the

material being crushed. Check their surfaces in regular intervals. For

changing the direction of rotation or exchanging the disks, observe the

information in Ä Chapter 6.5 ‘Revers mode’ on page 28 and as follows in

Chapter 9.2 ‘Exchanging the grinding disks (5 + 6)’ on page 39.

9.2 Exchanging the grinding disks (5 + 6)

CAUTION!

The device has to be connected to the mains to open the

grinding chamber and adjust the gap width.

CAUTION!

– Crushing hazard when exchanging the grinding disks.

– Secure the grinding disks against falling while

exchanging them.

CAUTION!

Clean the holder and the back of the disks thoroughly

before installing the new disks. This is very important in

particular when employing the ZrO2 disks as well as the WC

+Co disks, so that the disks are seated without tension and

parallel to each other.

When using the zirconium oxide grinding disks:

When tightening the nuts, it is important that the tight-

ening torque is not too great (see table) and is the same for

both nuts.

The ZrO2 grinding disks come with rubber washers (u) that

are placed under the steel washers. The nuts are tightened

then until the rubber washer is slightly squeezed out by the

steel washer. Thus a tightening torque of approx. 20 Nm is

ensured.

Maintenance

- 39 -