Cub Cadet P Series User Manual

Page 89

84

PK Series

1. Install thrust bearing and race assembly (34).

2. Install the block thrust washer (30).

3. Install block spring (29).

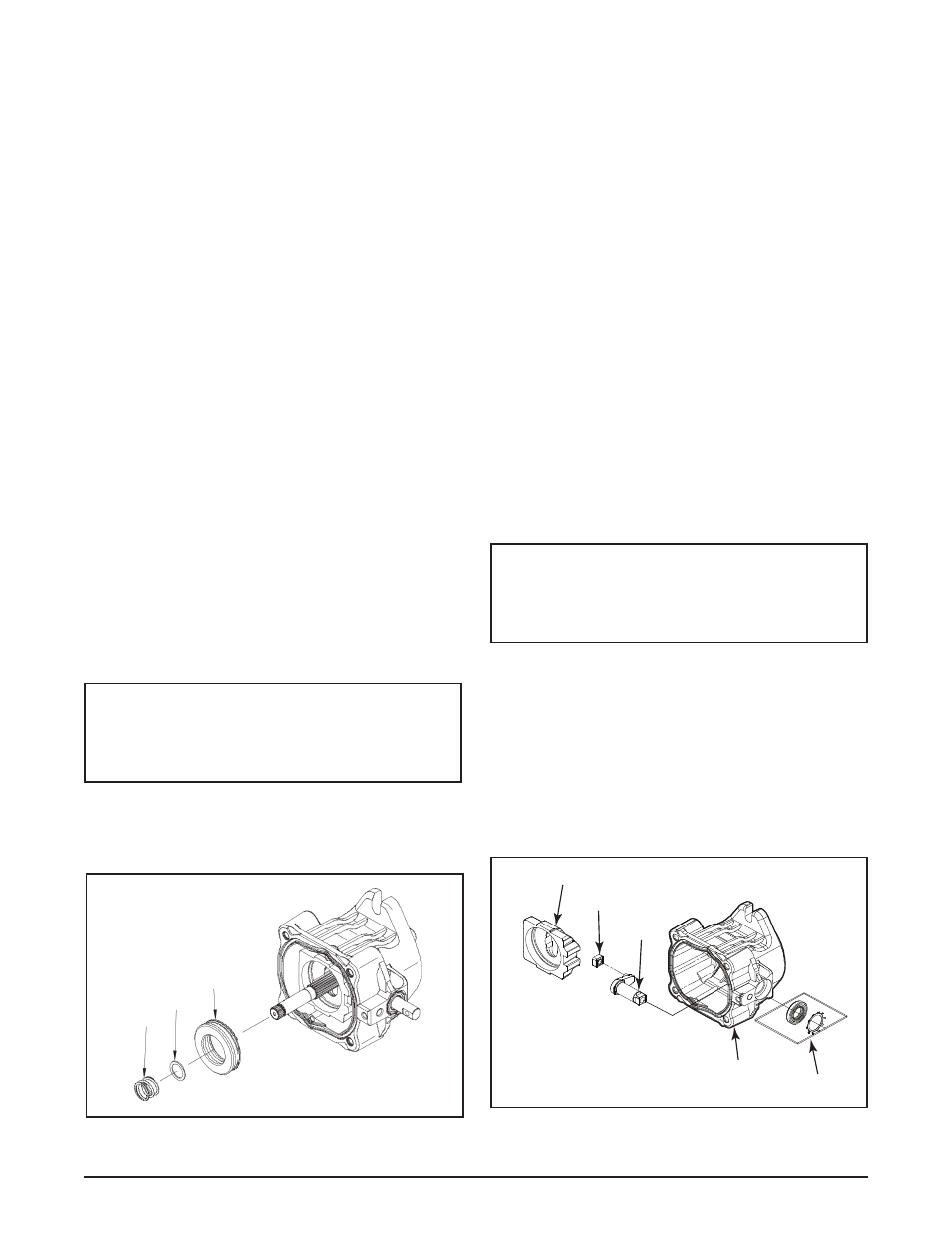

Refer to Figure 13.

Disassembly

1. Remove the block spring (29).

2. Remove the block thrust washer (30) and thrust

bearing (34).

Inspection

1. Inspect and replace the block spring (29) if it is

distorted or broken.

2. Inspect the running surface of the bearing races

for damage, nicks or unusual wear patterns. The

running surface may show evidence of minor

abrasion. This will be normal wear.

Inspect the bearings for free movement. Inspect

the bearing cage for distortion or damage.

Replace if necessary.

Assembly

REMOVAL, INSPECTION AND

ASSEMBLY OF BLOCK SPRING AND

THRUST BEARING

NOTE: The difference in race thick-

nesses: The thin race seats into the

swashplate (32). The thicker race will be

installed toward the piston noses.

Figure 13. Pump Block Spring and Thrust Bearing

Refer to Figure 14.

Disassembly

1. Remove the swashplate (32).

Inspection

1. Inspect the running surface of the bearing pocket

of swashplate (32) for damage, nicks or unusual

wear patterns. The running surface may show

evidence of minor abrasion. This is normal wear.

Inspect the cradle bearing side of the swashplate

(32) for damage. Replace if necessary.

2. Inspect the cradle bearings attached to the inside

of the housing (1) for normal wear patterns and

placement, and insure they are staked securely

in place. If the bearings are damaged, replace

housing (1).

REMOVAL, INSPECTION AND

ASSEMBLY OF SWASHPLATE AND

CRADLE BEARINGS

NOTE: The cradle bearings will have dis-

coloration due to normal wear. Under

normal circumstances, this will not war-

rant replacement.

Figure 14. PK Pump Swashplate and Cradle

Bearings

Assembly

1. Install swashplate (32) by holding trunnion arm’s

slot guide (38) with a flat tip screwdriver. Use

the screwdriver to hold the slot guide in place

while positioning the swashplate (32) onto the

cradle bearing in the housing (1).

2. Rotate trunnion arm (37) to verify that the

swashplate moves freely.

29

30

34

38

37

32

1

49