Checkline KXE User Manual

Page 3

– 3 –

1.0 Introduction

The KXE Warp Tension Meter is designed to measure tensions during warping and

weaving. The unique sensor configuration provided two 25 mm wide cylindrical roller

for the capture of two groups of yarns, one on each side of the sensor for measurement.

Therefore the sensor will be measuring 50 mm of ends while the process is running.

The electronic indicator provides for measurement and storage of the critical high and

low peaks that will be measuring in the weaving operation. These peaks can them be

analyzed and used for process evaluation. Stored data can be transferred to a PC and

analyzed using the FREE Tension Inspect software.

1.1 Models

KXE-20

0.5 – 20.0 daN measuring range.

KXE-50

0.5 – 50.0 daN measuring range.

1.2 Unpacking

Unpack the tension meter and inspect it for any shipping damage. Notices of defect

mustbe filed immediately, in writing, at the latest within 10 days on receipt of the goods.

– 26 –

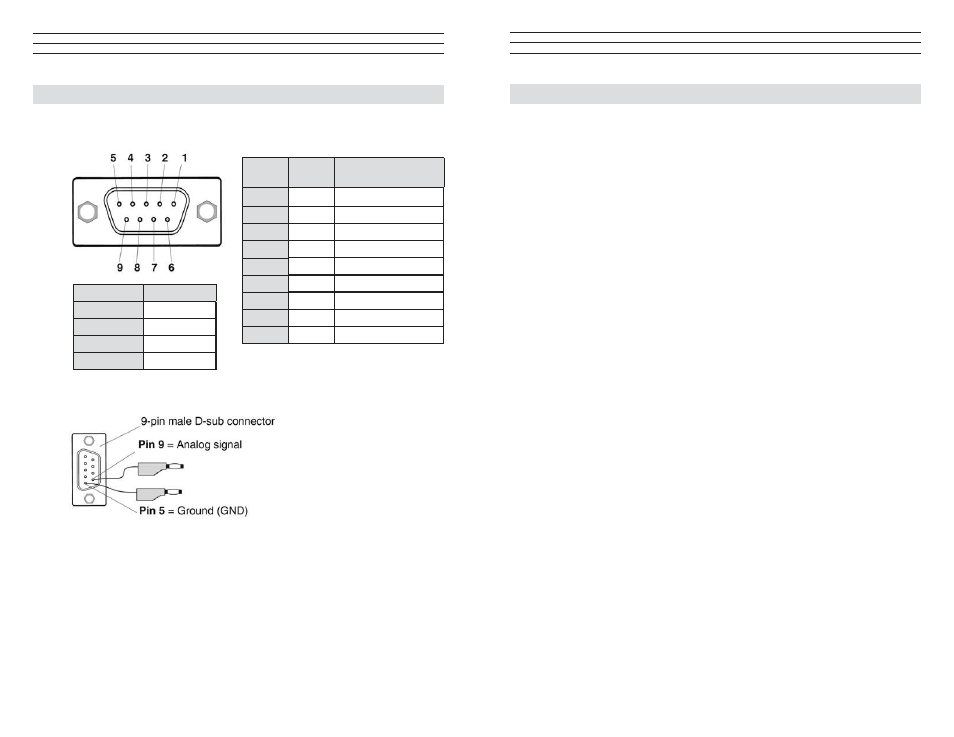

13.0 Pin Assignments

13.1 Pin Assignment and Signals of the Interface (9-Pin D-Sub Connector)

13.2 Pin Assignment of the Analog Cable (Option ETX-CA)

Signal

RS-232-C

Data Bit

Bit

Stop Bit

1 Bit

Parity

None

Baud Rate

19200

Pin

Number

Signal

Description

1

Not Assigned

2

TXD

1 Bit

3

RXD

None

4

Not Assigned

5

GND

Ground

6

Not Assigned

7

RTS

READY TO SEND

8

Not Assigned

9

2 V DC

Analog Signal