Checkline DTMX User Manual

Page 5

4.00 QUICK START INSTRUCTIONS

4.10 Setup

1. Insert a sample of the process material into the Thickness Compensator and

secure the ends of the sample under the Sample Holding Clips on each side

of the unit. Thickness Compensator is not used on the DTMX-200

Model.

2. Set the Material Rigidity Selector to "TEX” or "WIRE"

3. Set the Field Calibration Adjustment to "STD”

4.20 Operation

1. Turn the unit on by pressing the

key. Display should show zero

when unit is in measuring position. If

the gauge displays zero go to Step 3,

otherwise perform a Gravity Correction

Procedure (Step 2).

2. Position the DTMX into the measuring

position and perform a Gravity

Correction procedure (Zero):

Press the and keys

simultaneously, and hold until the display

shows “0” or “0.0”.

POWER

EXIT

POWER

EXIT

RECALL

5

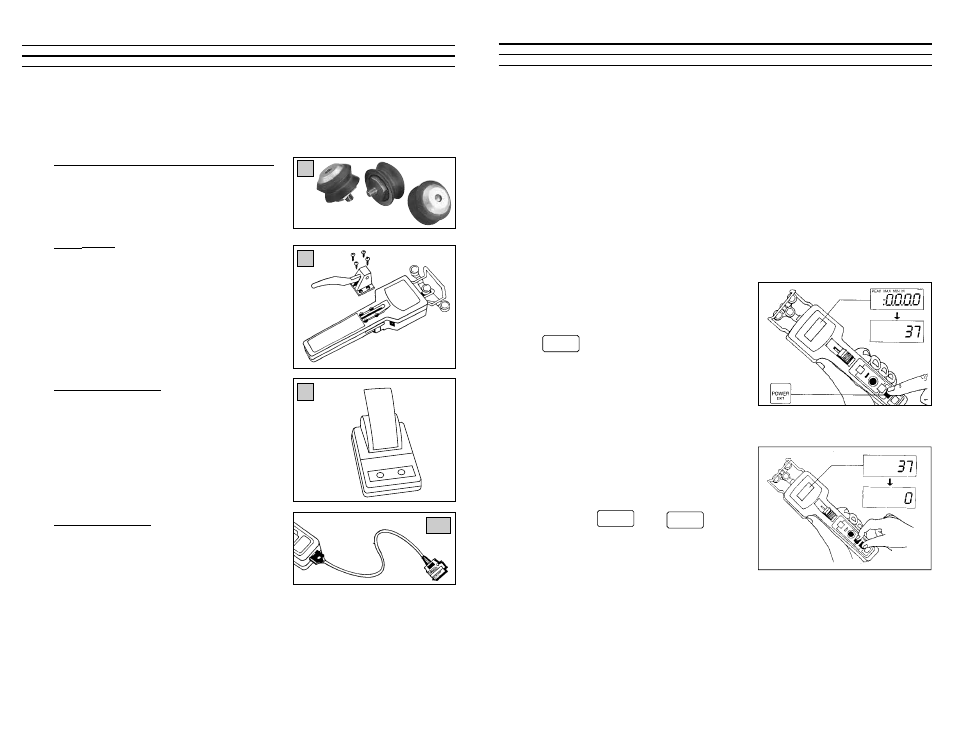

9.50 Options

9.51 Ultra-High Speed Roller Assemblies

For line speeds up to 5,000 m/min, specify

“U” roller guides.

9.52 Lever

For high tension ranges specify an “L” Lever

attachment to make it easier to push the

outer rollers forward for material acquisition.

9.53 Portable Pinter

The P-DTMX battery-powered, portable print-

er uses rechargeable batteries. It is supplied

with a 10 ft. connection cable, one roll of

paper and a 115 VAC charger.

9.54 Serial Cable

The CS cable is for connection to Personal

Computers. The 10 ft. cable is supplied with

DB9 and DB25 Serial connectors.

28

U

L

P

CS