Checkline DTMX User Manual

Page 10

10

5.30 Configuring Dip Switches

The DTMX is supplied with six (6) dip switches permitting the user to select

desired Display Update Rate, Memory Mode and Data Output Type as detailed

below.

To access the dip switches, the Thumbpiece and Slide Guide Plate must be

removed. Refer to access instructions below.

5.31 Accessing The Dip Switch Block

1. Turn the DTMX power off by pressing and holding the

key

for five (5) or more seconds. The display will go blank.

2. Using a small Phillips screwdriver, remove

the screw in the center of the Thumbpiece.

Remove the Thumbpiece and screw. The

Slide Guide Plate and screw will be visible.

3. Using a small Phillips screwdriver, remove

the screw at the bottom of the Slide Guide

Plate and remove plate.

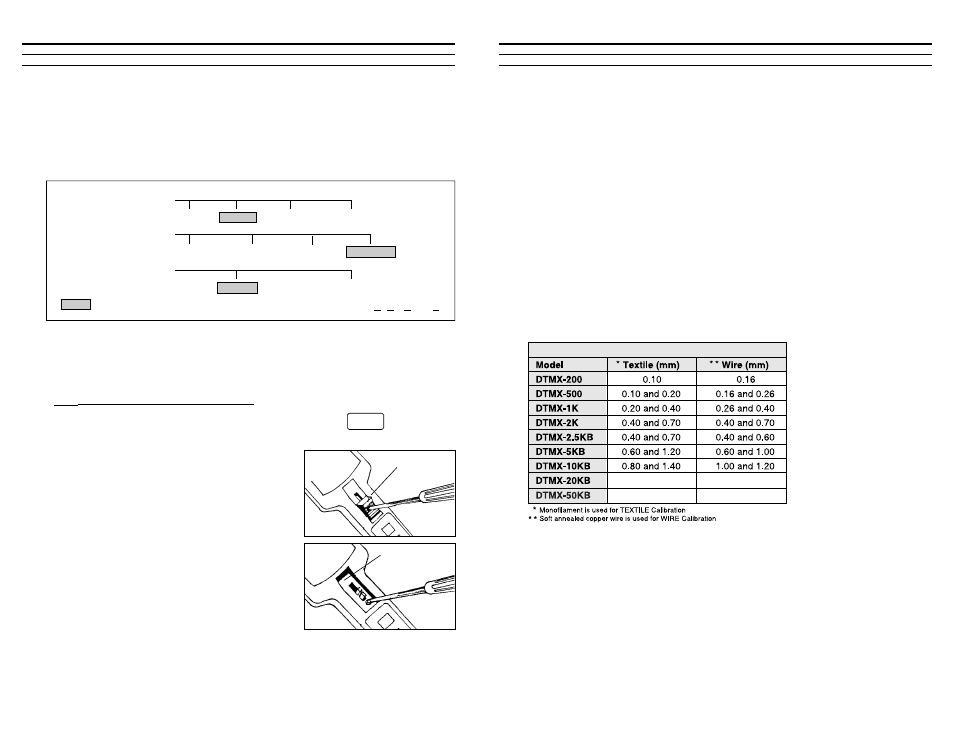

Display Update Rate

Memory Mode

Data Output Type

0.5 sec.

1 sec.

2 sec.

4 sec.

RS-232C

Digimatic

Standard

Standard-NAPO

On Demand

Continuous

= Denotes Factory Setting Standard N A P O = Standard Memory with No Auto Power Off

POWER

EXIT

Slide Guide

Plate

Thumbpiece

8.00 CALIBRATION

The DTMX is factory calibrated by taking a series of measurements with

known weight standards suspended from Factory Calibration Standard

Materials. The built-in microprocessor uses this calibration data with a com-

plex formula to calculate a calibration curve which takes into account material

rigidity, material thickness and orientation of use. The factory calibration

works well in most cases. However, if the process material to be measured dif-

fers significantly from the Factory Calibration Standard Materials (see table

below) or if the application requires the highest accuracy possible, perform a

Field Calibration Adjustment (refer to Section 8.20) or return the gauge to the

factory for optional Special Calibration.

Note: When ordering a Special Calibration, please supply a 10' sample of the

process material for calibration purposes.

Factory Calibration Standard Materials

Customer Sample

Customer Sample

Customer Sample

Customer Sample

23