Checkline DTMX User Manual

Page 12

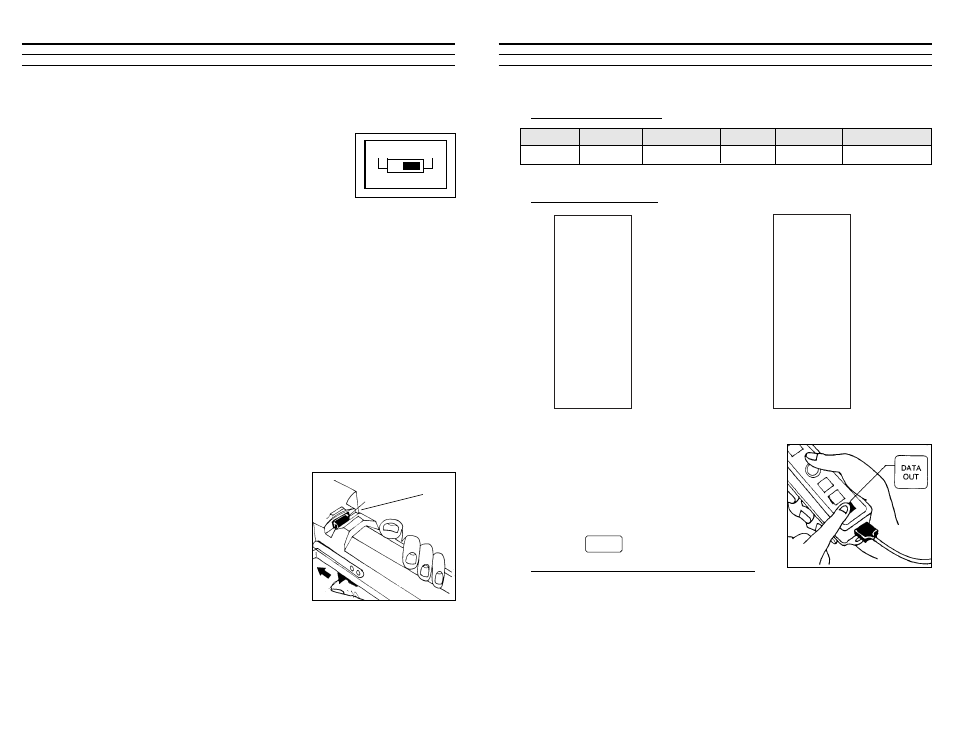

5.40 Material Rigidity Selector

The Material Rigidity Selector permits the user to set the

DTMX for use on Textiles or Wires. It is used in the com-

puter calibration formulas to provide the highest mea-

surement accuracy. If using a process material other than

a Textile or Wire, choose the setting which best matches

the rigidity (stiffness) of the process material. If uncertain which setting is

best, check the calibration in each position and choose the one providing the

best accuracy. Refer to Checking Calibration, Section 8.10.

The Material Rigidity Selector is also used to select a special calibration (SP1

or SP2) which is optionally available. Refer to Special Calibration, Sec. 8.30.

5.50 Thickness Compensator

When using the "three-roller” principle of tension measurement, an increase

in material diameter will result in an increased tension reading even when the

line tensions are unchanged. The DTMX is supplied with a proprietary

Thickness Compensation system which automatically shifts the outer rollers to

compensate for this effect. Additionally, the Thickness Compensator measures

the material diameter with an accuracy of 0.01 mm (0.0004 ") for use as a fac-

tor in the com-puter calibration formula.

The Thickness Compensator is located on the back of the instrument. When

the Thumbpiece is pushed forward, two metal plates (anvils) will separate cre-

ating a slot for insertion of the material sample.

NOTE: 1. Some monofilaments, wires and other

difficult-to-bend samples will need special prepa-

ration prior to insertion into the Thickness Com-

pensator. See Preparing Sample for Thickness

Compensator.

2. It is unnecessary to use the Thickness

Compensator on the DTMX-200 because the

range of material diameters used with this

model is inconsequential.

TEX

WIRE

SP1

SP2

12

Thickness Compensator

anvils

7.41 Printer Setup Data

7.42 Printer Setup Data

.

7.50 Serial Output — Computer

The DTMX can be connected to Personal Com-

puters or other serial recording devices for

downloading the recorded data and all calculated

statistics. Additionally, a user can request a data

point from a Host Computer (Poll Command) and

perform a Zero ("Tare"). See below for details.

Press the key to download recorded data.

Remote Host Computer Commands (Poll)

Request Data Point

“D” (ASCII capital letter “D")

Zero

“Z” (ASCII capital letter “Z”)

21

DATA

OUT

On-Demand

Data Logging Mode

Continuous

Data Logging Mode

STATISTICS

UNITS g

DATA 12

MAX 154.2

MIN

101.5 AVG

137.7

DEV 13.77

DATA

1 101.5

2 120.7

3 140.7

4 133.9

5 135.2

6 136.8

7 140.5

8 146.4

9 147.4

10 146.4

11 148.6

12 154.2

**

END

**

STATISTICS

UNITS g

DATA 12

MAX 154.2

MIN

101.5 PEAK

157.5

AVG 137.7

DEV 13.77

DATA

1 101.5

2 120.7

3 140.7

4 133.9

5 135.2

6 136.8

7 140.5

8 146.4

9 147.4

10 146.4

11 148.6

12 154.2

**

END

**

Signal

Baud Rate Word Length Parity

Stop Bits EOL Delimiter

RS-232C

4800

8-bit

None

2-bits CR + LF