Checkline ETW User Manual

Page 9

Electromatic Equipment Co., Inc.

-12-

4.0

WRENCH CALIBRATION

Calibration is achieved using four Measuring Points, namely 10%, 20% , 60% and

100% of Maximum Span of the Wrench. In Calibration Mode the Wrench will

automatically display these Measuring Point Values initially for the Right Hand and

then for the Left Hand. All Products should be 1% accurate.

Calibration Mode is only accessible through the Master & Distributor Versions of the

PC Front End. The End User cannot access the Calibration Mode. Please ensure

that certified calibration systems such as a Norbar ISO 1000 Transducer system are

used when calibrating the Torque wrenches, These devices are themselves

accurate to 0.25%

Note : De-stressing wrench implies that the wrench is torqued to it's maximum span

4.1

Calibrate Mode

Note: Ensure date & time on wrench are correct

1. Connect wrench to PCFE software and Click the Activate Calibrate Button

2. Press MENU on the Wrench to scroll to Calibrate Mode. Place Wrench onto

Calibration Unit. De-stress on the CW (Clockwise) direction

3. Press OK to activate Calibrate Mode (The Wrench OLED will now display a

reading of 10% of the Maximum Span of the Wrench)

4. Apply Torque to the Wrench until the Reading on the Calibration Rig is equal to

the Reading on the Wrench (10% of Maximum Span)

5. Press OK to confirm that the First Point of Calibration is now set

6. Now Measurement Point No.2 (20% of Maximum Span) will appear on the

Wrench OLED Display. Therefore repeat Steps No.4 & No. 5

7. Now Measurement Point No.3 (60% of Maximum Span) will appear on the

Wrench OLED Display. Therefore repeat Steps No.4 & No. 5

8. Now Measurement Point No.4 (100% of Maximum Span) will appear on the

Wrench OLED Display. Therefore repeat Steps No.4 & No. 5

9. Repeat Step No's 1 to 8 for the Left Hand calibration

10. Once calibration is complete select Trac mode on wrench. On the Left hand side

check wrench accuracy at 20%, 60% and 100% according IS06789-2003. Now

De-stress on Right hand side and repeat step 10

Electromatic Equipment Co., Inc.

-9-

3.9

Set Mode - Just Move Preset

This allows the user to change the default Just Move Angle to any Angle between 1

and 10 degrees - The operator Can do this using the PCFE or using the Wrench.

1. Press MENU to Scroll to Set Mode

2. Press OK to select and UP or DOWN to select Just Move Preset

3. Press OK to select Just Move once it's high-lighted green

4. Use UP or DOWN ke ys the to select between 1 and 10 degrees and press OK

5. Use UP or DOWN to select Just Move and the default angle will be changed

3.10

Just Move

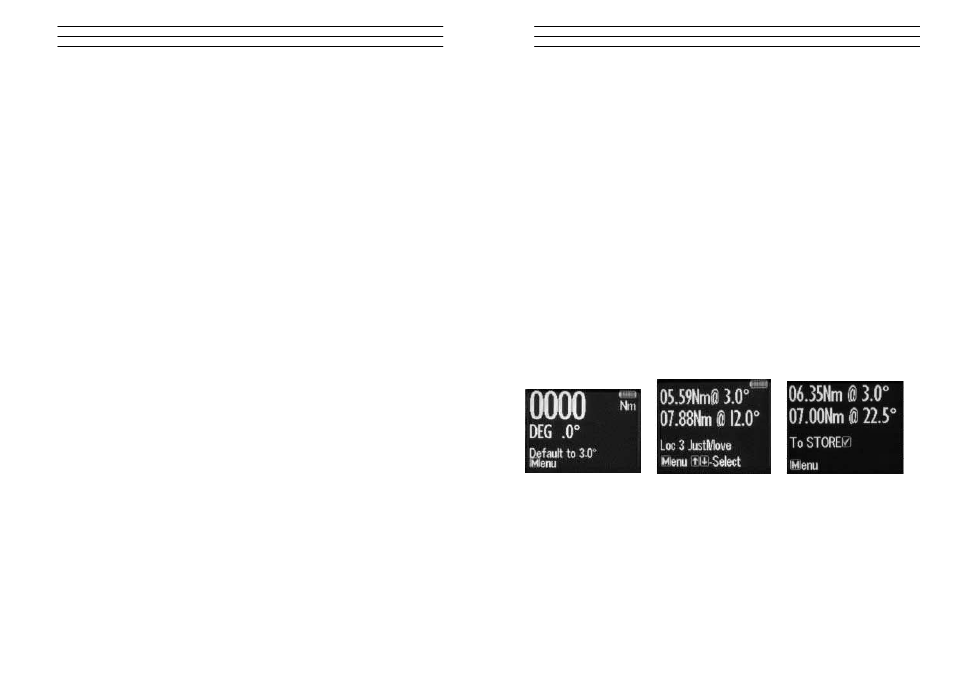

This function will display the Torque that was applied after 3 degrees of movement,

It will also show the final Torque and angle that were applied by the user. The

screen will change to Red once the Just move Angle threshold is passed and the

Buzzer will sound. The user can set the Just move degree in the "Set" menu option

or using the PCFE software. The Final torque and final Angle that was achieved will

also be displayed as shown. The default Just Move Angle is 3 degrees.

1. Press MENU to Scroll to Just Mo ve Mode

2. Press OK to select Just Mode and then apply Torque and Angle

3. Press OK to store the 3 degree Torque Value and Final Torque and Angle value

If Storage is not required then apply New Torque and Angle measurement

Just Move Default to 3 degrees Just Move Measurement

Just move result

3.11

Just Angle

This function will display the Peak Torque and Peak angle that were applied during

the Torque operation. The user can store the result at the end of each

measurement.

1. Press MENU to scroll to Just Angle and OK to select

2. Take a Torque and Angle reading

3. Press OK to store the result or apply another torque to continue