Checkline ETW User Manual

Page 7

Electromatic Equipment Co., Inc.

-14-

4.5

Wrench Data Transfer Protocol

General

The data transfer protocol allows measurement data along with the associated

date/time stamps and pre-set limits to be transferred from the wrench to other

equipment such as a PC or a PLC controller.

Data can be transferred in either ASCII or binary formats and data transfer can be

on a measurement by measurement basis or as a complete upload of internal

memory.

Data Link Settings

All data is transferred in 8 bit bytes, single start bit, single stop bit, no parity at a

speed of 9600 bits per second.

ASCII data transfer

For this the ASCI menu item must be selected on the wrench.

Individual measurement transfer

This is initiated by transmitting the ASCII character ‘m’ to the wrench. Once the

wrench receives this it remains in individual measurement transfer mode until it

powers down. Data can be transferred from the wrench whenever the ‘Store?’

prompt is ticked in peak or preset mode.

The data format is as follows:

Day, Month, Hour, Minutes, Torque value, Torque units, Preset index, Preset high

setting, Preset low setting, Preset nominal value, Preset units

Each item is separated by a comma and can be used to feed a CSV spreadsheet

file. In peak mode the pre-set values (high, low and nominal) are set at 0.

Block transfer

This is initiated by transmitting the ASCII character ‘b’ to the wrench. Once the

wrench receives this it transfers the entire data memory contents to the external

device. The data is separated into individual measurements containing the date/time

stamp, measured value and pre-set data, as described in the data format above.

The first measurement data are transmitted immediately after reception of the ‘b’

character. After each measurement data are transmitted the wrench waits for a

‘ready to receive’ signal in the form of the ASCII character ‘r’. Once this is received

the next measurement data are transmitted. When all memory data has been

transmitted the wrench will respond with the ASCII character ‘e’.

Electromatic Equipment Co., Inc.

-7-

3.3

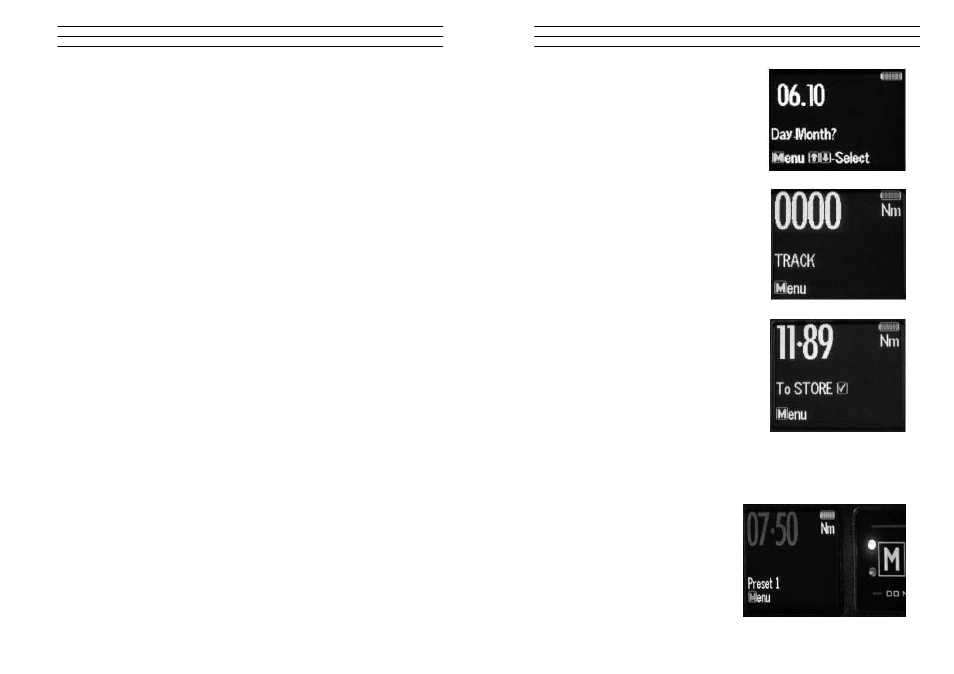

Date Mode - Keypad Function:

1. Press MENU to Scroll to the Date Menu

2. Press OK to enter Date Menu

3. Press UP or DOWN to to Set the min/Hour

4. Press OK to Confirm

To Set Day / Month / Year - repeat Steps 3 & 4

3.4

Trac Mode

As Torque is applied to the Wrench it will actively

display the applied Torque reading to the Max

Span of the Device. On removal of the Torque

Load the display will return to Zero.

1. Press MENU to Scroll to Trac Mode

2. Press OK to operate in Trac Mode

3.5

Peak Mode

In Peak Mode the Torque Reading will remain

Displayed when the Torque Load is removed. The

User has the option to store the reading in Memory.

If storage of the reading is not required the User

may continue to the next measuring task.

1. Press MENU to Scroll to Peak Mode

2. Press OK to select Peak Mode and then apply

Torque

3. Press OK to store the Peak Value Recorded if

required.

If Storage is not required then apply New Torque

3.6

Set Mode

This mode allows the user to set the limits for

Torque, Just Move and Torque and angle.

The operator can choose to set Torque values

by % or by tolerances. The OLED display will

be Green approaching Preset tolerances and

will change to Red if exceeded.